- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V or 380V

-

Dimension(L*W*H):

-

adjustable

-

Weight:

-

100 KG

-

Power:

-

15-70Kw Depends

-

Working Temperature Range:

-

3-35

-

Name:

-

TONSEN 1000 liter wort cold liquor tank water chiller

-

Application:

-

Fermenter Cooling

-

Ice tank Polishing:

-

0.4-0.6um/Mirror Polished

-

Insulation material:

-

Polyurethane 80-100 mm

-

Material:

-

Stainless Steel 304/316

-

Size:

-

930*520*975mm

Quick Details

-

Condition:

-

New

-

Place of Origin:

-

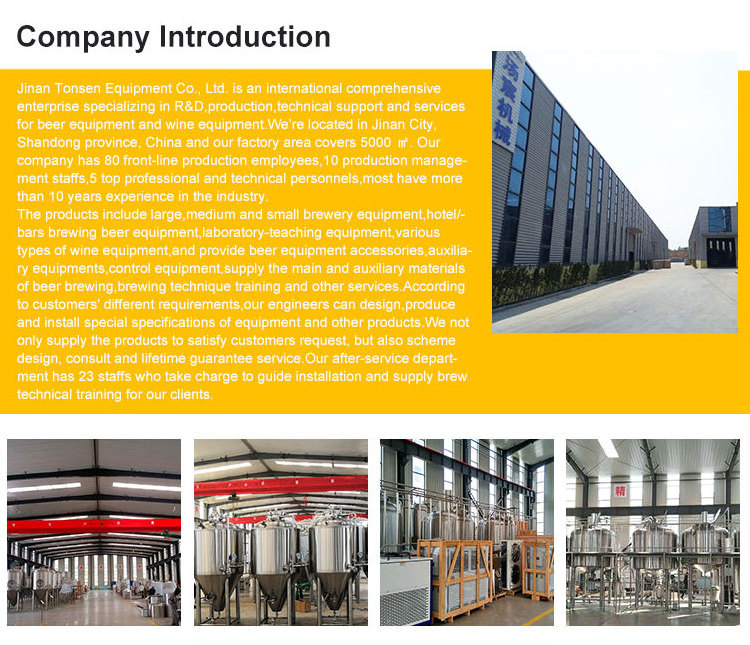

Shandong, China

-

Brand Name:

-

TONSEN

-

Voltage:

-

220V or 380V

-

Dimension(L*W*H):

-

adjustable

-

Weight:

-

100 KG

-

Power:

-

15-70Kw Depends

-

Working Temperature Range:

-

3-35

-

Name:

-

TONSEN 1000 liter wort cold liquor tank water chiller

-

Application:

-

Fermenter Cooling

-

Ice tank Polishing:

-

0.4-0.6um/Mirror Polished

-

Insulation material:

-

Polyurethane 80-100 mm

-

Material:

-

Stainless Steel 304/316

-

Size:

-

930*520*975mm

TONSEN 1000 liter wort cold liquor tank water chiller

Products Description

Brewery Cooling System used to brew beer locally. It is one important step for beer making.

The cooling system includes Chilled Water Tank, Refrigerating Machine and Other Line Valves Equipment. Beer refrigerating system mainly used for the cooling of wort and fermentation. The chiller that we adopt comes from the famous china brand which could keep the stable quality and enjoy more better-refrigerating effect. The optimum allocation of the refrigerating system can greatly reduce the wastage of energy, ensure the stable operation of beer brewed.

The cooling system includes Chilled Water Tank, Refrigerating Machine and Other Line Valves Equipment. Beer refrigerating system mainly used for the cooling of wort and fermentation. The chiller that we adopt comes from the famous china brand which could keep the stable quality and enjoy more better-refrigerating effect. The optimum allocation of the refrigerating system can greatly reduce the wastage of energy, ensure the stable operation of beer brewed.

|

SPECIFICATIONS FOR BREWING EQUIPMENT --- Fermentation System

|

|

|

||

|

Cooling System

Or Refrigerating System |

1. Chiller

2. Glycol Tank 3. Ice Water Pump 4. Insulation Pipe 5. Cold Media Pipes ETC. |

1. Glycol tank capacity: based on the requirement

300-6000L 2.Insulation: polyurethane, TH=80mm 3.Interior thickness:3mm, exterior thickness:2mm 4. Equipped with liquid level meter 5.Top-mounted manhole 6.Inner tank mechanical polishing and out plate surface protection ribbon polished on welds 7.100%TIG welding with pure argon gas 8. Material: SUS304, brushed outer shell |

||

|

|

|

|

||

|

|

|

|

||

|

|

|

|

||

Details Images

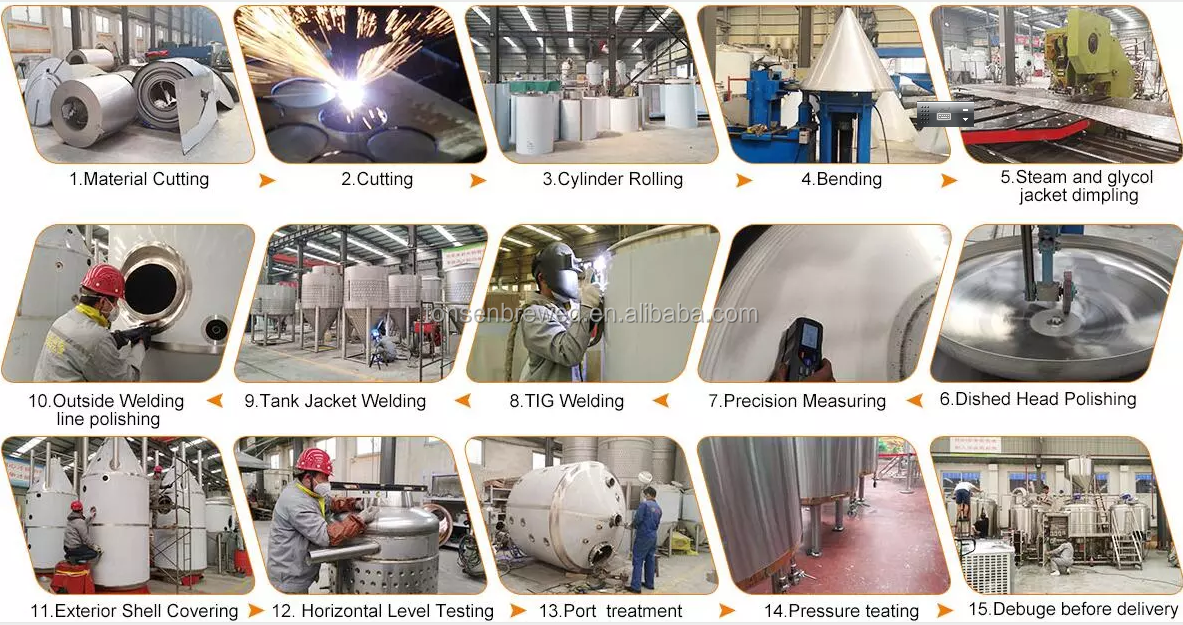

Manufacturing Technique

Certificates

Customer Visit

Installation Cases

Canada 10HP

Chiller Fermentation Tanks

French 6HP Chiller for Fermentation Tanks

Exhibition Tonsen

Packaging & Delivery

Service & Feedback

Pre-sales Service

Technical Drawing

We will offer technical drawings of each tank based on the equipment layout.

Layout design

Send us your building floor plan, or the sketch, or tell us the size(length, width, height), we will offer you an equipment footprint according to your requirement.

3D Drawing

We will 3D effective sketch to make sure you have a more intuitive experience.

After-sales Service

WARRANTY

1.Main product

equipment

for 3 years and auxiliary parts for 1 year.

2.Lifetime repair guarantee.

3.All spare parts and wearing parts are attached with the machinery for free.

SERVICE

2.Lifetime repair guarantee.

3.All spare parts and wearing parts are attached with the machinery for free.

SERVICE

1.Free consultation service before,during,and after sales.

2.Project planning and design the layout service.

3.Free debugging instruction of equipment until everything is functional.

4.Management of equipments' long distance shipping from seller's factory to named pord or station by buyer.

5.Training of equipment maintenance and operation personally.

6.New production techniques.

2.Project planning and design the layout service.

3.Free debugging instruction of equipment until everything is functional.

4.Management of equipments' long distance shipping from seller's factory to named pord or station by buyer.

5.Training of equipment maintenance and operation personally.

6.New production techniques.

Customer Feedback

FAQ

1.Q: Can you do OEM or ODM?

A: Yes, we can do.

2.Q: How to control temperature ?

A:PLC or digital display meter can control the temperature via connecting with the PT100 sensor.

3.Q: Is possible to supply installation in our country ?

A: Yes, we could supply engineer to supply installation guidance and training.

4.Q: Can your factory produce equipment according to our drawing or samples?

A: Yes, we can do.

A: Yes, we can do.

2.Q: How to control temperature ?

A:PLC or digital display meter can control the temperature via connecting with the PT100 sensor.

3.Q: Is possible to supply installation in our country ?

A: Yes, we could supply engineer to supply installation guidance and training.

4.Q: Can your factory produce equipment according to our drawing or samples?

A: Yes, we can do.

Hot Searches