- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customizable

-

Dimension(L*W*H):

-

customized

-

Weight:

-

12000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

installation guidance:

-

available

-

Flowchart drawing design:

-

available

-

Foudation drawing:

-

available

-

Product name:

-

Tin Ore Processing Plant(Alluvial ore and rock ore)

-

Machines types:

-

Washing machine, crushing machine, gravity separation machines

-

Capacity:

-

Customizable, no limit

-

Recovery rate:

-

80% to 90% depends on raw ore grade

-

Price:

-

Best factory price

-

Other auxiliary equipment:

-

available

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

JXSC

-

Voltage:

-

Customizable

-

Dimension(L*W*H):

-

customized

-

Weight:

-

12000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

installation guidance:

-

available

-

Flowchart drawing design:

-

available

-

Foudation drawing:

-

available

-

Product name:

-

Tin Ore Processing Plant(Alluvial ore and rock ore)

-

Machines types:

-

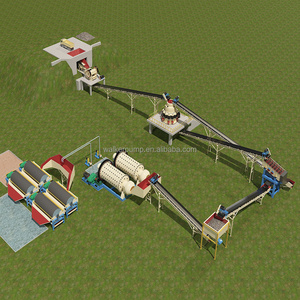

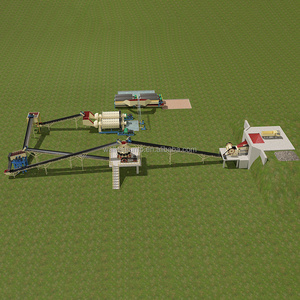

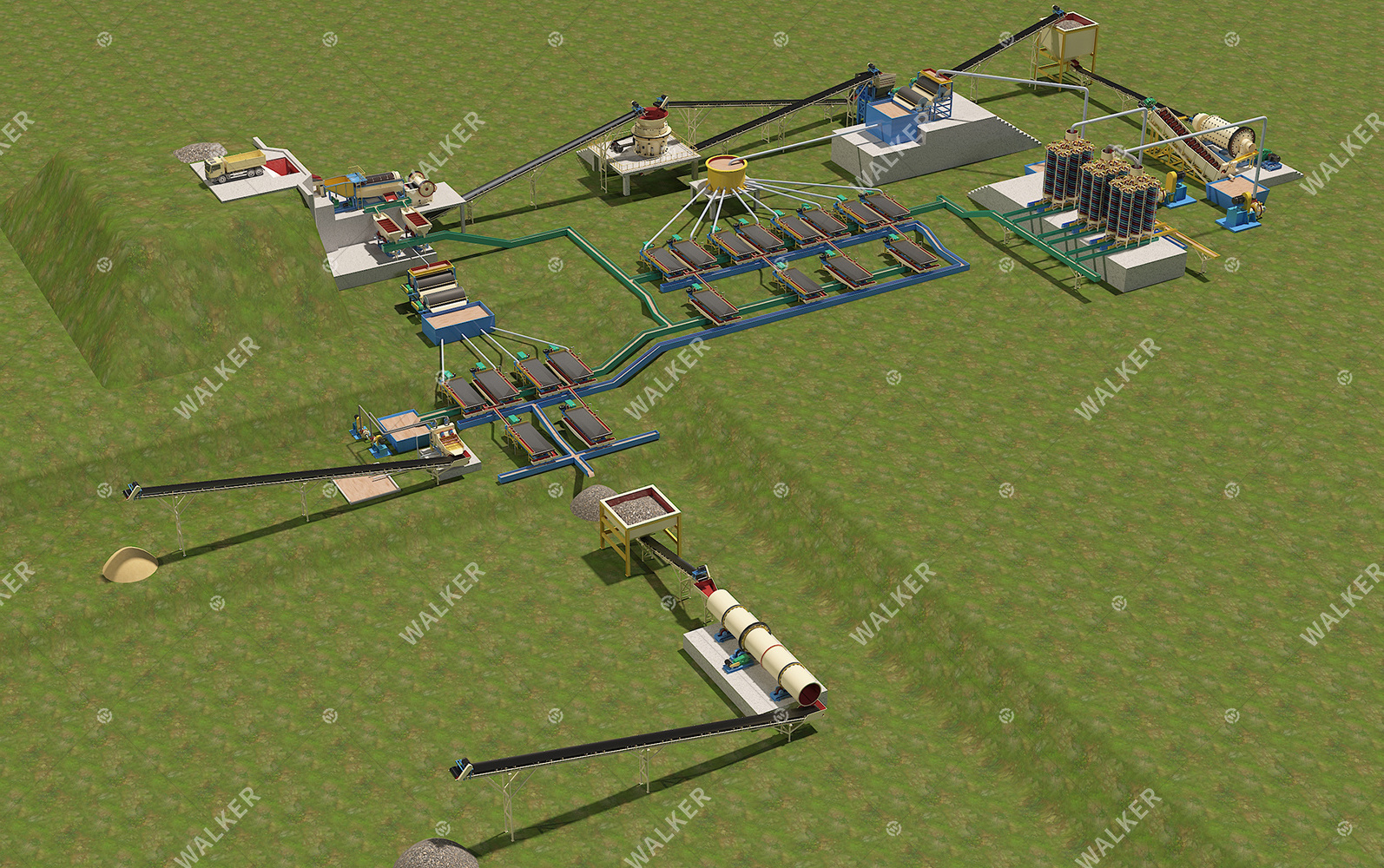

Washing machine, crushing machine, gravity separation machines

-

Capacity:

-

Customizable, no limit

-

Recovery rate:

-

80% to 90% depends on raw ore grade

-

Price:

-

Best factory price

-

Other auxiliary equipment:

-

available

Overview

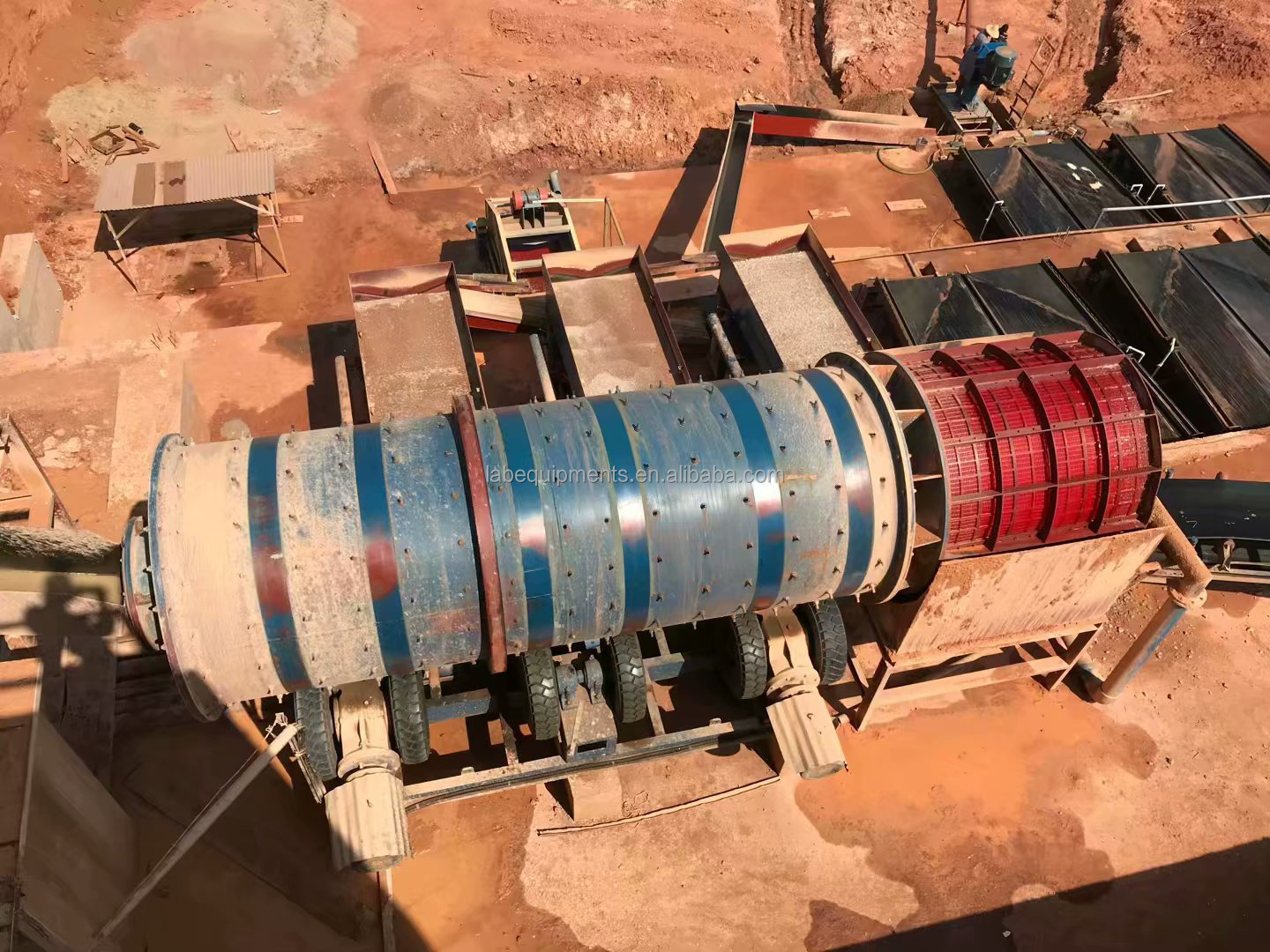

specific gravity difference between tin and waste rock. Due to the large specific gravity difference between tin and waste rock in placer tin ore, a good beneficiation effect can be obtained by using gravity separation methods and equipment. At the same time, it has the advantages of high efficiency, energy-saving and environmental protection, small equipment investment, and low operation cost. It is an ideal choice for placer tin ore beneficiation.

fine-grained tin ore, a shaking table will also be used. The process flow of tin ore gravity separation is screening → jigging → dehydration. For placer tin ore with low monomer dissociation, it often needs to go through two gravity separation processes: screening → jig → rod mill → jig → dehydration. Gravity separation is the most ideal, economical, and effective tin ore dressing method. The sand tin ore gravity separation equipment has a small investment, low operation cost, and no pollution to the environment. The screening gravity separation method is used to treat the sand tin ore in major sand tin washing plants and tin mining ships. The beneficiation effect is good and the application is very common.

100 TPH Alluvial Tin and Rock Tin Process Flowchart Explanation

▼

shaking table for Tin separation. The middlings from the first stage shaking table will go to the second stage shaking table for beneficiation again to improve the recovery rate. The shaking table quantities can adjust based on your mine situation and requirements.

pump for dewatering. After precipitation, the water can be recycled. The overscreen waste can transport away by belt conveyor.

JXSC company have built a 100T/H Ta & Nb ore processing plant in Uganda. We provided “turnkey solution” to our clients in this project. Details include below:

Hopper->Vibrating Feeder->Trommel Scrubber->Jig Separator->(roll crushing mill->)Vibration Screen->Slurry Pump->Shaking Table->Air Dryer->three disc magnetic separator

Not only tin ore, our factory also can make gold ore machine line, chrome ore machine line, tin ore machine line, iron ore machine line, diamond ores machine line and so on.

|

1.Small parts packed in the wooden cases.

|

|

2.Big parts packed by plastic membrane.

|

|

3.The whole big machine is loaded in the container.

|

Jiangxi walker Machinery Co.,Ltd, are a professional manufacturer of complete set mining equipments, a sub-company of JXSC mine machinery factory in Jiangxi province.professional at providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore / Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore, ect. As well as complete set small lab mining machines.

Our core advantages as below:

1.+30years history factory at mining machinery

2.Provide engineer team after sale service

3.Provide complete set mineral processing plant

4.Provide sample testing service in factory lab for free

5.Provide professional ming soolution consulting

*Ore sample testing support

*View our Factory

*Design Flowchart

●Sales service: Send technicians to the site to guide the installation and commissioning, train the operators, and complete the acceptance with you.

●After-sales service: To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

●Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

●How is the quality of your products?

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

●How about the Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

●How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

●How about the service and payment terms?

Answer: We can accept T/T or other payment ways you request; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.