- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

mold repair welding

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Target material:

-

large mould/mod

-

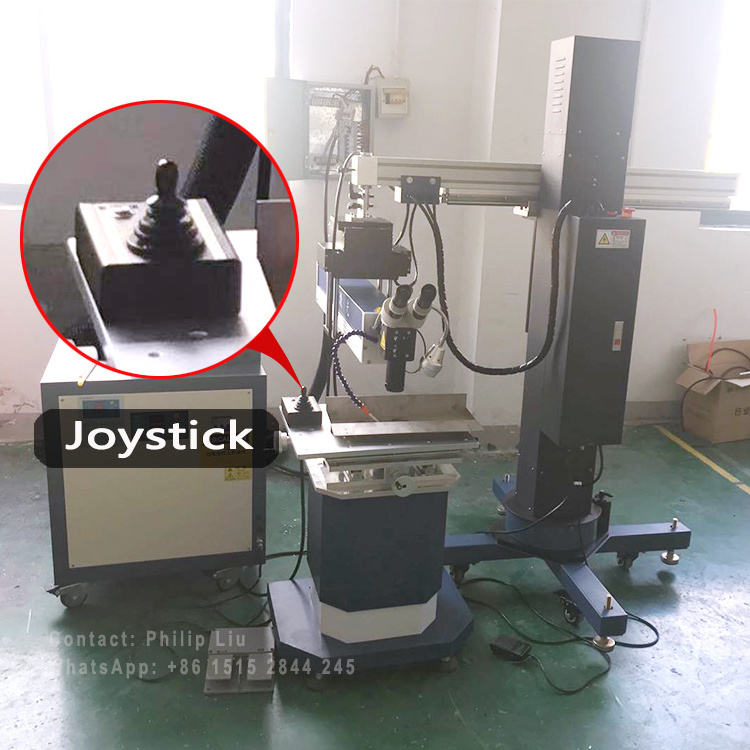

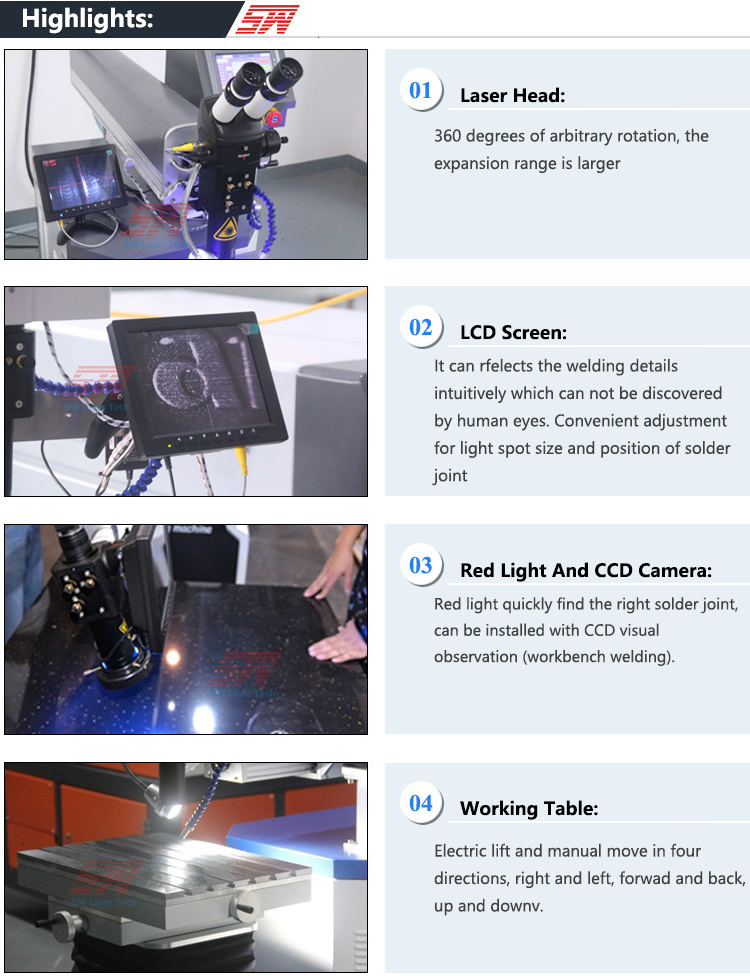

Observing System:

-

CCD

-

Welding depth:

-

0~3mm

-

Cooling System:

-

Water Cooling

-

Pulse Frequency::

-

0-100Hz

-

Power supply:

-

380V/3-phase/50Hz (customized)

-

keywords:

-

mould laser welding machine

-

Laser type:

-

YAG

Quick Details

-

Place of Origin:

-

China

-

Dimensions:

-

600*1200*1200MM

-

Weight (KG):

-

250 KG

-

Product name:

-

mold repair welding

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Target material:

-

large mould/mod

-

Observing System:

-

CCD

-

Welding depth:

-

0~3mm

-

Cooling System:

-

Water Cooling

-

Pulse Frequency::

-

0-100Hz

-

Power supply:

-

380V/3-phase/50Hz (customized)

-

keywords:

-

mould laser welding machine

-

Laser type:

-

YAG

mold repair welding

|

mold repair welding

|

||

| No | Model | SWLASER-MJ200 |

| 1 | max laser power | 200W/300W/400W |

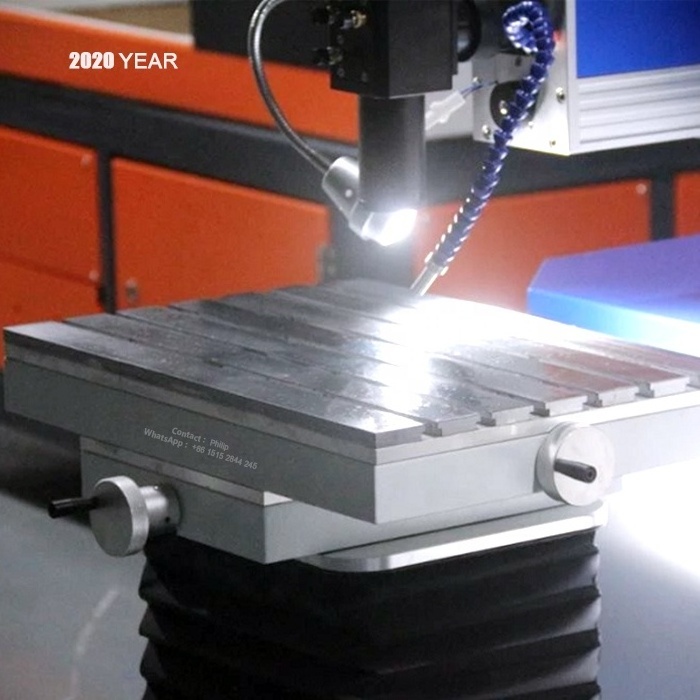

| 2 | laser wavelength | 1064nm |

| 3 | welding depth | 0~3mm |

| 4 | pulse width | 0-20ms |

| 5 | Laser frequency | 0-50HZ |

| 6 |

Laser spot adjust range |

0.2mm-3.0mm (optional) |

| 7 |

Laser type |

ND:YAG |

| 8 | Spot size | 0.2-3.0mm |

| 9 | positioning system | microscope |

| 10 | Cooling method | Water c ±0.02mmooling |

| 11 | machine power consumption power | ≤10KW |

| 12 | Power supply | 380V 50Hz/60Hz |

Application Materials:

mould repair laser welding machine

can be widely used in many fields, such as as mold laser welding machine widely used in molds, precision injection molding, die casting and punching mold, stainless steel products and other hard materials cracks, chipping, grinding and wear seal repair, welding, cell phones, jewelry, electronics, sensors, precision machinery, communications, crafts and other industries.

| 1. | Packing Method: |

PET wrapping film + shake proof foamed rubber + fumigation-free polywood case + Pet belt |

| 2. | Laser Welder Dimension: | 600*1200*1200mm |

| Chiller Dimension | 560 × 800 × 400mm | |

| 3. | Gross Weight: | 267kg |

Kunshan SW laser Technology Co., Ltd

is established in 2002 in Shanghai City, engaging in the development, design, and manufacture of

laser marking machine

,

laser welding machine

, and

laser cutting machine

, etc. We invested 30,000,000 RMB in the new manufacture base in Kunshan City in 2017. Our new plant has come into service, with 318 sets of machines per month. And the annual turnover reachs over 102,000,000 RMB.

Moreover, our facotry is very near from the Shanghai Pudong International airport, only 15 minutes by the high-speed train.And it taks 2 honurs to reach the Shanghai Sea Port, very convenient for delivering the machines to all over ther world.

Q: What is the packing?

A:

we have three layers of packing: the outer layer is made of plywood and will not be fumigated.Cover the middle with a thick sponge to prevent the machine from shaking.Lined with plastic wrap, waterproof.

Q: Will the packing be damaged in transit?

A:

our packing takes all the factors of damage into consideration to ensure the safety of the packing. Our freight forwarder has rich experience in safe transportation.

Q: how do I install and run the machine?

A:

our engineers have installed and tested the machine before shipment.No components need to be installed.

For laser welding machine, we have menu and video to show you the training.We will also train you online.This is how most customers train their machines to run. Few customers come to the factory for training.

Q;What should I do if the machine breaks down?

A:

if you encounter such A problem, please contact us as soon as possible and don't try to repair the machine by yourself or others.We will solve it for you as soon as possible within 24 hours.