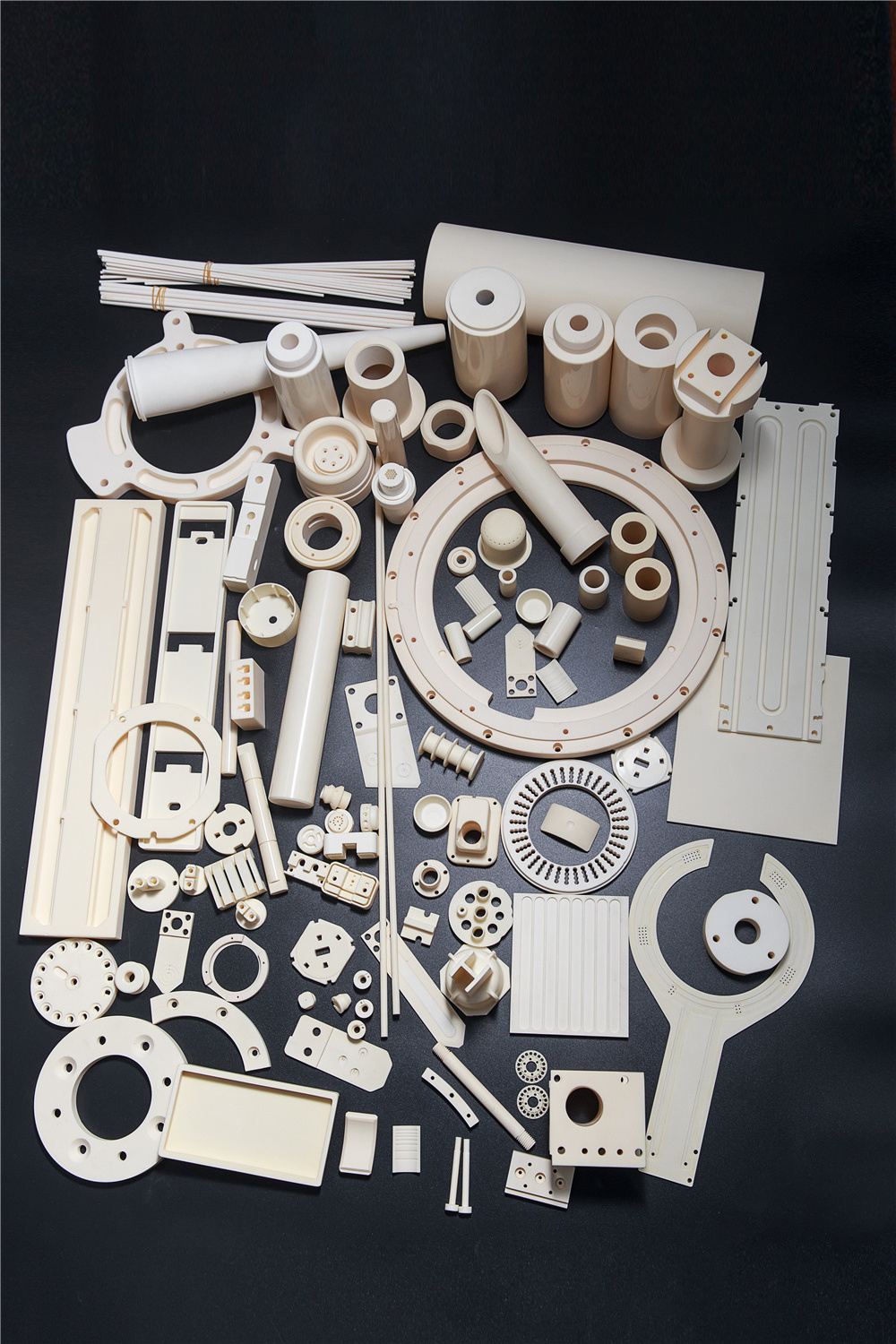

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

xdl

-

Color:

-

White

-

Product name:

-

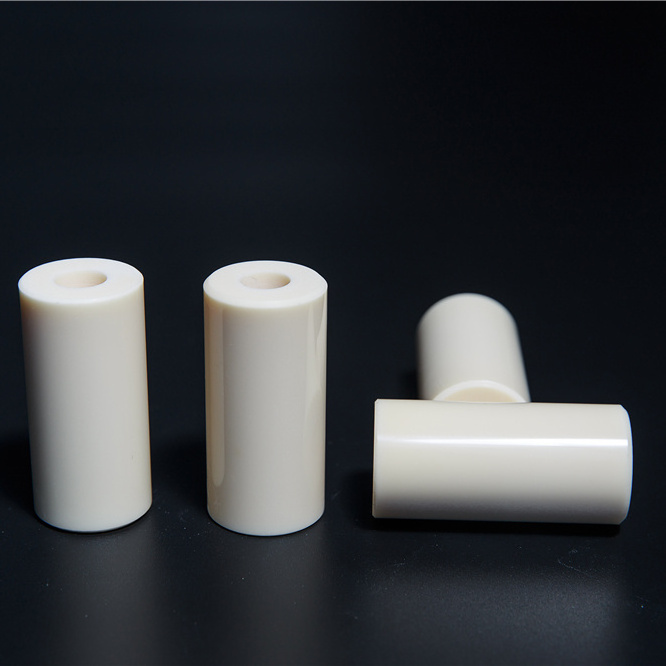

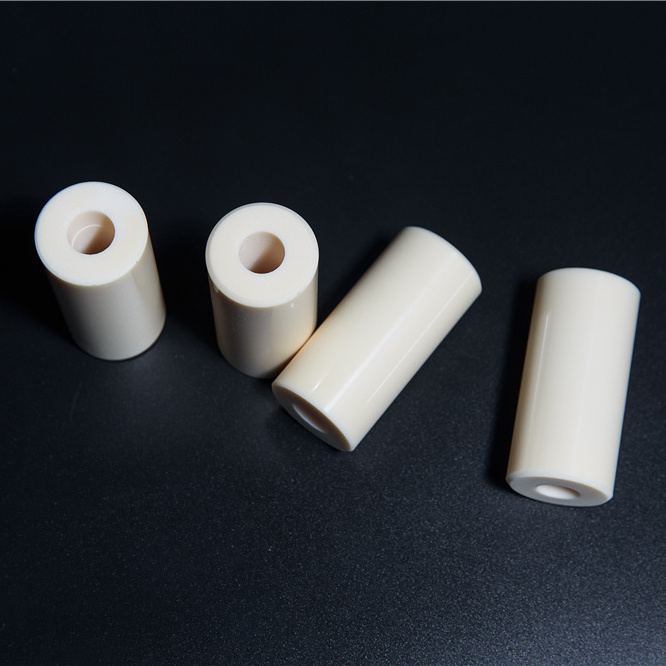

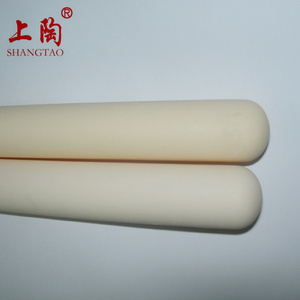

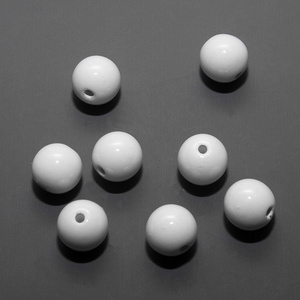

alumina ceramic parts

-

Item:

-

Alumina Ceramic parts

-

type:

-

Metallized Ceramic parts

-

Usage:

-

Industry Usage

-

Keywords:

-

Al2o3 alumina ceramic parts

-

Advantage:

-

wear-resisting/High temperature resistance

-

MOQ:

-

1-10pcs

-

Size:

-

all size

-

Feature:

-

High Hardness

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

China

-

Model Number:

-

xdl/7

-

Brand Name:

-

xdl

-

Color:

-

White

-

Product name:

-

alumina ceramic parts

-

Item:

-

Alumina Ceramic parts

-

type:

-

Metallized Ceramic parts

-

Usage:

-

Industry Usage

-

Keywords:

-

Al2o3 alumina ceramic parts

-

Advantage:

-

wear-resisting/High temperature resistance

-

MOQ:

-

1-10pcs

-

Size:

-

all size

-

Feature:

-

High Hardness

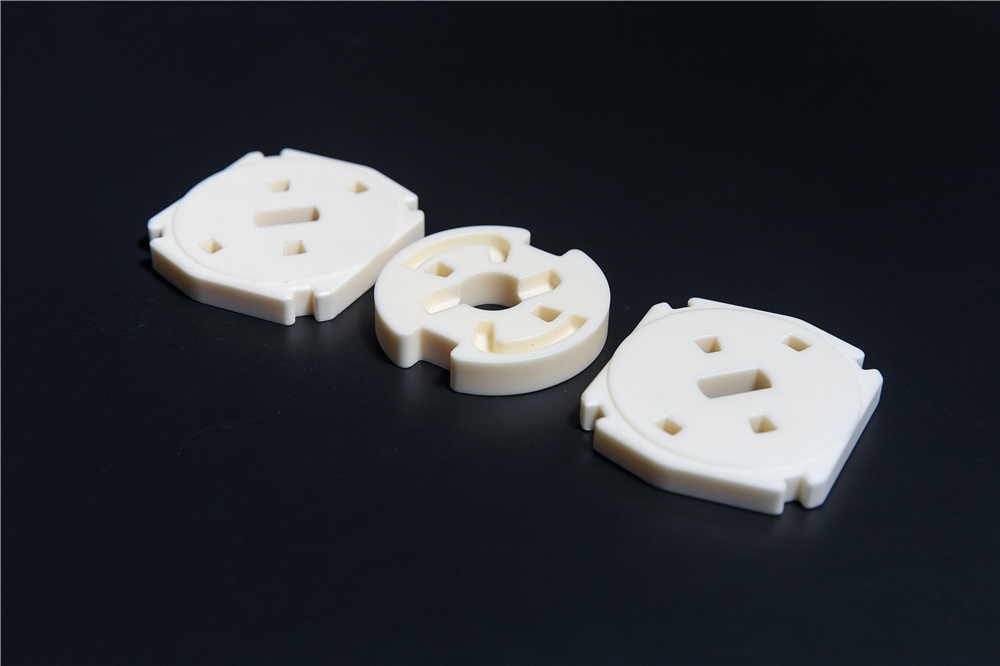

Products Description

Features:

1.Excellent electrical insulation

2.Relatively low strength and fracture toughness

3.Resistance to wear and corrosive

4.Excellent thermal stability

5.Resistance to high temperatures

6.High electrical resistivity

7.Good chemical stability

8.High corrosion resistance

9. A variety of specifications available.

10.Satisfy various technical request

|

Dimensional accuracy

|

Up to 0.01mm

|

|

|

Smoothness

|

Highest possible mirror

|

|

|

Concentricity

|

Up to 0.01mm

|

|

|

Parallelism

|

Up to 0.01mm

|

|

|

The inner hole tolerance

|

The minimum 0.01mm

|

|

|

Straight flute

|

The narrowest 0.1x100mm

|

|

|

The thickness of the size

|

Minimum to 0.2mm

|

|

|

The screw thread

|

Minimum internal thread M2

|

|

|

Cylindricity

|

Up to 0.01mm

|

|

|

The linear tolerance

|

Up to 0.01mm

|

|

|

The smallest aperture

|

The minimum 0.07mm

|

|

|

Precision process

|

CNC maching,grinding,lapping

|

|

|

Surface finish

|

Glazed,polishing or metallized

|

|

|

Visual quality:

1. No cracks, no dark dots, no contamination and sharp edges; 2. Evenly distributed glaze with very smooth surface |

|

|

Technical Parameters

Alumina ceramic parts

Alumina ceramic parts are made of aluminum oxide ceramics. Alumina is a ceramic material with high thermal conductivity, compressive strength, and thermal shock resistance. It also has a low thermal expansion, making it a suitable material for furnace use in the crucible, tube, and thermo couple sheath form. Aluminum oxide is high hardness and good wear resistance, making it a suitable material for ball valves, piston pumps, and deep drawing tools. In addition, alumina ceramic parts can be easily combined with metals and other ceramic materials using brazing techniques and metallization.

|

Property

|

Units

|

|

|

|

|

|||

|

Al2O3 Content

|

%

|

96

|

98

|

99.5

|

99.7

|

|||

|

Density

|

g / cm3

|

3.70

|

3.80

|

3.90

|

3.92

|

|||

|

Color

|

-

|

White

|

White

|

Ivory

|

Ivory

|

|||

|

Compressive Strength @ 25 C

|

Mpa

|

2229

|

2091

|

2512

|

2350

|

|||

|

Tensile Strength @ 25 C

|

MPa

|

200

|

200

|

248

|

252

|

|||

|

Flexural Strength @ 25 C

|

MPa

|

331

|

276

|

324

|

320

|

|||

|

Elastic Modulus @ 25 C

|

GPa

|

290

|

331

|

366

|

380

|

|||

|

Hardness : Knoop Rockwell

|

(Gpa) Kg/mm2

R45N |

(11.7) 1196

79 |

(12.5) 1276

77 |

(14) 1428

85 |

(15) 1510 90

|

|||

|

Thermal Conductivity @ 25 C

|

W / m-Deg K

|

20.8

|

28.1

|

30.7 |

31.6

|

|||

|

Coefficient of Thermal Expansion @ 25-1000 C

|

1 X 10-6 /

Deg C |

7.9

|

8.5

|

8.1

|

8.0

|

|||

|

Specific Heat @ 25 C

|

cal / g / Deg C

|

.184

|

.184

|

.182

|

.180

|

|||

|

Maximum Working Temp.

|

Deg C

|

1650

|

1650

|

1700

|

1700

|

|||

|

VolumeResitivity @25C @700 C

|

ohm-cm

ohm-cm |

1 X 10-13

1 X 10-8 |

1X 10-13

2.2 X 10-9 |

1 X 10-13

6 x 10-7 |

1 X 10-13

6 x 10-7 |

|||

|

Dielectric Strength

(@Thickness) 100Mils |

ac volts

per mil |

350

|

340 |

335

|

330

|

|||

|

Dielectric Constant 1Mhz

@25C |

e' / eo

|

8.6

|

9.4

|

9.7

|

10.0

|

|||

|

Dissipation Factor 1 Mhz

@25C |

Tan Delta

|

.0004

|

.0003

|

.0003

|

.0002

|

|||

Hot Searches