- Product Details

- {{item.text}}

Quick Details

-

Type:

-

Undercarriage Parts

-

Part Name:

-

Excavator Idler, Front Idler, Idler Assy, Idler Group

-

Material:

-

50Mn/40MnB

-

Finish:

-

Smooth

-

Technique:

-

Forging casting

-

Surface Hardness:

-

HRC50-56,depth:4mm-10mm

-

Color:

-

Black or Yellow

-

Certification:

-

ISO9001-9002

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

LONEPO/OEM/ODM

-

Application:

-

Crawler Excavator,Bulldozer,Crane,Loader

-

Type:

-

Undercarriage Parts

-

Part Name:

-

Excavator Idler, Front Idler, Idler Assy, Idler Group

-

Material:

-

50Mn/40MnB

-

Finish:

-

Smooth

-

Technique:

-

Forging casting

-

Surface Hardness:

-

HRC50-56,depth:4mm-10mm

-

Color:

-

Black or Yellow

-

Certification:

-

ISO9001-9002

Mini excavator idler ex15 front idler undercarriage parts 9134478 9312918 for hitachi

The idler, which is also called idler group, idler assy, front idler or idler wheel, is one part of undercarriage parts for crawler heavy equipments such as excavator, bulldozer, crane, drilling machine etc.

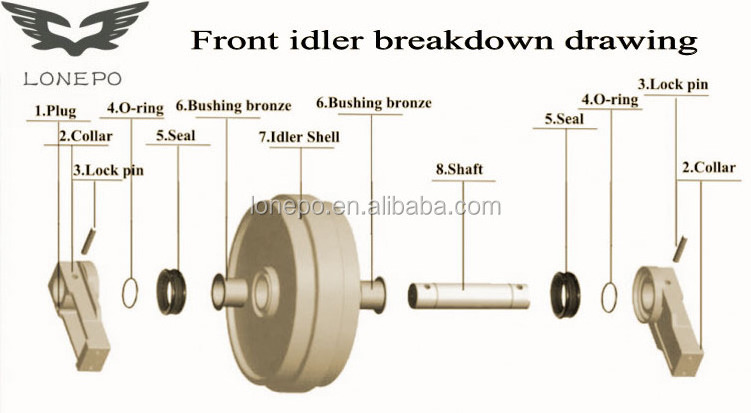

The idler is made of idler shell, shaft, brackets, Bi-metallic Bearings and seal group. It is made by casting or forging, machining, heat treatment, assembly, painting etc.

The quality and working life depends on the quality of raw steels, the hardness of rail surface, the depth of hardness layer, the quality of seal group etc.

| Material |

50Mn/40MnB |

| Finish | Smooth |

| Technique | Casting/Forging |

| Surface Hardness | HRC50-56 , Depth:4mm-10mm |

| Colors | Black or Yellow |

| Warranty Time | 2000 Hours ( Normal life 4000 hours) |

| Certification | IS09001-9001 |

| MOQ | 2 Pieces |

| FOB Price | FOB Xiamen US$ 20-200/Piece |

| Delivery Time | Within 30 days after contract established |

| Payment Term | T/T,L/C,WESTERN UNION |

| OEM/ODM | Acceptable |

Click Here To View More Product Categories

Track Roller Carrier Roller Sprocket/Segment Front Idler Track Link Track Shoe

Track Adjuster Assembly Bucket Bucket Teeth Bucket Link Pins and Bushings

Bolt and Nut Hydraulic Cylinder Slewing Bearing Hydraulic Pump

Main Features:

1.Idler is through quench-tempering processes to guarantee excellent mechanical properties, high strength and superior wear resistence to bending and breakage.

2.Surface hardness of idler is HRC50-60 for reduced wear and longer life, adding value to your products further to your business by maximizing durability of your products.

3. Idler have precise design, carefully manufactured for proper fix easy grousering heavy loaded capacity up to 50tons without compromising proper functioning of the excavators reliable quality, high cost performance,quality services.Our products,your best choice.

| THE MODELS FOR EXCAVATOR/BULLDOZER | ||||||||

| FOR HITACHI | ||||||||

| EX40-1 | EX40-2 | EX55 | EX60 | EX60-2 | EX60-3 | EX60-5 | EX70 | EX75 |

| EX100 | EX110 | EX120 | EX120-1 | EX120-2 | EX120-3 | EX120-5 | EX130-1 | EX200-1 |

| EX200-2 | EX200-3 | EX200-5 | EX220-3 | EX220-5 | EX270 | EX300 | EX300-1 | EX300-2 |

| EX300-3 | EX300-5 | EX300A | EX330 | EX370 | EX400-1 | EX400-2 | EX400-3 | EX400-5 |

| EX450 | ZAX30 | ZAX55 | ZAX200 | ZAX200-2 | ZAX330 | ZAX450-1 | ZAX450-3 | ZAX450-5 |

| FOR KOMATSU | ||||||||

| PC20-7 | PC30 | PC30-3 | PC30-5 | PC30-6 | PC40-7 | PC45 | PC45-2 | PC55 |

| PC120-6 | PC130 | PC130-7 | PC200 | PC200-1 | PC200-3 | PC200-5 | PC200-6 | PC200-7 |

| PC200-8 | PC210-6 | PC220-1 | PC220-3 | PC220-6 | PC220-7 | PC220-8 | PC270-7 | PC202B |

| PC220LC-6 | PC220LC-8 | PC240 | PC300 | PC300-3 | PC300-5 | PC300-6 | PC300-7 | PC300-7K |

| PC300LC-7 | PC350-6/7 | PC400 | PC400-3 | PC400-5 | PC400-6 | PC400lc-7 | PC450-6 | PC450-7 |

| PC600 | PC650 | PC750 | PC800 | PC1100 | PC1250 | PC2000 | ||

| D20 | D31 | D50 | D60 | D61 | D61PX | D65A | D65P | D64P-12 |

| D80 | D85 | D155 | D275 | D355 | ||||

| FOR CATERPILLAR | ||||||||

| E200B | E200-5 | E320D | E215 | E320DL | E324D | E324DL | E329DL | E300L |

| E320S | E320 | E320DL | E240 | E120-1 | E311 | E312B | E320BL | E345 |

| E324 | E140 | E300B | E330C | E120 | E70 | E322C | E322B | E325 |

| E325L | E330 | E450 | CAT225 | CAT312B | CAT315 | CAT320 | CAT320C | CAT320BL |

| CAT330 | CAT322 | CAT245 | CAT325 | CAT320L | CAT973 | |||

| D3 | D3C | D4 | D4D | D4H | D5M | D5H | D6 | D6D |

| D6M | D6R | D6T | D7 | D7H | D7R | D8 | D8N | D8R |

| D9R | D9N | D9G | D10 | |||||

| FOR KOBELCO | ||||||||

| SK120-6 | SK120-5 | SK210-8 | SK210LC-8 | SK220 | SK220-1 | SK220-3 | SK220-5/6 | SK200 |

| SK200 | SK200 | SK200-3 | SK200-6 | SK200-8 | SK200-5/6 | SK60 | SK290 | SK100 |

| SK230 | SK250 | SK250-8 | SK260LC-8 | SK300 | SK300-2 | SK300-4 | SK310 | SK320 |

| SK330-8 | SK330 | SK350LC-8 | SK235SR | SK450 | SK480 | SK30-6 | ||

| FOR SUMITOMO | ||||||||

| SH120 | SH120-3 | SH200 | SH210-5 | SH200 | SH220-3 | SH220-5/7 | SH290-3 | SH350-5/7 |

| SH220 | SH280 | SH290-7 | SH260 | SH300 | SH300-3 | SH300-5 | SH350 | SH60 |

| FOR VOLVO | ||||||||

| EC160C | EC160D | EC180B | EC180C | EC180D | EC210 | EC210 | EC210B | EC240B |

| EC290 | EC290B | EC240 | EC55 | EC360 | EC360B | EC380D | EC460 | EC460B |

| EC460C | EC700 | EC140 | EC140B | EC160B | ||||