- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanxi, China

-

Weight:

-

50

-

Product name:

-

Hot vulcanizing press Machine

-

Usage:

-

rubber belt splicing and repair

-

Vulcanizing pressure:

-

1-2Mpa

-

Vulcanizing temperature:

-

145℃

-

Cooling system:

-

Water Cooling System

-

Heating-up time:

-

30 mins

-

Timing adjustment range:

-

0-99min

-

Temperature adjustment range:

-

0-200℃

-

OEM:

-

Availalbe

-

Certification:

-

ISO9001, ISO14001, ISO45001

Quick Details

-

Warranty:

-

1 Year

-

Displacement:

-

Other

-

Pump Type:

-

antomatic pump

-

Place of Origin:

-

Shanxi, China

-

Weight:

-

50

-

Product name:

-

Hot vulcanizing press Machine

-

Usage:

-

rubber belt splicing and repair

-

Vulcanizing pressure:

-

1-2Mpa

-

Vulcanizing temperature:

-

145℃

-

Cooling system:

-

Water Cooling System

-

Heating-up time:

-

30 mins

-

Timing adjustment range:

-

0-99min

-

Temperature adjustment range:

-

0-200℃

-

OEM:

-

Availalbe

-

Certification:

-

ISO9001, ISO14001, ISO45001

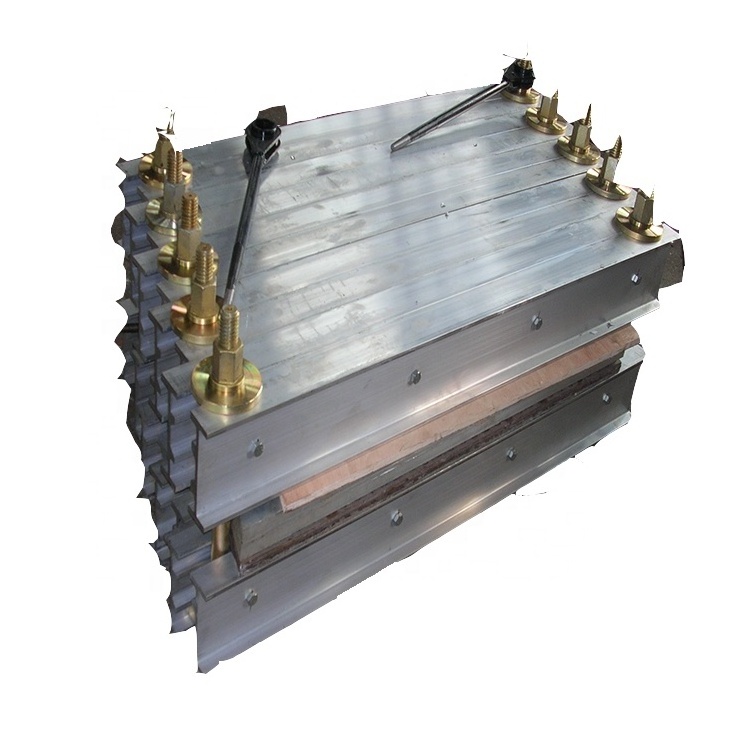

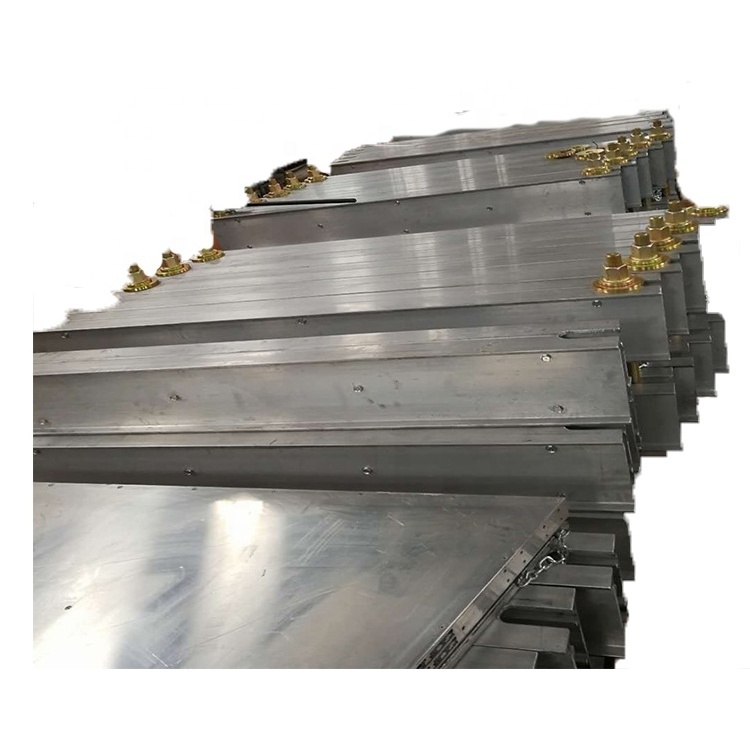

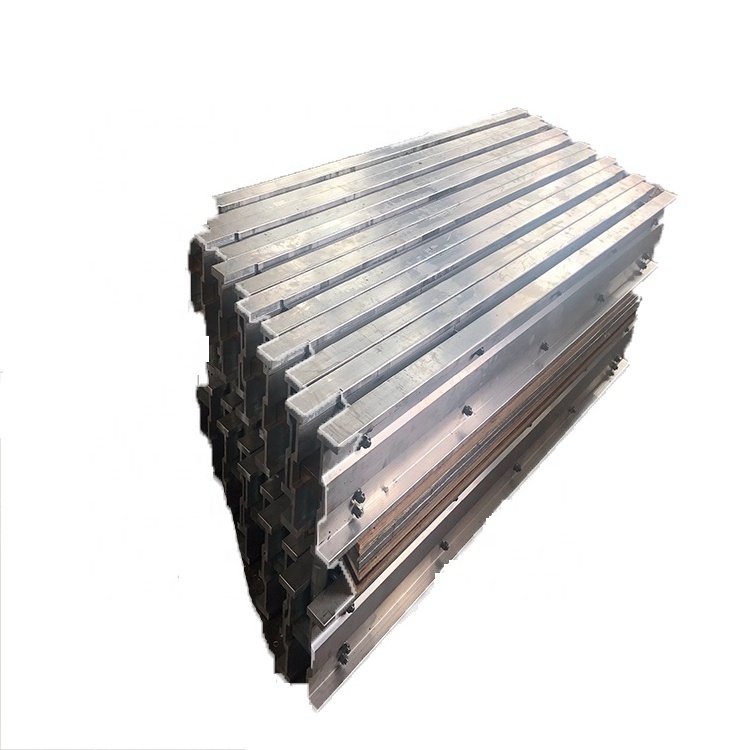

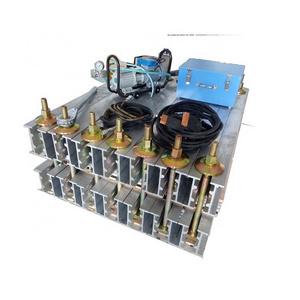

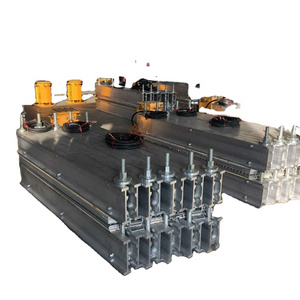

Conveyor belt vulcanizing joint cure machine press is for conveyor belt hot vulcanizing joint, widely used in the field of jointing of canvas, nylon, steel cord convey o r belt at spot in metallurgy, mining, power plants, ports, building materials, chemical industry, etc.

Features :

1.The electric control box of hot splicing press is made of industrial grade aluminum alloy,small volume and light weight. Three-phase source of power supply.

2.Water press system can supply stable press.

3.Fast heating, steady heating temperature.

4.Equip p ed with auto electric control,easy to operate.

5. Degree of the heating platen: 22°/17°/ 20° (rectangle and other degree is optional)

6.High pressure water pump, adopted three cylinder plunger pump driven by single-phase machine,with the characteristics of compact structure, small volume, reliable, maintenance friendly.

7.Sturdy heating plate with hydraulic pressure system ensures temperature unifor-

mity, high pressure can reach Max.2.0 MPa ;Heating plate including air or water cooling.

8.

Time of heat preservation for vulcanizing could be adjusted according to thickness of the rubber belts;

9.

Splicing length of rubber conveyor belt for vulcanizing jointing could be connected together by single or several pieces if necessary;

10.R

ubber conveyor belt as well as tension in kilogram required for vulcanizing jointing when ordering products.

11

.

Users could order spare electric pumps additionally according to requirements.

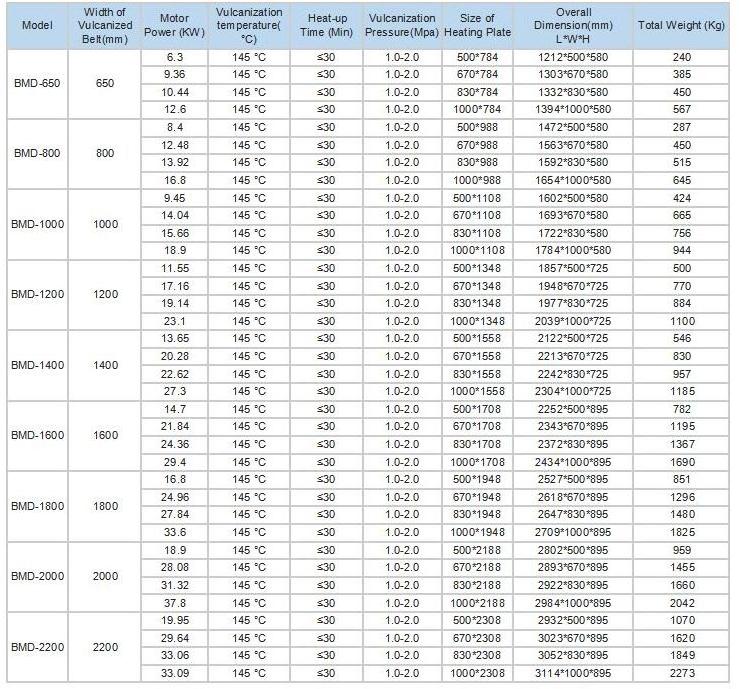

Model for Choice( or Just me your belt size, belt type)

12.Customization/OEM:Different heating platen size and combination

Technical S pecification:

1. Vulcanization pressure: 1.0-2.0Mpa or customized;

2. Vulcanization temperature: 145 °C;

3. S urface temperature d ifference of vulcanized plate: ± 3 °C;

4. Heating-up time (145 °C): ≤30 mins;

5. Power supply voltage: 220V to 114 0 V ; 50/60 Hz; 3Ph;

6. Output power of Electronic Control Box: 36 KW;

7. Temperature adjustment range: 0 - 200 °C;

8. Timing adjustment range: 0 - 99 min;

9. After the pressurization of 0.8 MPa, the gap between upper and lower heating plate is not more than 0.4 mm.

Technical Parameters

Main components

1. Aluminum Frame (Spanner Bars):High quality aluminum, designed for any belt width or operating pressure

2. High tensile steel bolt and nut assemblies, recessed in the bar.

3. Lightweight aluminum platens within new rapid cooling system

4.New electric connect system (Old flat plug & socket design: plug pins broken easily)

Packing