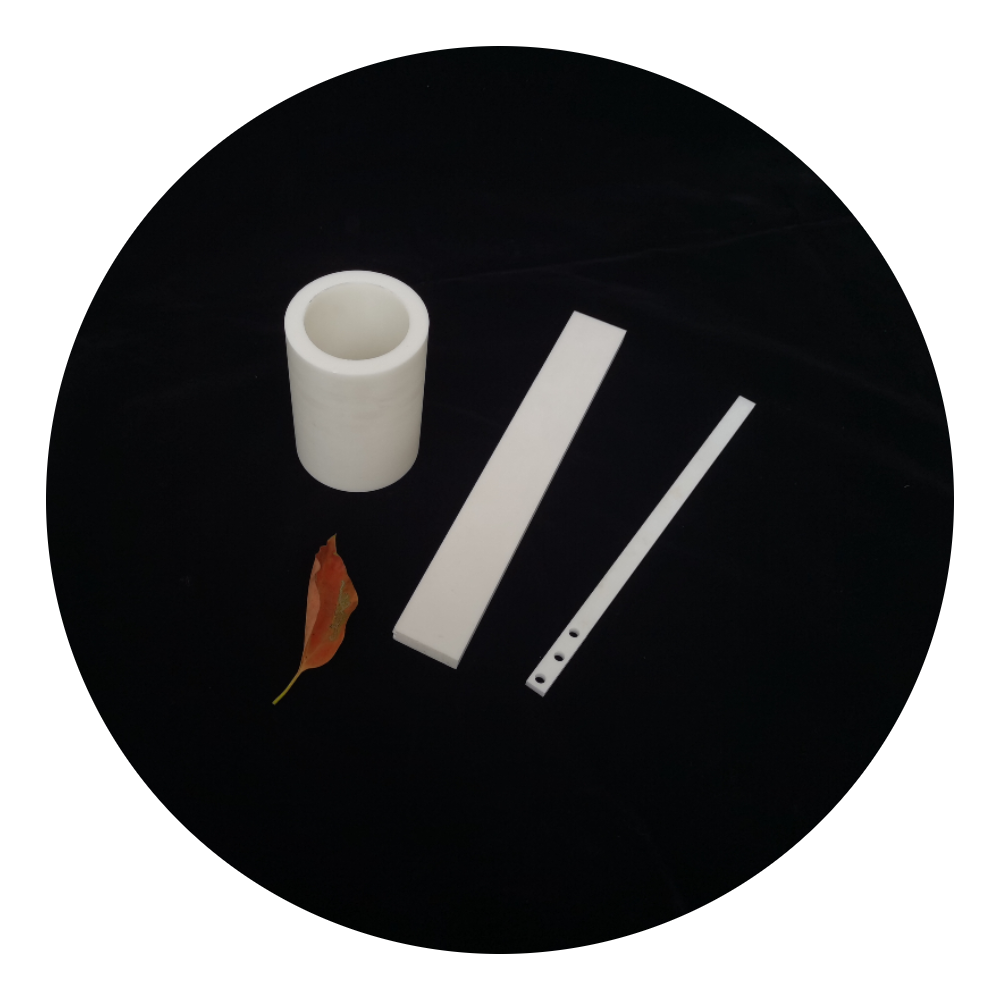

The hardness and strength of zirconia ceramics make them an ideal material for several applications. They can be found in prosthetic materials for dentistry and bone replacements and as ideal materials for automobiles and high altitude aircraft. The diverse uses of zirconia ceramics have made them a viable and useful material for engineers in creating new and unique designs and functions.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Winner

-

Shape:

-

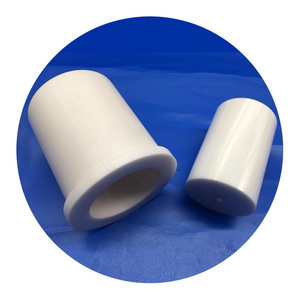

Tubular

-

Usage:

-

Industry Usage

-

Size:

-

Customers' Requests

-

Feature:

-

High Hardness

-

Advantage:

-

Professional Technical Support

-

Item:

-

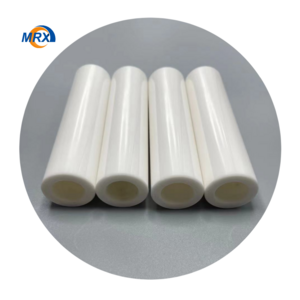

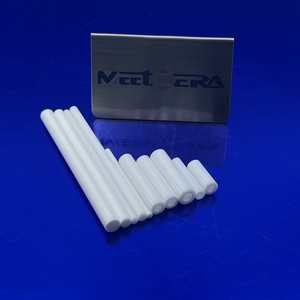

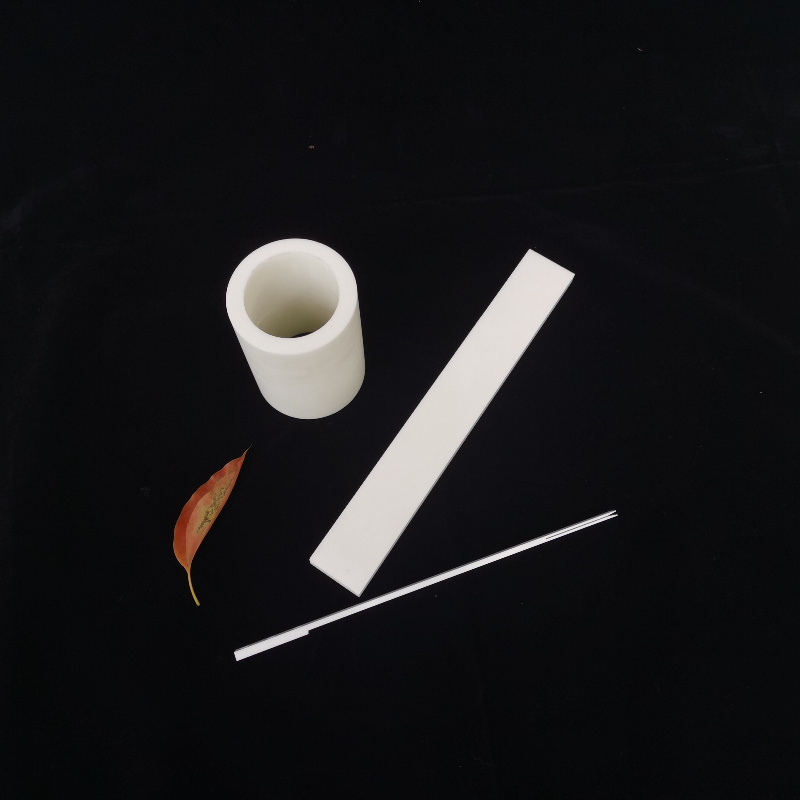

Zirconia Ceramic Parts

-

MOQ:

-

1-10Pcs

Quick Details

-

Material:

-

Zirconia Ceramic

-

Place of Origin:

-

Jiangsu, China

-

Model Number:

-

Zr-1

-

Brand Name:

-

Winner

-

Shape:

-

Tubular

-

Usage:

-

Industry Usage

-

Size:

-

Customers' Requests

-

Feature:

-

High Hardness

-

Advantage:

-

Professional Technical Support

-

Item:

-

Zirconia Ceramic Parts

-

MOQ:

-

1-10Pcs

Zirconia ceramic

Zirconia Ceramics, or zirconium dioxide ceramics, are exceptionally strong technical ceramic materials with excellent hardness, toughness, and corrosion resistance without the brittleness common to other ceramic materials. There are several grades of zirconia ceramics, with yttria and magnesia partially stabilized zirconia ceramics being the most common.

|

Product Name

|

Machining Ceramic

|

|

|

|

|

|

|

|

|||||||

|

Material

|

Aluminum , zirconia, silicon nitride, boron nitride, silicon carbide

|

|

|

|

|

|

|

|

|||||||

|

Length

|

10mm - 1000mm

|

|

|

|

|

|

|

|

|||||||

|

Size

|

According to drawings or samples

|

|

|

|

|

|

|

|

|||||||

|

Torlerance

|

+/- 0.01mm

|

|

|

|

|

|

|

|

|||||||

|

Surface Roughness

|

Ra 0.05

|

|

|

|

|

|

|

|

|||||||

|

Shipping

|

Air Express (DHL/UPS/TNT/ FedEx)

|

|

|

|

|

|

|

|

|||||||

|

Lead time

|

10 - 30 days

|

|

|

|

|

|

|

|

|||||||

|

Properties

|

Units

|

Steatite Ceramic

|

Cordierite Ceramic

|

Mullite Ceramic

|

95% Al₂O₃

|

99% Al₂O₃

|

Zirconia Ceramic

|

Silicon Nitride

|

|

Colour

|

|

White

|

Yellow

|

White

|

White

|

Ivory

|

White

|

Grey

|

|

Density

|

g/cm3

|

2.7

|

1.9

|

2.6

|

3.5

|

3.85

|

6

|

3.2

|

|

Flexural Strength

|

Mpa

|

140

|

30

|

120

|

280

|

340

|

1150

|

600

|

|

Compressive Strength

|

MPa

|

900

|

350

|

500

|

2100

|

2200

|

2500

|

2500

|

|

Max Use Temperature

|

°C

|

1000

|

1200

|

1300

|

1400

|

1650

|

1500

|

1800

|

|

Thermal Condutivity

|

W(m.K)

|

2~3

|

1.3~1.8

|

2~6

|

16~28

|

19~30

|

2.5

|

20

|

|

Thermal Expansion Cofficient

|

10^-6/°C

|

7 ~ 9

|

1.5~3.5

|

5~6

|

6.5~7.5

|

6~8

|

8~10

|

3~4

|

|

ThermalShock Resistance

|

△TC

|

100

|

300

|

150

|

140

|

150

|

250

|

600

|

|

Specific Heat

|

J/kg.K

|

850

|

800

|

900

|

950

|

950

|

500

|

500

|

|

Dielectric Strength

|

KV/mm

|

20

|

—

|

30

|

12

|

10

|

5

|

20

|

|

Dielectric Constant

|

Er

|

6

|

—

|

8

|

9

|

9

|

12

|

6

|

Hot Searches