- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

5000kgs

-

Size:

-

5-50m3

-

Power:

-

1.1-22kw

-

Weight (KG):

-

5000 kg

-

Product name:

-

package domestic mbbr biomedia for marine sewage treatment plant

-

Application:

-

wastewater treatment

-

Function:

-

degrade cod and bod

-

Certification:

-

ISO9001:2008

-

Color:

-

Black

-

Paint:

-

Epoxy paint and anti-corrosion

-

Service life:

-

50 years

-

Opearation grade:

-

Full automatic

-

Working place:

-

Any place

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

XRD

-

Material:

-

Insulation layer, Stainless Steel or Glass fibre reinforced plastics

-

Weight:

-

5000kgs

-

Size:

-

5-50m3

-

Power:

-

1.1-22kw

-

Weight (KG):

-

5000 kg

-

Product name:

-

package domestic mbbr biomedia for marine sewage treatment plant

-

Application:

-

wastewater treatment

-

Function:

-

degrade cod and bod

-

Certification:

-

ISO9001:2008

-

Color:

-

Black

-

Paint:

-

Epoxy paint and anti-corrosion

-

Service life:

-

50 years

-

Opearation grade:

-

Full automatic

-

Working place:

-

Any place

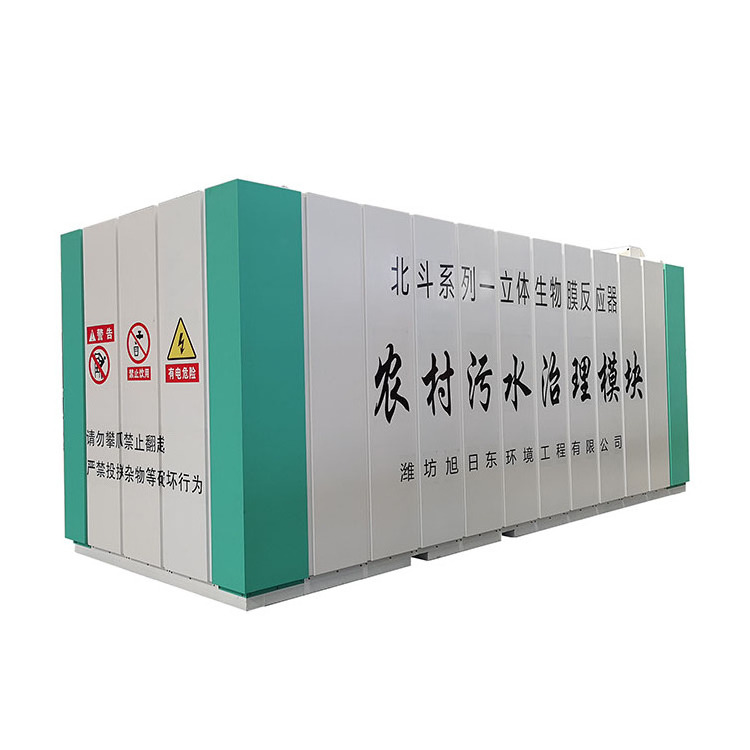

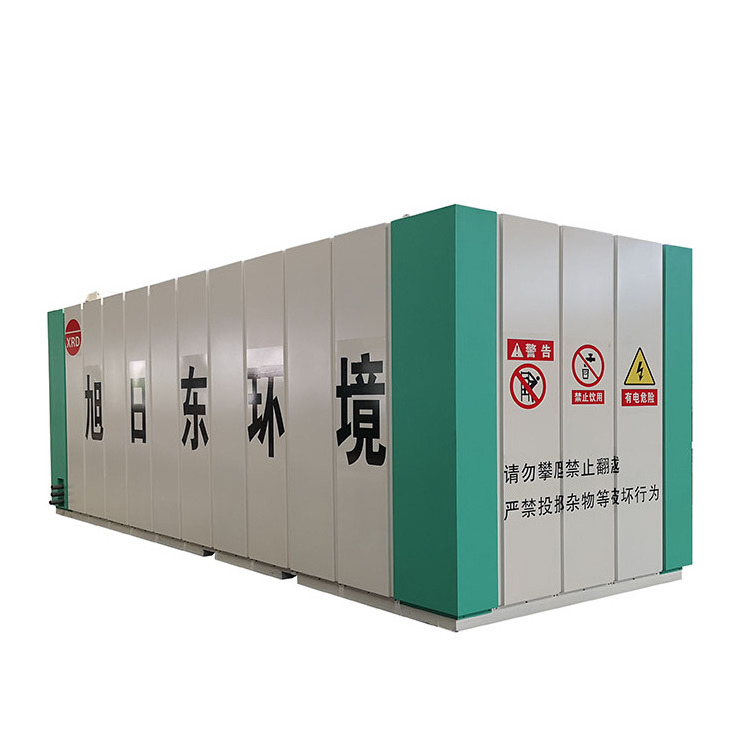

package domestic mbbr biomedia for marine sewage treatment plant

Function & application

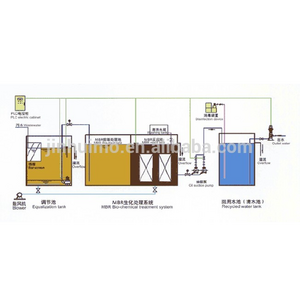

Our company adopts "A3/O+MBBR integration technology", which combines the A3/O process of strengthening nitrogen and phosphorus removal with MBBR to completely solve the problems that water, nitrogen and phosphorus can not reach the standard.

MBBR is the abbreviation of Moving Bed Biofilm Reactor. It has the advantages of both traditional fluidized bed and biological contact oxidation. It has stable and reliable operation, strong impact load resistance and good denitrification effect. It is a cost-effective sewage treatment process.

Applications:

1.Sewage wastewater treatment

2.Municipal and commercial biological waste water

3.Livestock wastewater

4.Organic wastewater

Feature & advantage

1. Set the pre-deNOx unit to effectively enhance the effect of nitrogen and phosphorus removal, the ammonia nitrogen removal rate is over 95%, and the total phosphorus removal rate is over 96%;

2. Aeration return device saves system energy consumption;

3. Intelligent precise aeration return control;

4. multi-point gas extraction technology application, energy saving

5. small footprint, simple infrastructure;

6. Combine concentration with decentralized processing to save investment in pipe network;

7. remote monitoring and automation design, low operating and maintenance costs

8. modular assembly design, installation, transportation, upgrade efficient

9. Professional design, integrated with the surrounding environment.

Technical specification

|

Item |

XMP-1 |

XMP-3 |

XMP-5 |

XMP-7.5 |

XMP-10 |

XMP-15 |

XMP-20 |

XMP-30 |

XMP-40 |

XMP-50 |

|

Treating capacity(m 3 /h) |

1 |

3 |

5 |

7.5 |

10 |

15 |

20 |

30 |

40 |

50 |

|

No. of machine parts |

1 |

1 |

1 |

1 |

2 |

2 |

2 |

3 |

4 |

4 |

|

Sludge absorption and primary sedimentation tank |

1.8 |

5.5 |

9 |

14 |

18 |

27 |

36 |

50 |

82 |

100 |

|

Contact oxidtion Mond(m 3 ) |

5.0 |

14.5 |

24 |

36 |

44 |

63 |

83 |

130 |

170 |

200 |

|

Surface load secondary sedimentation tank(m 3 /h) |

1.2 |

1.3 |

1.3 |

1.3 |

1.2 |

1.2 |

1.5 |

1.5 |

1.5 |

1.6 |

|

Disinfection tank(m 3 ) |

0.6 |

1.8 |

2.8 |

4 |

5.5 |

8 |

10 |

15 |

20 |

25 |

|

Weight of biggest part(t) |

5 |

6 |

7 |

10 |

8 |

10 |

10.5 |

10.5 |

10.5 |

12 |

|

Total weight(t) |

5.5 |

6.5 |

8 |

11 |

17 |

20 |

21 |

29 |

38 |

42 |

|

Occupy area(m 2 ) |

6 |

14 |

20 |

30 |

50 |

65 |

75 |

115 |

155 |

185 |

01. We are a manufacturer and we have import and export rights.

02. We produce wonderful environmental protection machines and solutions, pulp and paper making machines and solutions as well as tissue paper converting machinery and solutions,

03. Our main manufacturing facility which spans nearly 30,000m2.

04 . We have achieved a total of 32 patents over the past few years.

05.

Each year the output value of our products can reach up to 150 million RMB, to domestic and overseas.

06.

We are in very close proximity to a very famous port city – Qingdao in northern China, and this location provides us with a plethora of logistics advantages, including: easy and cost effective transport by both air and sea, also.

01. Detailed installation manual and maintenance guideline are provided with the equipment.

02 . Technical training and site-commissioning are available for you.

03. Any equipment issue, we will stand by. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.

01. How to buy your idea products?

A: You can provide us your water sources, water quality, flow rate and ground area (connect us for more details).

02. How to pay?

A: TT and L/C are acceptable and TT will be more appreciated. 30% deposit before producing, 70% balance before loading by TT.

03. What is the delivery time?

A: It depends on order quantities. Generally speaking, the delivery time will be within 4 to 6 weeks.

04. How to pack the products?

A: We use standard package. If you have special package requirements, we will pack as required, but the fees will be paid by customers.

05. How to keep your equipments from corrosion?

A: We use the world-famous paint, like SigmaCoatings, PainBow, etc. What's more, we paint strictly according to the standard process.

06. How do you manufacture your equipment ?

A: Our machining technology includes laser/plasma cutting, automatic welding, CNC cutting and bending.

07. How to install after the equipment arriving destination?

A: We will provide detailed illustrations to you. If it is necessary, we will send technicians to help you. However, the visa fee, air tickets, accommodation, wages will be paid by buyers.