- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≥99.8%

-

Voltage:

-

380V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sokos

-

Dimension(L*W*H):

-

3100*2200*2400

-

Weight:

-

4000 KG

-

Function:

-

Bottle Washing Filling Capping

-

Processing Types:

-

Automatic Bottle Filling Sealing Machine

-

Usage:

-

Beverage Packaging

-

Material:

-

SUS304/316

-

Bottle type:

-

PET Plastic Bottle

-

Filling material:

-

Flowing Liquid

-

Product name:

-

3-in-1 juice filling and capping machine

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 400BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH, 100BPH, 200BPH

-

Packaging Material:

-

Plastic, Wood, Other

-

Filling Material:

-

Juice

-

Filling Accuracy:

-

≥99.8%

-

Voltage:

-

380V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sokos

-

Dimension(L*W*H):

-

3100*2200*2400

-

Weight:

-

4000 KG

-

Function:

-

Bottle Washing Filling Capping

-

Processing Types:

-

Automatic Bottle Filling Sealing Machine

-

Usage:

-

Beverage Packaging

-

Material:

-

SUS304/316

-

Bottle type:

-

PET Plastic Bottle

-

Filling material:

-

Flowing Liquid

-

Product name:

-

3-in-1 juice filling and capping machine

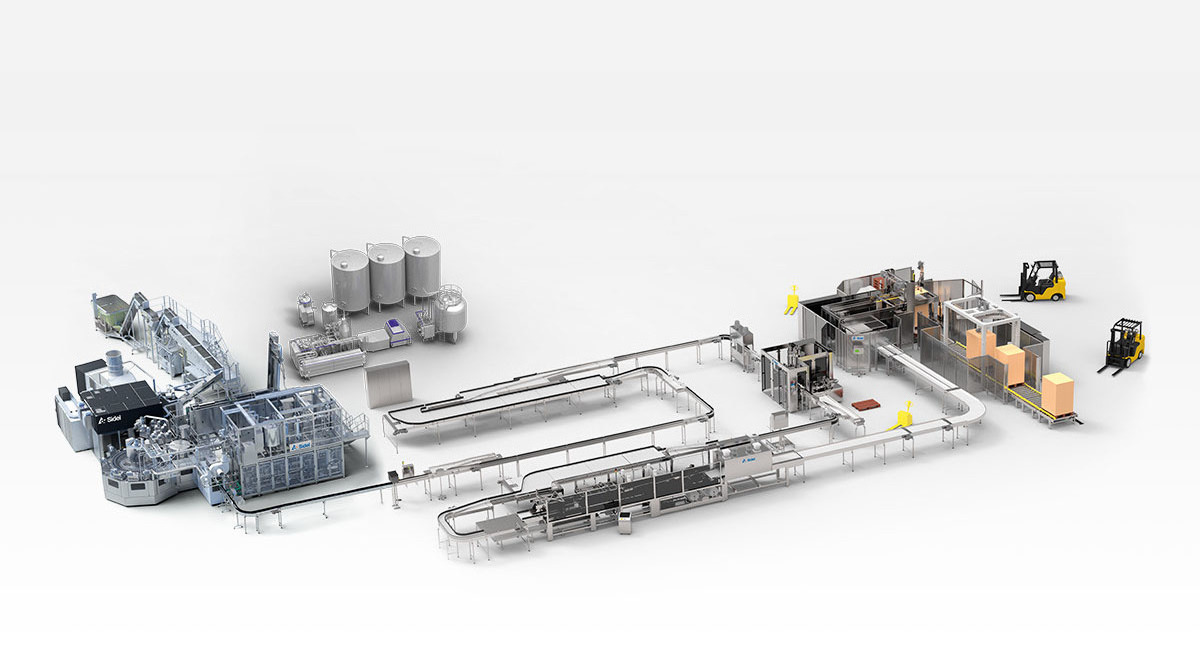

Small Scale Complete Juice Beverage Hot Filling Fruit Juice Processing Production Line For A-Z Machinery

We are confident about our product quality because of the Quality Assurance System backed by technical capabilities and productioncapacity. We believe “all steps in production are quality control processes”.

Final Products

Capacity(500ml bottles)

:2000-20000BPH

Suitable bottle shapes

:Glass bottle or aluminum bottle

Bottle diameter(mm)

:φ50-115mm

Bottle height (mm) :160-320mm

Bottle height (mm) :160-320mm

Products Description

Small Scale Complete Juice Beverage Hot Filling Fruit Juice Processing Production Line For A-Z Machinery

-This glass bottle beverage plup filling machinery has washer,filler,capper three functions in one body, total process is

automatic.

automatic.

-Automatic 500ml Bottle Bottled beverage packing and Filling Machine

-It is suitable for Glass/Aluminum bottled drinking

beverage filling. It applies advanced micro-pressure gravity type filling principle, with perfectrecirculation system, also can reach separately gas return, without contacting with material, avoid secondary pollution and oxygen.

beverage filling. It applies advanced micro-pressure gravity type filling principle, with perfectrecirculation system, also can reach separately gas return, without contacting with material, avoid secondary pollution and oxygen.

-It is made of high quality SUS304/316 stainless steel.

-Main components of beverage packaging machine are processed precisely by CNC machine tool.

Details Images

About Bottle Filling Machine

- All

304/316 stainless steel

construction

-

Air conveyor entering bottles

- Stainless steel entrained plastic pads ensure minimal bottle bumping during washing.

- Durable cleaning pump,

high precision filling nozzle

- Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

- Capping effect is stable and reliable,

Defective rate ≤0.2

%

Special design for washing part

-Washing part accept inductive water spray design, saving water consumption.

Special design for capping part

- The upper cover part adopts a detachable design, which is convenient to adjust the torque.

Main Features.

1:Intelligent:

The machine operation is controlled by the advanced touch screen, which can realize human-machine communication.

2:Convenience: To change the size of the filling bottle, only the star wheel and other components need to be replaced. 3:Cleaning: The parts in contact with the medium are made of stainless steel, with no dead ends in the process and easy to clean.

4:Conveying: It adopts an efficient capping system and has a complete self-control protection device.

5:Safety: Equipped with perfect overload protection device to protect equipment and operators.

2:Convenience: To change the size of the filling bottle, only the star wheel and other components need to be replaced. 3:Cleaning: The parts in contact with the medium are made of stainless steel, with no dead ends in the process and easy to clean.

4:Conveying: It adopts an efficient capping system and has a complete self-control protection device.

5:Safety: Equipped with perfect overload protection device to protect equipment and operators.

Product Paramenters

|

Model

|

RCGF8-8-4

|

RCGF14-12-5

|

RCGF18-18-6

|

RCGF24-24-8

|

RCGF32-32-10

|

||||

|

Production capacity(600ml) (B/H)

|

2000~2500

|

3000~3500

|

6000~7000

|

8000~10000

|

11000~13000

|

||||

|

suitable bottle specification(mm)

|

φ=50-110 H=170 volume=200-2250ml

|

|

|

|

|

||||

|

Washing pressure(kg/cm2 )

|

2~3

|

|

|

|

|

||||

|

Motor power(kw)

|

Main motor 2.2kw

|

Main motor 3kw

|

Main motor 3.8kw

|

Main motor 5.5kw

|

Main motor 7.5kw

|

||||

|

Overall dimensions (mm)

|

2400×1650 ×2500

|

2400×1830 ×2400

|

3100×2200 ×2400

|

3800×2800 ×2900

|

4600×2800 ×2900

|

||||

|

|

|

|

|

|

|

||||

|

Weight (kg)

|

2500

|

3500

|

4000

|

6500

|

8500

|

||||

Related products

Why Choose Us

Zhangjiagang Sokos Machinery Co., Ltd.

is located in Zhangjiagang City, Jiangsu Province, China, and is one of the professional manufacturers with more than

25 years of experience in this field

.

Sokos Machinery has a modern workshop of

5,000 ㎡

by our QC team, and each equipment that leaves the factory will be debugged and inspected by a number of experienced engineers.

In order to give customers a better experience, we are equipped with an independent technology research and development department.. The

high-precision filling nozzle

and

the latest constant torque capping

device are developed from this.

We provide customers with:water, juice, tea beverages, carbonated beverages, beer and other liquid filling lines. Our production lines have been installed in

more than 56 countries.

"Quality, Integrity" is the foundation of Sokos's existence. Sokos is well received by the majority

of users. The company has established a solid position in the industry.

of users. The company has established a solid position in the industry.

Sokos provides beverage filling solution, and warmly welcomes people from all walks of life to visit our company for inspection and guidance. Achieve win-win cooperation!

Invention patent

Our R&D team has been constantly innovating in the research and development of beverage machinery accessories, focusing on providing customers with a better experience.

Certificates.

We have been producing our goods with mature technique and first-class quality. Our products are not only marketed inland, but also exported to all over the world, Such as: Africa, Mid East, South Asia, South America. We believe

truthfulness,conscientiousness, enterprising spirit, continuous improvement and creativeness in running business, which helps our finest products enter the market.

truthfulness,conscientiousness, enterprising spirit, continuous improvement and creativeness in running business, which helps our finest products enter the market.

Our Manufacturer Factory.

At present, we manufacture and provide the following lines to our customers:Beverage Filling Complete Line、water treatment plants、water filling machine、beverage filling machine、beverage preparation system、packages equipment coding machine、labeling machine、PE Film Shrink Wrapping Machine、Injection machine、Blow Molding Machine.We welcome distributors and factory owners from around the world to cooperate with us and look forward to receiving your inquiries in the near future.

Professional engineer team

Have 10+ years’experience

Factory inspection

Control the quality of products

Bottle Design

Provide plant layout, bottle design, etc...

Motor brand

Use internationally renowned brands

Our customers

Our products are exported to all over the world

Recommend Products

FAQ

SOKOS MACHINERY - Alibaba Verified Packaging Machinery Supplier - CE SGS

Q: Are you a manufacturer or a trading company?

A: We are the source factory with

25 years' manufacturing experience

in beverage machinery. Located in Jinfeng Town, Zhangjiagang City, Jiangsu Province, China. The transportation is convenient, very close to Pudong Airport and Sunan Shuofang Airport. If your itinerary includes a factory visit, we will pick you up.

Q: How long is your delivery cycle after you order the machinery?

A: Generally it is

40 working days

.

Q: Do you have a relevant after-sales system?

A: We have a Perfect after-sales system.

1: 12 months warranty.

2: Many-to-one service, we will solve basic problems through phone, email, whatsapp, WeChat and video calls. The operation manual will be sent with the machine or via e-mail.

3: If conditions permit, the engineer will go to the buyer's factory to install and test the machine, and train the buyer's staff on how to operate and maintain the machine.

Q: If I want to buy a machine, what information do I need to tell you?

A:

1: What liquid do you want to fill?

2: What is the capacity and height of the bottle?

3: What is the output in one hour?

4: Related water quality analysis reports, etc.

5: Required mechanical voltage

Q:How to ensure that you deliver goods on time and ensure the safety of my funds?

1:We guarantee the on-time delivery and quality of the equipment you purchase through the credit insurance service of the Alibaba platform.

2:With the letter of credit, you can easily lock in the delivery time.

3:After visiting the factory/video watching the factory, you can ensure the authenticity of our bank account.

Q:How do you ensure the quality of the machine?

1:To ensure the accuracy of parts. We are equipped with a variety of professional processing equipment, plus professional processing methods accumulated over the years.

2:Before the machine is assembled, each part is inspected by the inspector.

3:Assemble machines, all with masters with more than 5 years of work experience to operate.

4:After all the equipment is completed, we will connect all the machines and allow

at least 12 hours

for a complete production line. To test its stability

Hot Searches