- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Redbull

-

Model Number:

-

W0.5-W40

-

Usage:

-

Mass finishing polishing

-

Product name:

-

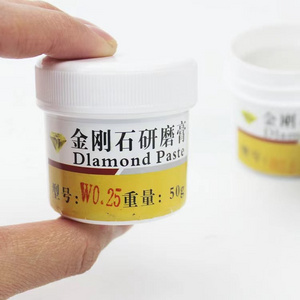

Diamond Grinding Paste Polishing Paste

-

Grain Size:

-

320#~10000#

-

Model#:

-

W0.5-W40

-

Application:

-

Glass, ceramics, gemstones, hard alloys and etc.

Quick Details

-

Type:

-

Diamond Grinding Paste

-

Abrasive Grain Sizes:

-

320#~10000#

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Redbull

-

Model Number:

-

W0.5-W40

-

Usage:

-

Mass finishing polishing

-

Product name:

-

Diamond Grinding Paste Polishing Paste

-

Grain Size:

-

320#~10000#

-

Model#:

-

W0.5-W40

-

Application:

-

Glass, ceramics, gemstones, hard alloys and etc.

Product Description

|

Product Name

|

Needle Tube 5g Oil Soluble Diamond Grinding Paste Polishing Paste W0.5-W40 Abrasives Diamond Lapping Polishing Paste

|

|

Selection of Diamond Grinding Paste

|

It is mainly determined based on the roughness requirements and processing efficiency of the processed workpiece, as well as the original roughness of the workpiece. If there is a large margin and high processing efficiency is required, coarser grain sizes can be selected; For those with small margin and high requirements for roughness, finer grain sizes can be selected, so rough grinding,fine grinding is selected based on the roughness requirements of the workpiece.

|

|

Features

|

Convenient and fast to use The needle tube style provides a comfortable feel and better control of the dosage used. Transparent materials allow for better observation of the remaining amount

|

|

Precautions

|

Select appropriate grinding equipment and grinding paste based on the material and processing requirements of the workpiece. The commonly used grinders are blocks and plates made of materials such as glass, castings, steel, aluminum, organic glass, etc. The

diluent is used for refining. |

|

Cautions

|

1. Diamond grinding is a precision machining process that requires a clean environment and clean tools. The tools used must be dedicated to each grain size and must not be mixed.

2. Before changing to grinding paste with different grit during the processing, the workpiece must be carefully cleaned to prevent the coarse particles from the previous filling from mixing with the fine-grained grinding paste and scratching the workpiece.

3. When using, squeeze a small amount of grinding paste into a container or directly onto the grinding device, and dilute it with kerosene. The general water to paste ratio is 1:1, which can also be adjusted according to on-site usage.

4.After grinding, the workpiece should be cleaned with gasoline and kerosene.

|

|

Application

|

glass, ceramics, gemstones, hard alloys, natural diamonds, measuring tools, cutting tools, optical instruments, high gloss workpieces

|

Specification

Product Characteristics

Factory View

Exhibition

Customer Photos

Hot Searches