1.

High Speed Feeder, 4 suckers for lifting and 4 suckers for conveying structure. Max Speed 12000 sheets/h

2.The paper feeding table has upper and lower over-limit protection

3.The height of non-stop feeding can reach1300mm, pre-stacking device, non-stop feeding

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JIALITE

-

Dimension(L*W*H):

-

7505*1995*1960mm

-

Weight:

-

5800 KG

-

Max Paper Size:

-

1080*880mm

-

Min Paper Size:

-

360*290mm

-

Speed:

-

10-110m/min

-

Overlap Precision:

-

≤±1.5mm

-

Film Thickness:

-

10/12/15 micrometer

-

Non-Stop Feeding Height:

-

1300mm

-

Collector Paper Height(incl. pallet):

-

1300mm

-

Working power:

-

25-28kw

-

Main motor power:

-

5.5kw

-

Roll Working Pressure:

-

15Mpa

Quick Details

-

Packaging Type:

-

Film

-

Packaging Material:

-

Plastic, Metal

-

Driven Type:

-

Mechanical

-

Voltage:

-

380V

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

JIALITE

-

Dimension(L*W*H):

-

7505*1995*1960mm

-

Weight:

-

5800 KG

-

Max Paper Size:

-

1080*880mm

-

Min Paper Size:

-

360*290mm

-

Speed:

-

10-110m/min

-

Overlap Precision:

-

≤±1.5mm

-

Film Thickness:

-

10/12/15 micrometer

-

Non-Stop Feeding Height:

-

1300mm

-

Collector Paper Height(incl. pallet):

-

1300mm

-

Working power:

-

25-28kw

-

Main motor power:

-

5.5kw

-

Roll Working Pressure:

-

15Mpa

Product Apperance

Products Description

NFY-B series pre-coat glue automatic thermal laminating machine as a professional equipment used for plastic film laminating on the surface of paper printed matter. Improving the printing matter grades, and achieve the purpose of dust-proof, waterproof, oil proof.

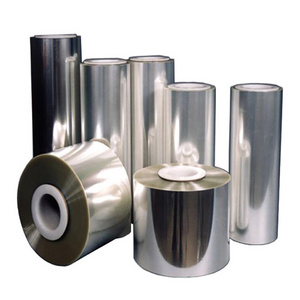

Thermal laminating (Pre-coated /thermal film)

Film: OPP, BOPP, PET, SOFT TOUCH FILM.

Thermal laminating (Pre-coated /thermal film)

Film: OPP, BOPP, PET, SOFT TOUCH FILM.

Specifications for

NFY-B1080 Business Card Automatic Cardboard BOPP OPP Pre-Caoting Film Laminating Machine

|

Model

|

NFY-B1080

|

|

Max Paper Size

|

1080*880mm

|

|

Min Paper Size

|

360*290mm

|

|

Speed

|

10-110m/min

|

|

Paper Thickness (Round Knife)

|

100-500gsm (Above 100gsm easy to adjust, E type corrugated paper)

|

|

Overlap Precision

|

≤±2mm

|

|

Film Thickness

|

10/12/15 micrometer

|

|

Common Glue Thickness

|

4-10g/m2

|

|

Pre-Gluing Film Thickness

|

1005,1006,1206g/m2 (1508 和1208 suit deep embossing paper)

|

|

Non-Stop Feeding Height

|

1300mm

|

|

Collector Paper Height(incl. pallet)

|

1300mm

|

|

Main motor power

|

5kw

|

|

Whole machine power

|

35kw

|

|

Working power

|

20-25kw

|

|

Power

|

380V-50Hz-3P

|

|

working Pressure

|

15Mpa

|

|

Air consumption

|

80m³/h

|

|

Cable Thickness

|

25mm

2

|

|

Weight

|

6500kgs

|

|

Dimension (layout)

|

7300*1995*1960mm

|

|

Loading

|

40HQ

|

Details Images

FEEDING UNIT

CONVEYING TABLE

1.

The conveying table adopts customized stainless steel corrugated board

2.The brush wheel and rubber pressing wheel move smoothly

2.The brush wheel and rubber pressing wheel move smoothly

SIDE PULL GUAGE

1.

Servo motor overlap, improve accuracy of lap, error≤±2mm

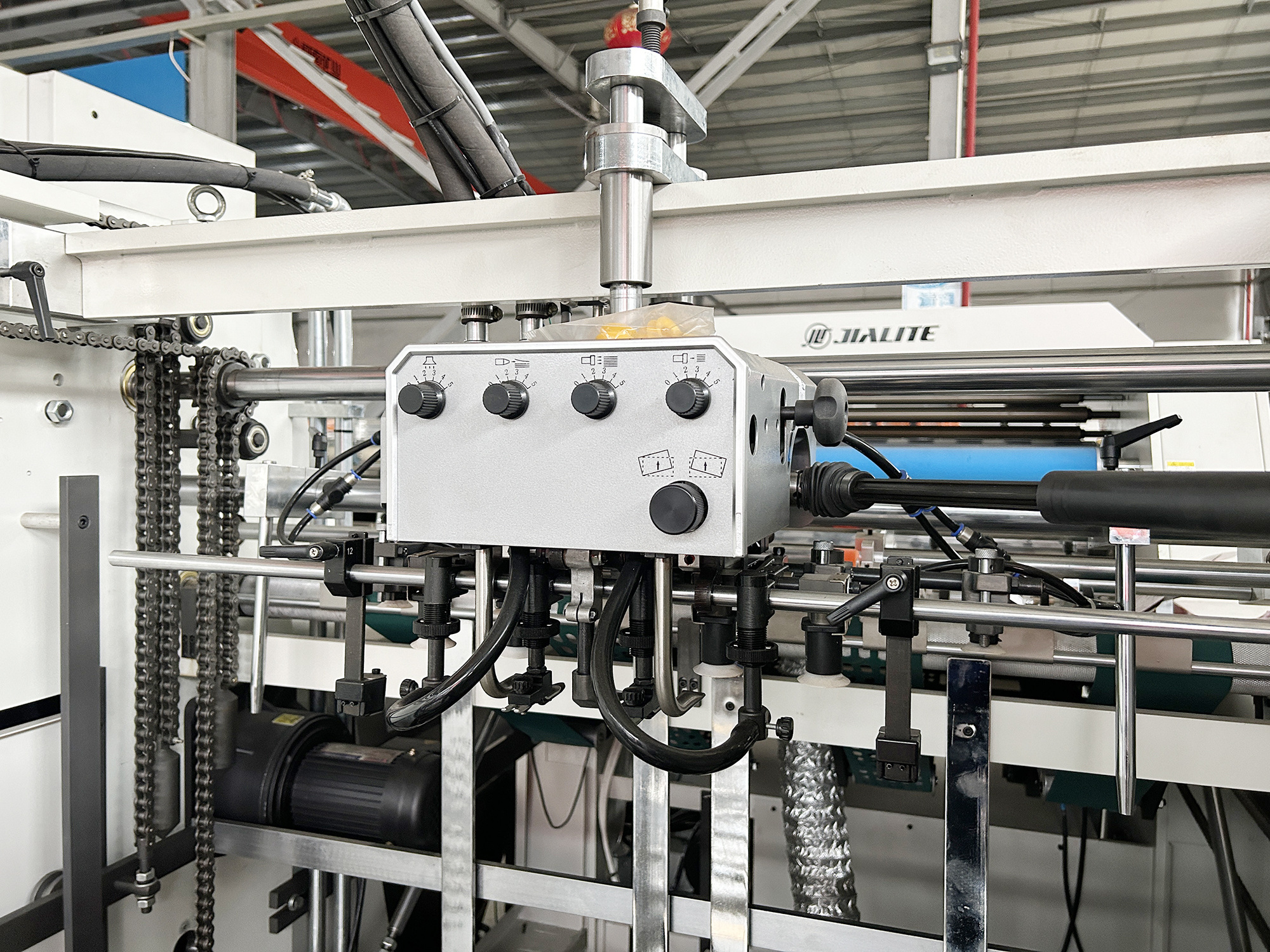

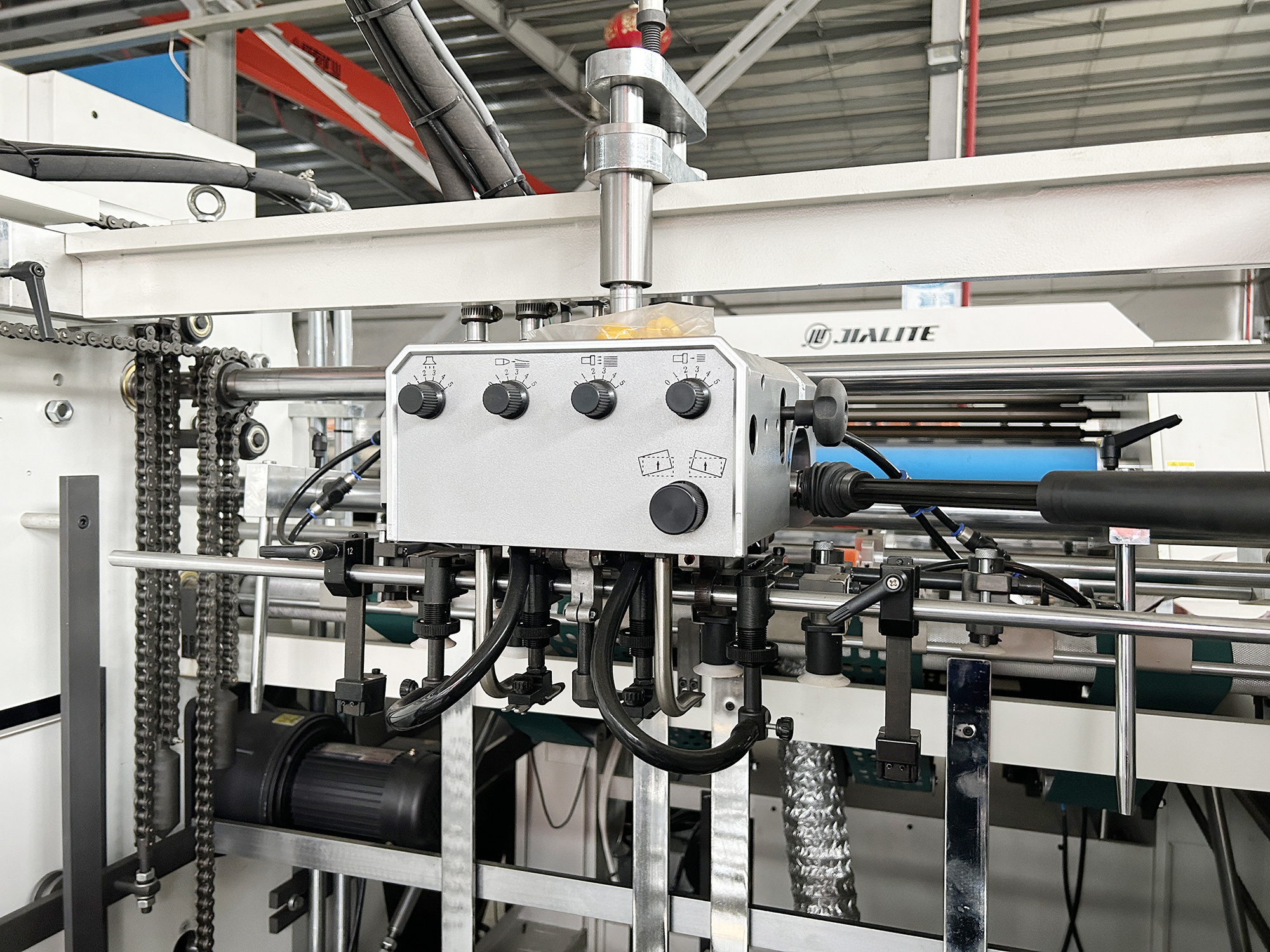

LAMINATOR HOST

1.

The hot-press steel roller (Dia.380mm) adopts electromagnetic heating system, Rapid heating, energy saving and environmental

protection.

2.The pressing pressure is controlled by two sets of hydraulic cylinders and an automatic hydraulic system, which can balance the

pressure on the upper and lower rollers

3.The surface of the pressure roller is covered with a special strength rubber layer.

protection.

2.The pressing pressure is controlled by two sets of hydraulic cylinders and an automatic hydraulic system, which can balance the

pressure on the upper and lower rollers

3.The surface of the pressure roller is covered with a special strength rubber layer.

TOUCH SCREEN

1.Simple design of total control touch screen.2.Support Internet of things remote control, after-sales service more convenient.

3.Language customized

4.one-click activation of multiple units.

3.Language customized

4.one-click activation of multiple units.

DISC KNIFE CUTTING

1.The paper cutter is equipped with a tension controller, the an anti-curl device to ensure that the thin paper flat and not curled.

2. The paper cutting part contains grinding wheel, disc knife and hot knife for slitting, meeting customers' requirements for

slitting films of different materials.

2. The paper cutting part contains grinding wheel, disc knife and hot knife for slitting, meeting customers' requirements for

slitting films of different materials.

3.

The bounce roller is controlled by an independent motor, and the paper can be separated by using the speed difference

COLLECTOR UNIT

1.The non-stop collector height can reach 1300mm. When the stack is almost full, the delivery conveyor belt will automatically extend to accept the paper. The collector platform will drop. After the tray is replaced, the platform will recycle and complete the non-stop collector.

2.Adopt pneumatic paper sorting structure to ensure the paper in the good order.

3.Avoid paper breakage due to excessive speed hitting the baffle.

4.Counting electric eye: the number of running paper is read by the display, and the data can be cleared and totalized.

5.Induction electric eye, sensing the length of the paper, if the length of the paper changes, the belt will accelerate, and the baffle of the collector will overturn, paper is kicked out..

2.Adopt pneumatic paper sorting structure to ensure the paper in the good order.

3.Avoid paper breakage due to excessive speed hitting the baffle.

4.Counting electric eye: the number of running paper is read by the display, and the data can be cleared and totalized.

5.Induction electric eye, sensing the length of the paper, if the length of the paper changes, the belt will accelerate, and the baffle of the collector will overturn, paper is kicked out..

Hot Searches