The crankshaft converts reciprocative motion to rotational motion. It contains counter weights to smoothen the engine revolutions. There are two types of crankshaft, the monolithic type,used for multi-cylinder engines, and the assembled type ,fabricated from separate elements, which is mainly used for motorcycles.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

CR538240

-

Product name:

-

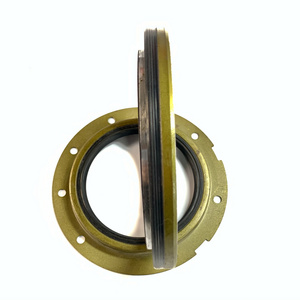

For John-Deere Tractor Rear Crankshaft Oil Seal

-

Colors:

-

Customers Required

-

Certificate:

-

ISO9001/TS16949

-

Feature:

-

High Temperature Resistance

-

Type:

-

Crankshaft Rear Oil Seal

-

Material type:

-

NBR

-

Pressure tolerance:

-

0-1000 fpm

-

OEM:

-

Provided

-

Hardness:

-

70 Shore

-

Packing:

-

Plastic Bags +Carton

Quick Details

-

Size:

-

CR538240

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

SNAK

-

Model Number:

-

CR538240

-

Product name:

-

For John-Deere Tractor Rear Crankshaft Oil Seal

-

Colors:

-

Customers Required

-

Certificate:

-

ISO9001/TS16949

-

Feature:

-

High Temperature Resistance

-

Type:

-

Crankshaft Rear Oil Seal

-

Material type:

-

NBR

-

Pressure tolerance:

-

0-1000 fpm

-

OEM:

-

Provided

-

Hardness:

-

70 Shore

-

Packing:

-

Plastic Bags +Carton

SNAK Oil Seal Factory

--

Professional oil seal manufacturer--

|

Certificate

|

ISO9001/Ts16949

|

|

Advantage

|

Factory Direct Sale

|

|

Transport Package

|

PE Bag + Carton Box

|

|

HS Code

|

8487900000

|

|

Maximum shaft surface speed

|

3600 fpm

|

|

Pressure tolerance

|

0-1000 fpm

|

|

Typical application

|

Crankshaft rear Oil Seal

|

|

Part position

|

Shaft Seal

|

Crankshaft seal

The crankshaft seal is the primary barrier that keeps oil from leaking from the rear or front end of the crankshaft.

Over time, crankshaft seals can dry out, break, or wear a groove into the crankshaft, allowing oil to leak.

Some crankshaft seals come with a steel wear sleeve which creates a new surface for the seal.

Reason for leaking

01.

quality of seal, cheap aftermarket copies of OEM parts which are poorly made

02.

seal not put in straight causing rapid wear of seal lip and oil egress due to wipe over

03.

new seal put in on edge of wear groove on crank causing flipping of seal in and out of groove

04.

poor fitting of seal causing damage to lip or dislodging of spiral supporting spring

05.

poor finish on shaft surface causing erosion of seal

06.

excessive crankcase pressure due to poor installation of/lack of PCV system causing leak of oil/blow out of seal / dislodging of seal.

Hot Searches