- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

accuracy

-

Voltage:

-

380V/220V 50Hz or By Order

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Beyond

-

Dimension(L*W*H):

-

customized

-

Weight:

-

4500 KG

-

Warranty of core components:

-

1 years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine:

-

aerated drink bottling machine

-

Material:

-

SUS304

-

Control:

-

PLC

-

Filling type:

-

Carbonated Drink

-

Processing:

-

Rinsing, Filling, Sealing

-

Color:

-

Sliver grey

-

Certification:

-

CESGS

-

Screen:

-

Touch

-

After Warranty Service:

-

1 Year/12 Months

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Other, cola, soda water, lemonade, Pepsi, Ginger ale, Perrier

-

Filling Accuracy:

-

accuracy

-

Voltage:

-

380V/220V 50Hz or By Order

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Beyond

-

Dimension(L*W*H):

-

customized

-

Weight:

-

4500 KG

-

Warranty of core components:

-

1 years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine:

-

aerated drink bottling machine

-

Material:

-

SUS304

-

Control:

-

PLC

-

Filling type:

-

Carbonated Drink

-

Processing:

-

Rinsing, Filling, Sealing

-

Color:

-

Sliver grey

-

Certification:

-

CESGS

-

Screen:

-

Touch

-

After Warranty Service:

-

1 Year/12 Months

Carbonated drink

Filling Machine

Product Description

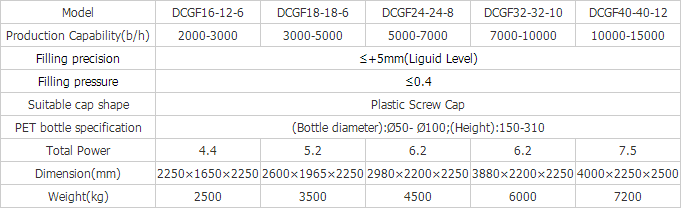

Specification

Different filling capacities

8-8-3 Bottle Filling Line Capacity:1000-2000 bottles per hour.

14-12-5 Bottle Filling Line Capacity:2000-3000 bottles per hour.

16-12-6 Bottle Filling Line Capacity:4000-6000 bottles per hour.

24-24-8 Bottle Filling Line Capacity:10000-12000 bottles per hour.

18-18-6 Bottle Filling Line Capacity:6000-8000 bottles per hour.

40-40-12 Bottle Filling Line Capacity:20000-24000 bottles per hour

32-32-10 Bottle Filling Line Capacity:12000-15000 bottles per hour.

Soda pop processing Feature :

* This cola drink filling machine is mainly used in the carbonted beverage filling with gas.

* It is mainly used in washing, filling and sealing carbonated beverage such as carbonated drinks, cola, iced tea and carbonated drink water and so on.

* It is composed by rotary washer, balanced pressure filler, screw type sealer and conveying system. The automatic carbonated beverage filling machine capacity is from 8000b/h to 15000b/h

* The cola drink filling machine construction is advanced, The performance is stable. The operation and maintain are easy. And the speed of automatic carbonated beverage filling machine can be adjusted infinitively and accords with the standards.

* This cola drink filling machine is mainly used in the carbonted beverage filling with gas.

* It is mainly used in washing, filling and sealing carbonated beverage such as carbonated drinks, cola, iced tea and carbonated drink water and so on.

* It is composed by rotary washer, balanced pressure filler, screw type sealer and conveying system. The automatic carbonated beverage filling machine capacity is from 8000b/h to 15000b/h

* The cola drink filling machine construction is advanced, The performance is stable. The operation and maintain are easy. And the speed of automatic carbonated beverage filling machine can be adjusted infinitively and accords with the standards.

Soda pop processing Application:

1.The series equipment is used in production gas containing water of PET polyester bottle-packing carbonated beverage, such as Coca cola, Pepsi-cola, Spirit drink etc.

2.It carries out washing bottle, filling and capping on one machine. The whole machine designing is reasonable. The appearance is beautiful and the maintenance is convenient.

3.It adopts bottle handing technology to make changing bottle more convenient, faster and easier. The main machine adopts advanced PLC control ,Touch screen and no-bottle, no-cap system.

4.The key electric elements are from famous international brand.

1.The series equipment is used in production gas containing water of PET polyester bottle-packing carbonated beverage, such as Coca cola, Pepsi-cola, Spirit drink etc.

2.It carries out washing bottle, filling and capping on one machine. The whole machine designing is reasonable. The appearance is beautiful and the maintenance is convenient.

3.It adopts bottle handing technology to make changing bottle more convenient, faster and easier. The main machine adopts advanced PLC control ,Touch screen and no-bottle, no-cap system.

4.The key electric elements are from famous international brand.

|

Configuration list

|

supply

|

Brand

|

|

No. Name

|

Manufacturer

|

Remark

|

|

1 Main motor

|

Wannan

|

stand

|

|

2 Rinsing pump

|

Nanfang pump

|

stand

|

|

3 Liquid input pump

|

Nanfang pump

|

stand

|

|

4 transducer

|

Mitsubishi

|

Electric cabinet

|

|

5 PLC

|

Mitsubishi

|

Electric cabinet

|

|

6 Cable

|

China

|

Connection cable

|

|

7 AC contactor

|

siemens

|

Electric cabinet

|

|

8 thermo relay

|

Schneider

|

Electric cabinet

|

|

9 buzzer

|

Taiwan

|

Electric panel

|

|

10 Proximity switch

|

China

|

Cap-feeder and cap tester

|

|

11 Photoelectric switch

|

China

|

Cap testing system

|

|

12 Photoelectric switch

|

China

|

Cap unscrambling system

|

|

13 Photoelectric switch

|

China

|

Bottle stopping system

|

|

14 Liquid level switch

|

Taiwan

|

Hydraulic cylinder

|

|

15 Magnetic valve

|

Airtac

|

Filling valve

|

Overturning mechanism of bottle washing machine

It mainly composes of bottle washing clamp, upper rotary plate, guide rail, water distributing plate, shield, water spraying device, water tray etc.

Bottle washing clamp rotates with the upper rotary plate, and open the bottle mouth clamp with elastic distortion when contacting the bottle feeding star-wheel, which can clamp the bottle neck, then overturns at 180° along the guide rail, bottle mouth may become downwards for cleaning and drying the bottle with water, then overturn for 180°, bottle mouth becomes upwards and then conveyed with the star-wheel; shield can prevent sprinkling of cleaning water; water distributing plate can deliver the cleaning water from the still parts to the rotary parts.

Bottle filling mechanism

It has 8 filling valves. It is quick, steady and accurate. The beverage feedback system is well designed, the gas can be fed back separately, has no contact with beverage, reduce the second time pollution and oxidation..

Capping mechanism

Capping mechanism composes of cap separating mechanism, capping machine and cap arranging mechanism.

The machine is designed on the base of Alcoa (France) technology. It adopts magnetic moment capping, which has the function of unload the overloading force on the cap, so the capping head have the function of protect the cap from damage. If the neck size and cap of your bottle is the same, you do not need to change any part.

Additionnal Information

We also provide water treatment system ,bottle blowing machine ,conveyor,Ink printer ,labeling machine,packing machine, to build the complete production line.

Hot Searches