- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KERUI

-

Size:

-

Customers' Requests

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Henan, China

-

Model Number:

-

AL95

-

Brand Name:

-

KERUI

-

Size:

-

Customers' Requests

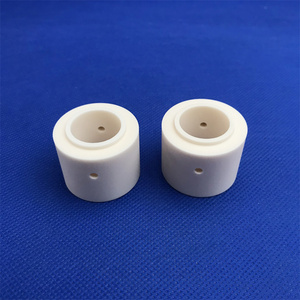

Alumina Ceramic Tube:

Alumina Ceramic tubes are high-performance ceramic components made primarily from aluminum oxide (Al2O3), which is also known as corundum. These tubes possess excellent mechanical strength, wear resistance, and chemical stability, making them ideal for use in harsh environments and under extreme conditions.

|

Characteristic

|

Unit

|

AL95

|

AL99

|

|

Aluminum oxide content

|

/

|

95%

|

99%

|

|

Colour

|

/

|

Ivory white, white

|

Ivory white

|

|

Airtightness

|

/

|

Not breathable

|

Not breathable

|

|

Density

|

g/cm3

|

3.72

|

3.8

|

|

Hardness

|

Moh's hardness

|

8.8

|

9

|

|

Water absorption rate

|

/

|

≤0.2

|

≤0.2

|

|

Bending strength(20 ℃)

|

Mpa

|

304

|

340

|

|

Compressive strength (20 ℃)

|

Mpa

|

1910

|

2210

|

|

Thermal expansion coefficient (25 ℃ to 800 ℃)

|

10-6/℃

|

7.6

|

7.6

|

|

Insulation strength (5mm thickness)

|

AC-kv/mm

|

10

|

10

|

|

Dielectric loss 25℃@1MHz

|

/

|

0.0004

|

0.0006

|

|

Dielectric constant 25℃@MHz

|

/

|

9.2

|

9.5

|

|

Volume electronegativity (20 ℃)(300 ℃)

|

Ω·cm3

|

>10142*1011

|

>10144*1011

|

|

Maximum operating temperature

|

℃

|

1400

|

1600

|

|

Thermal conductivity (25 ℃)

|

W/m·K

|

20

|

34

|

Alumina Ceramic Products Main Features:

High Temperature Resistance:

With a melting point exceeding 2000°C, corundum tubes can withstand severe thermal stress without deformation or degradation.

Excellent Chemical Inertness:

Corundum's low reactivity with most chemicals makes it resistant to corrosion and attack by acids, alkalis, and molten metals.

Low Thermal Conductivity:

They provide excellent thermal insulation, reducing energy loss and maintaining process efficiency in heat transfer operations.

Precision Dimensional Stability:

Manufactured through advanced ceramic forming techniques, corundum tubes offer tight tolerances and precise dimensions.

Wear-Resistant:

The hardness of corundum means these tubes exhibit exceptional wear resistance, reducing maintenance needs and extending service life.

Alumina Ceramic tubes, due to their unique combination of exceptional properties, find wide applications in various industries that require high-temperature stability, chemical inertness, and wear resistance. Here are some key applications:

1.High-Temperature Furnaces:

Corundum tubes are used as linings or components in high-temperature furnaces for heat treatment processes such as annealing, sintering, and firing in the ceramics, glass, metallurgical, and electronics industries.

2.Heat Exchangers:

In thermal processing systems where aggressive chemicals or high temperatures are involved, corundum tubes serve as robust and efficient heat exchanger elements, transferring heat without degrading under extreme conditions.

3.Catalytic Reactors:

The chemical inertness and temperature stability make them suitable for use as catalyst supports or reaction chamber liners in petrochemical plants, pharmaceutical manufacturing, and other chemical processing equipment.

4.Piping Systems: For conveying corrosive fluids or abrasive slurries at elevated temperatures, corundum tubes provide a durable solution that minimizes corrosion, erosion, and wear. 5.Laboratory Equipment: They are utilized in laboratory apparatuses that require resistance to chemical attack and high heat, including crucibles, combustion tubes, and other specialty items.

6.Insulation Components: As an excellent insulator, corundum tubes can be used in insulation jackets for electric heating

elements, providing protection from direct contact with flammable materials.

4.Piping Systems: For conveying corrosive fluids or abrasive slurries at elevated temperatures, corundum tubes provide a durable solution that minimizes corrosion, erosion, and wear. 5.Laboratory Equipment: They are utilized in laboratory apparatuses that require resistance to chemical attack and high heat, including crucibles, combustion tubes, and other specialty items.

6.Insulation Components: As an excellent insulator, corundum tubes can be used in insulation jackets for electric heating

elements, providing protection from direct contact with flammable materials.

7.Semiconductor Industry:

Due to its purity and electrical insulation properties, corundum tubes are employed in semiconductor manufacturing processes where contamination control is critical.

Zhengzhou Kerui Industrial Development Co., Ltd.

Zhengzhou Kerui Industrial Development Co., Ltd. is a branch of Zhengzhou Kerui (Group) Refractory Co., Ltd.. We provide all types of refractory products, including refractory bricks and materials, insulation bricks and materials, kiln shelves and new materials, etc. Kerui Refractory is located in the largest refractory industry zone: Chaohua Town, Xinmi City, Henan Province, China.

Founded in 2004, Kerui Refractory is an international high-tech enterprise integrating R&D and innovation, manufacturing,

solutions and service of high-performance refractory products. Kerui places great importance on R&D. In the past decades, we have obtained one invention patent certificate and more than 20 utility model patent certificates. Kerui insists on technological innovation to provide customers with better products.

Founded in 2004, Kerui Refractory is an international high-tech enterprise integrating R&D and innovation, manufacturing,

solutions and service of high-performance refractory products. Kerui places great importance on R&D. In the past decades, we have obtained one invention patent certificate and more than 20 utility model patent certificates. Kerui insists on technological innovation to provide customers with better products.

Professional R&D Team

Kerui own 50000m² factory ,R&D、production、sales、delivery as one,fully equipped,own patents,support customization.

Professional Sales Team

Kerui has its own sales and service team, proficient in foreign languages, instant communication with customers and can solve customer problems at first time.

Professional Solutions

Kerui has EPC capability, can undertake customer projects, has professional technical experts, according to customer needs to develop the most perfect plan.

Professional After-sale Team

Kerui has its own professional after-sales team, once the customer has any technical problems, it can respond and solve within 1 hour.

Cooperate Partner

Kerui have more than 20 years of technology city store, has supplied Nanshan Copper, Shenhuo Group, Weiqiao aluminum power and other domestic 500 enterprises, quality assurance, honor first.

Kerui Group

Founded in 2004 with a registered capital of 81.8 million Yuan, Zhengzhou Kerui Refractory Material Co. , Ltd. is located in the refractory industry base of Chaohua town, Xinmi Province, After 20 year’s hard work and tenacious struggle , we walked out of a“Product oriented, service first” healthy and rapid development of the road, has developed into a Refractory r & D, production, sales, Product Technology Solutions, Project EPC general contracting services in one of the modern integrated enterprise group.

Testing

- High-temperature reheating/load softening creep test furnace;

- Compressive/flexural strength testing bench for refractory materials;

- Composition testing and inspection platform for refractory materials;

- Laboratory for physical/chemical properties of refractory materials.

- High-temperature reheating/load softening creep test furnace;

- Compressive/flexural strength testing bench for refractory materials;

- Composition testing and inspection platform for refractory materials;

- Laboratory for physical/chemical properties of refractory materials.

Service

- Customized comprehensive solution service;

- Drawing design and materials combination solution;

- Professional construction team;

- Professional after-sales team support and lifetime guarantee;

- Customized comprehensive solution service;

- Drawing design and materials combination solution;

- Professional construction team;

- Professional after-sales team support and lifetime guarantee;

Hot Searches