- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Applicable Industries:

-

Cosmetic, lipstick

-

Voltage:

-

220V/50HZ 380V/60HZ

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SILIAN

-

Dimension(L*W*H):

-

1100*1000*1900mm

-

Weight:

-

350 KG

-

Name:

-

Semi Automatic Liquid Filling Machine

-

Filling material:

-

Flowing Liquid

-

Material:

-

304

-

Function:

-

Filing

-

Product:

-

Custom-Made Models

-

Filling products:

-

lipstick,lipblam,lip oil,lip gloss and so on

-

Suitable for:

-

Cosmetic Cream

-

Filling speed:

-

0-90rmp

-

filling machine barring volume:

-

20L*2

Quick Details

-

Machinery Capacity:

-

4000BPH

-

Packaging Material:

-

Wood

-

Filling Material:

-

Milk, liquid, paste, Cream

-

Filling Accuracy:

-

99%

-

Applicable Industries:

-

Cosmetic, lipstick

-

Voltage:

-

220V/50HZ 380V/60HZ

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SILIAN

-

Dimension(L*W*H):

-

1100*1000*1900mm

-

Weight:

-

350 KG

-

Name:

-

Semi Automatic Liquid Filling Machine

-

Filling material:

-

Flowing Liquid

-

Material:

-

304

-

Function:

-

Filing

-

Product:

-

Custom-Made Models

-

Filling products:

-

lipstick,lipblam,lip oil,lip gloss and so on

-

Suitable for:

-

Cosmetic Cream

-

Filling speed:

-

0-90rmp

-

filling machine barring volume:

-

20L*2

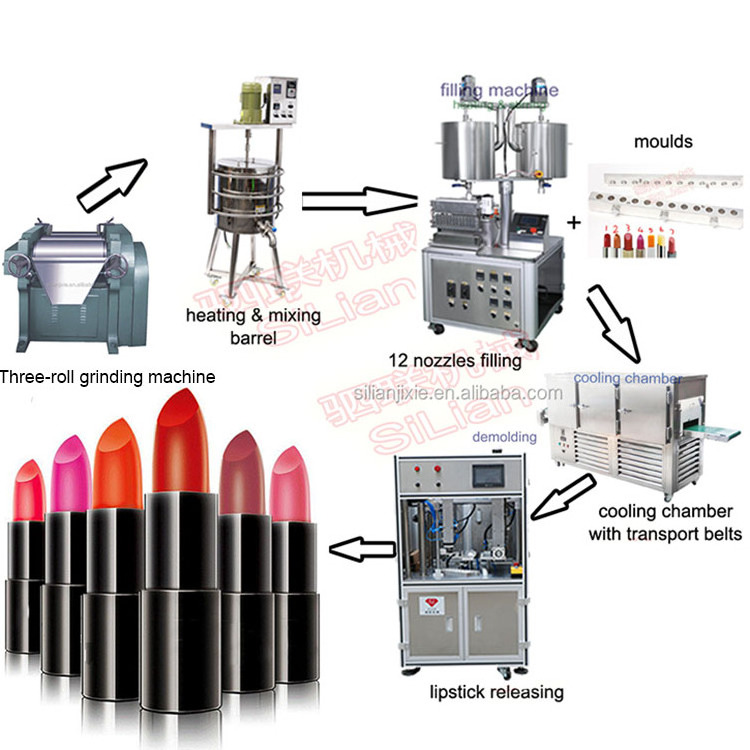

Product Overview

Lipstick production Process

1. First grind the lipstick raw material into the fine color powder with a three-roll grinder

(three-roll grinder)

2. Put the ground toner, wax and other raw materials into the heating mixing bucket to heat into liquid (

heating mixing bucket).

3. Pour the liquid lipstick ingredients into the lipstick filling machine for filling. (Used with lipstick mold)

(Lipstick filling machine)

4. Put the filled lipstick mold on the freezer and freeze it.

(Freezing platform)

5. Finally, the lipstick demoulder will be used to detach the lipstick mold to complete the production of lipstick, which can be directly packaged.

(Lipstick demoulder)

Product introduction

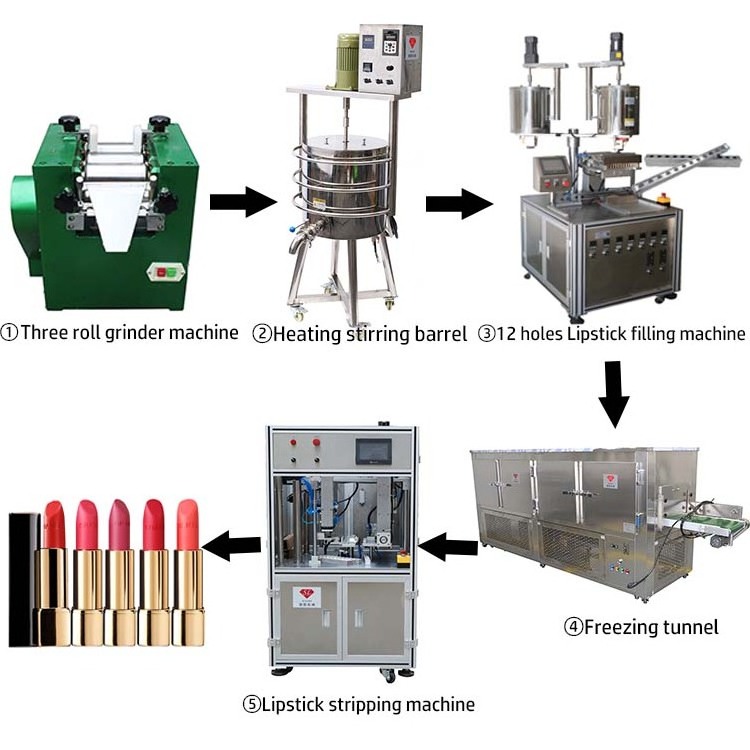

Three roll mill

machine

Mainly used in all kinds of lipstick paste, paint, ink, pigment, plastic and other paste. The machine through the horizontal surface of three rollers mutual extrusion and friction at different speeds to achieve the grinding effect. The equipment is easy to operate, convenient, easy to clean and maintain.

Heating mixing barre

l

Scope of application of this machine: mixing of liquid paste raw materials such as

lipstick, lip balm, lip gloss, lip oil, lip gloss, hair shampoo, body wash, etc. The machine adopts double-layer barrel for oil

separation heating, with heating, stirring, the function of the melt.

lipstick, lip balm, lip gloss, lip oil, lip gloss, hair shampoo, body wash, etc. The machine adopts double-layer barrel for oil

separation heating, with heating, stirring, the function of the melt.

12-hole lipstick filling machine

This machine is designed for liquid paste cosmetics, such as: lipstick, pen lipstick, eyebrow pencil, lip oil, lipstick.... , the use of advanced automation technology (man-machine interface, PLC program control) to simplify the system operation procedures, the overall performance is more stable.

Freezing tunnel

The machine body is made of stainless steel, double-layer temperature insulation to reduce the loss of air conditioning, using air cooling, not easy to form water beads, fast freezing speed. Equipped with conveyor belt, convenient lipstick production process connection, improve efficiency.

lipstick

demoulding machine

The machine is designed for lipstick demoulding. Ordinary shape lipstick, silicone lipstick, diagonal lipstick can be demold, PLC man-machine interface: easy to operate. Can be directly set on the screen to take the mold, dial the mold, put the mold time. Reduce production process and improve work efficiency.

COMPANY PROFILE

SALES AND SERVICE NETWORK

CERTIFICATE

PACKAGE AND TRANSPORT

FAQ

Q1. How About the Installation & Adjustment?

After the equipment arrived at the customer’s site, customers just need connect the machine with eletricity and air compressor,then the machine can run it,as we will shipping the machine with whole packed,customers no need to install the machine again when it arrived your factory.you can use or hire a forklift for unload the machine from the car.

Q2. Are There Training for Customers or our ?

We are responsible for offering the technical training to user. The training content includes the structure and maintenance of the equipment, control and operation of the equipment. Through training, users' technical staff can grasp and the skill of operation and maintenance proficiently, and deal with the general troubles in time. We will appoint qualified technical staff for the guidance.otherwise,we supply with Instructions in English language for each machine.

Q3. How about the "Quality Assurance"?

We are responsible for the faults and damages of the production line caused by our design, technology, manufacture, installation, adjustment and material defect etc. Each machine will be test and factory pre-adjust according to our customers real samples.we can take video for our customers to check before shipping, to make sure the machine quality and customers satisfaction.

Q4.How about the Warranty?

We offer 12 months maintenance period to the problems that caused by our design, manufacture, and material quality, and offer the relevant parts and effective services for free if the problems was caused by above reasons. We will offer a life-long technical support, after service for customers.

Hot Searches