- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ (can be changed)

-

Power:

-

8KW

-

Dimension(L*W*H):

-

3700*1200*2000mm

-

Weight:

-

1600 kg

-

Paper Plate Size:

-

4-13"

-

Paper Grams:

-

100-800g/m2

-

Capacity:

-

Double Stations 40-110pcs/min

-

Air Supply Requirement:

-

0.4Mpa, 0.3cube/min

-

Cylinder Stroke:

-

150mm

Quick Details

-

Production Capacity:

-

100 pcs/min

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

SY

-

Voltage:

-

380V 50HZ (can be changed)

-

Power:

-

8KW

-

Dimension(L*W*H):

-

3700*1200*2000mm

-

Weight:

-

1600 kg

-

Paper Plate Size:

-

4-13"

-

Paper Grams:

-

100-800g/m2

-

Capacity:

-

Double Stations 40-110pcs/min

-

Air Supply Requirement:

-

0.4Mpa, 0.3cube/min

-

Cylinder Stroke:

-

150mm

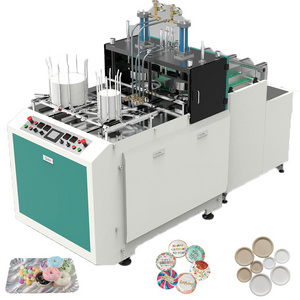

Machine introduction:

High Speed Double Lane Paper Plate Making Machine uses desktop layout, which isolates the transmission parts and molds. The transmission parts are under the desk, molds are on the desk, this layout is convenient for cleaning and maintenance. The machine adopts automatic lubrication, mechanical transmission, hydraulic forming and pneumatic blowing paper, which has the advantages of stable performance and easy operation & maintenance. For electrical parts,PLC, photoelectric tracking, machine with cover for protection, auto intelligent & safe fabrication, can directly support production line.

High Speed Double Lane Paper Plate Making Machine uses desktop layout, which isolates the transmission parts and molds. The transmission parts are under the desk, molds are on the desk, this layout is convenient for cleaning and maintenance. The machine adopts automatic lubrication, mechanical transmission, hydraulic forming and pneumatic blowing paper, which has the advantages of stable performance and easy operation & maintenance. For electrical parts,PLC, photoelectric tracking, machine with cover for protection, auto intelligent & safe fabrication, can directly support production line.

|

Paper Plate Size

|

4-13”

|

|

Paper Grams

|

100-800g/m2

|

|

Paper Materials

|

Base paper, whiteboard paper, white cardboard, aluminum foil paper or others

|

|

Capacity

|

Double Stations 40-110pcs/min

|

|

Power Requirements

|

380V 50HZ

|

|

Total Power

|

8KW

|

|

Weight

|

1600kg

|

|

Specifications

|

3700×1200×2000mm

|

|

Air Supply Requirement

|

0.4Mpa, 0.3cube/min

|

|

Other Notes

|

Customize

|

|

Cylinder Stroke

|

150mm

|

Touch Screen

lt adopts PLC controller and touchscreen (man -machine interface)all the working parameters can beset up on the control panel which is convenient for parameter setting and adjusting.(easy operate)

Counting & Collecting System

The counting &collecting system with sorting function can stack thefinished paper plate in order, which is convenient for packaging andsave the labor costs.

Conveyor System

The finished plates are transferred by the conveyor which is easier for collecting the plate

Plate Forming Mould

Better quality durable mould ,longer service life. the mould design can be customize as customers requirement

Electric System

Quality Brand electric System like Delta, Schneider PLC control system be with Schneider Brand Made in France with Reliable quality

Paper feed system

Paper feeding uses mechanical principle to work, stable performance, compared with the ordinary paper feeding technology, the rejectionrate is greatly reduced.

Hot Searches