- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

5mm

-

Voltage:

-

According to client's need.

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HG

-

Dimension(L*W*H):

-

2600*1800*2400

-

Weight:

-

2500 KG

-

Material:

-

SUS304

-

Rinsing Head:

-

40

-

Filling Head:

-

40

-

Capping Head:

-

10

-

Capacity:

-

8000-10000BPH

-

Suitable bottle type:

-

250ml~750ml

-

Sterile air consumption:

-

0. 2 m3/min(0.4~0.6Mpa)

-

Certification:

-

CE ISO

-

Marketing Type:

-

Hot Product 2019

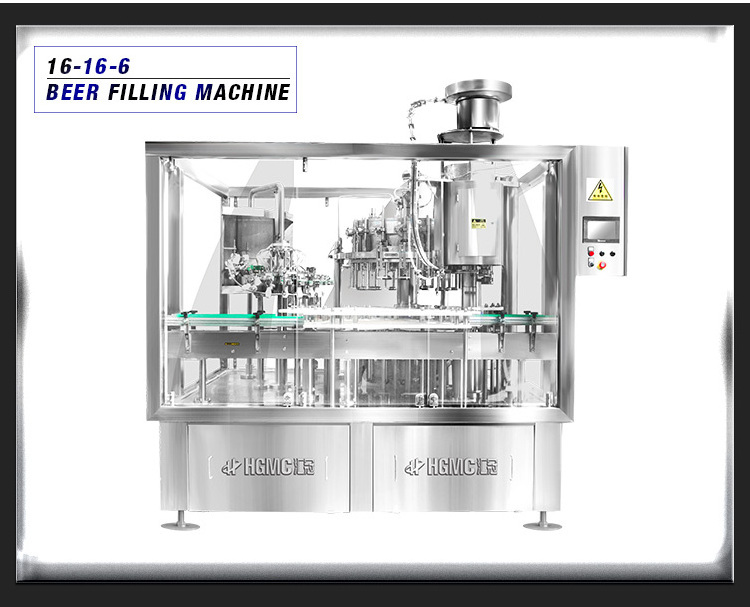

Quick Details

-

Machinery Capacity:

-

8000BPH

-

Packaging Material:

-

Glass

-

Filling Material:

-

Beer

-

Filling Accuracy:

-

5mm

-

Voltage:

-

According to client's need.

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HG

-

Dimension(L*W*H):

-

2600*1800*2400

-

Weight:

-

2500 KG

-

Material:

-

SUS304

-

Rinsing Head:

-

40

-

Filling Head:

-

40

-

Capping Head:

-

10

-

Capacity:

-

8000-10000BPH

-

Suitable bottle type:

-

250ml~750ml

-

Sterile air consumption:

-

0. 2 m3/min(0.4~0.6Mpa)

-

Certification:

-

CE ISO

-

Marketing Type:

-

Hot Product 2019

Automatic beer bottle rinsing filling capping machine beer bottling line

|

Item

|

Parameters

|

Item

|

Parameters

|

|

Washing heads

|

40

|

Vacuum pump

|

0. 40m3/h

|

|

Filling heads

|

40

|

Power

|

main motor: 1.5KW

hopper motor: 0 .18KW vacuum pump motor:1.1KW chain motor: 0.75KW |

|

Capping heads

|

10

|

Dimensions

|

4200×3000×2700(L*W*H)

|

|

Capacity

|

8000-10000BPH

|

N.W.

|

8000kg

|

|

Bottle type

|

height:150~ 300mm

bottle neck:50~85mm bottle diameter: 50-75mm |

Working voltage AC

|

It can be customized by the customers'electrical conditions.

|

|

Air consumption

|

0.15m3/min(0.4~0.6Mpa)

|

Control voltage DC

|

It can be customized by the customers'electrical conditions.

|

|

CO2consumption

|

1.6kg/l000L

|

Frequency converter

|

SIEMEMS

|

|

Water consumption

|

0. 8m3/h

|

PLC

|

SIEMEMS

|

|

Touch screen

|

PLC

|

Pneumatic element

|

SMC

|

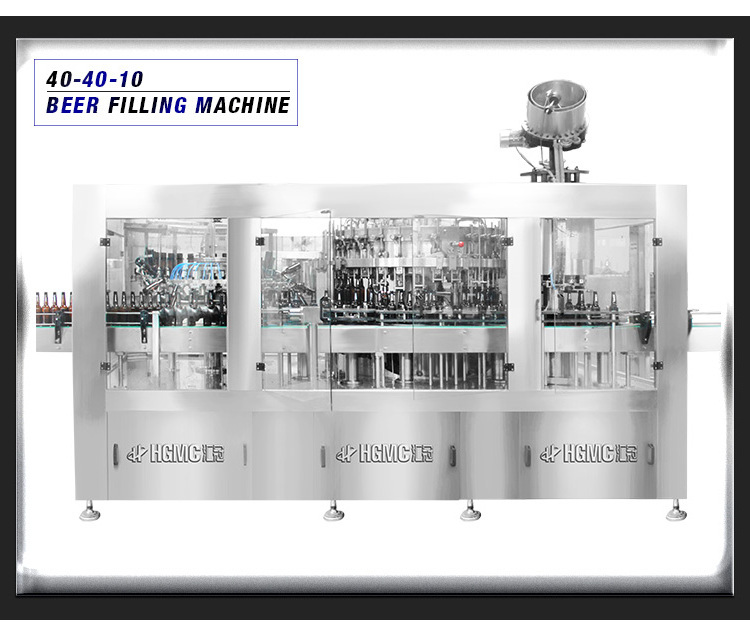

40-40-10 beer bottle filling machine

The machine is the latest design of the beer filling machine 3 in 1 type. It adopts external filling valves, all filling valves were hung on outside of the beer tank which has no contact with the beer inside. The can guarantee the beer won't have any bacteria infection risk. More stable and reliable than original design.

Product advantages

Capacity: 8000-10000 BPH

External filling valve: more stable and sanitary.

Two times of vacuuming: keep your beer pure, prolong its shelf life.

All-mechanical transmission: it will be more stable.

Mechanical three capping heads: worked more harmoniously.

With foaming device: keep the beer quality.

FAQ:

2.Q: Do you have a professional engineer or after-sales team in our country?

A: Yes, our equipment is sold to 150 countries and areas and we have our local after-sales service personnel in Europe, America and Asia.

3.Q: How long is the delivery time?

A: The delivery time of beer equipment is 30-50 working days, the delivery time of filling machine is 45-50 working days.

4.Q:What payment methods are supported?

A:T/T, L/C, Credit Card, VISA, Apple device, Western Union.

5. Q: How long the warranty will be?

A: 3 years warranty for the whole tank and the main equipment, 1 year for the accessories and auxiliaries. 1 Year warranty for filling machine.

6. Q: How about the installation and training?

A: We can supply the installation and training. There are two options. The first option: We could appoint our engineer to your company to debug and repair, as for the cost of this trip such as ticket, visa, accommodation and labor cost shall be on your side. The second option: On-line service will be provided. If still under guarantee period, the necessary accessories and parts will be provided free, the buyer afford the transportation cost.

7.Q: Can I be your company's sales agent?

A: Yes, it’s our pleasure. We very much welcome you to join us. Please contact us to discuss specific details.

8.

The price does not include electrical appliances, etc.

Hot Searches