- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BEDO

-

Voltage:

-

380V

-

Weight:

-

650 KG

-

Dimension(L*W*H):

-

According to different models

-

Name:

-

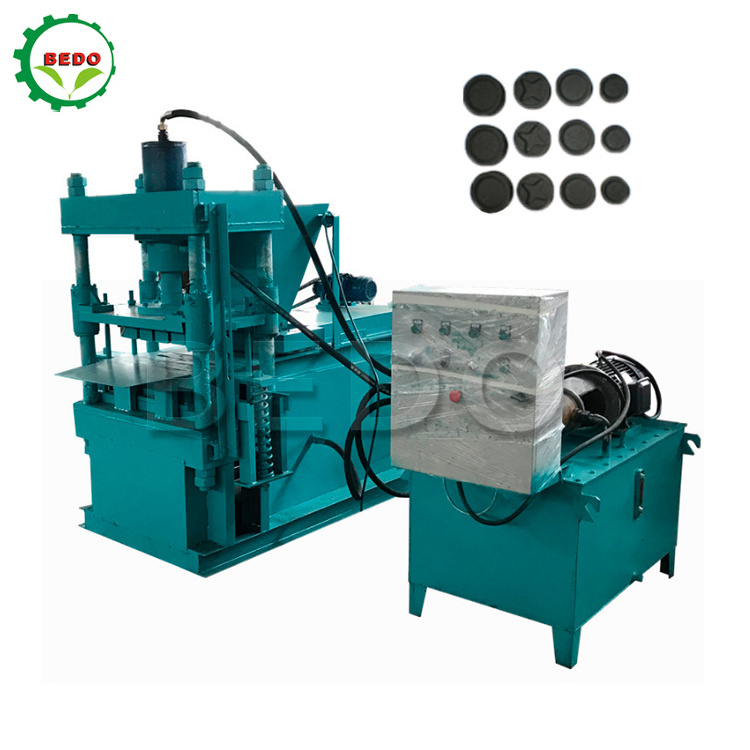

Shisha charcoal press machine

-

Output:

-

9-13pieces/minute

-

Input size:

-

1-5mm

-

Feed moisture:

-

about 20%

-

Raw material:

-

charcoal/coal powder,wooden dust

-

Final shisha size:

-

27-35mm

-

Final shisha shape:

-

round or cubic

-

Pressure:

-

15T

-

Advantage:

-

can change pressure manually

-

After-sales Service Provided:

-

Video technical support

Quick Details

-

Warranty:

-

1 Year

-

Marketing Type:

-

Hot Product 2020

-

Core Components:

-

Engine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BEDO

-

Voltage:

-

380V

-

Weight:

-

650 KG

-

Dimension(L*W*H):

-

According to different models

-

Name:

-

Shisha charcoal press machine

-

Output:

-

9-13pieces/minute

-

Input size:

-

1-5mm

-

Feed moisture:

-

about 20%

-

Raw material:

-

charcoal/coal powder,wooden dust

-

Final shisha size:

-

27-35mm

-

Final shisha shape:

-

round or cubic

-

Pressure:

-

15T

-

Advantage:

-

can change pressure manually

-

After-sales Service Provided:

-

Video technical support

Shisha Charcoal Briquette Machine Shisha Charcoal Making Machine Hookah Arab Tablet Briquette Pressed Machine

Product Description

Charcoal powder tablet pressing machine is a single press automatic tablet pressing machine, can press all kinds of powder materials into round pieces, square and other special-shaped pieces; Mainly used in the production of shisha charcoal. Production of hookah charcoal surface is smooth, adjustable diameter, the size of charcoal piece, strength and hardness can be according to the requirements of customer production, this product is made from selected charcoal powder plus spices and edible glue, can be a match and lit, burning smoke-free, tasteless, non-toxic, for the church lit incense and hookah, appearance, exquisite packaging, in order to meet market demand at home and abroad, Our factory adopts the equipment of new technology, produces the high quality products, and obtains the customer's high praise by the fine exquisite craft.

Specification

|

Model

|

Mechanical

BD-YP9

|

Mechanical

BD-YP12 |

Hydraulic

BD-YP50 |

|

Models number

|

9

|

12

|

50

|

|

Diameter of the tables(mm)

|

15-50

|

15-50

|

12-50

|

|

Capacity

|

40times/minute

9 pieces/time |

40times/minute

12 pieces/time |

4times/minutes

50 pieces/time |

|

Pressure(kn)

|

250

|

250

|

800

|

|

Power(kw)

|

7.5

|

7.5

|

7.5

|

|

Weight(kg)

|

1350

|

1500

|

2300

|

Raw materials

Shisha coal automatic tablet pressing function will be all kinds of powder materials pressed into circular pieces, square and other special-shaped pieces; Mainly used in the production of shisha charcoal.It can also be used in pharmaceutical, food, coal, chemical, metallurgy, building materials, resistant materials and other industries. Various types of dry and wet powdered granular materials can be pressed into circular pieces or other shapes.

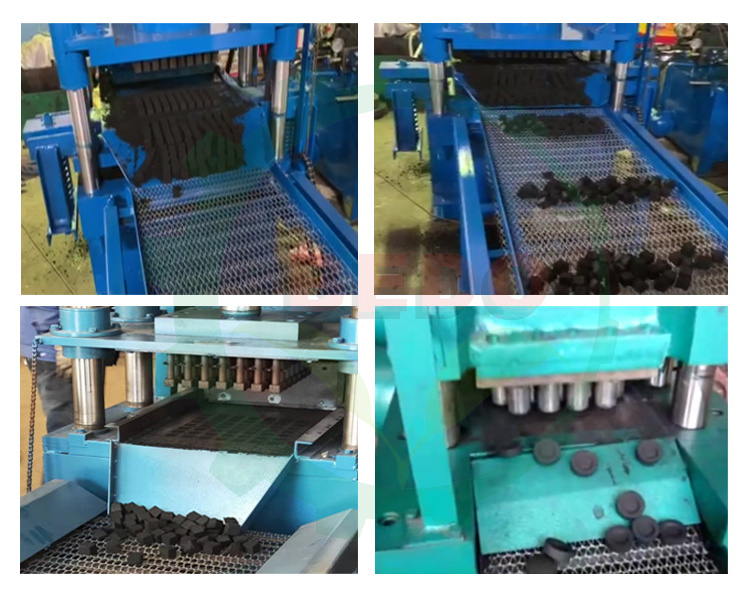

Final Production

Shisha charcoal sheet machine when changing the mold can press the material into sheet (ф 15-ф 50mm) square, rectangular, annular,rhomboid, triangle, cylinder, capsule, cone, convex, concave and other various geometric shape of the product, can also press with text, trademark, pattern, double color, three layers of three colors and various special-shaped. Stamping 40 times per minute, 9-12 pieces per time, about 30,000 pieces per hour.Mainly used in the production of shisha charcoal. It can also be used in pharmaceutical, food, coal, chemical, metallurgy, building materials, resistant materials and other industries. Various types of dry and wet powdered granular materials can be pressed into circular pieces or other shapes.

The production line

Characteristics of carbon powder tablet forming machine:

1. This machine is suitable for pressing tablets with large diameter and large filling amount.

2. New type of forced feeder, can suppress the light weight of charcoal powder, small density of pure powder materials.

3. Newly designed auxiliary equipment, can realize automatic feeding, automatic chip.

4. Humanized design makes the machine easier to clean and maintain.

5. The transmission system is closed in the worm gear box below the main body, which is completely separated parts. It will not pollute each other, but also make the transmission pair fully lubricated to reduce noise and wear. 6. The new installation structure is convenient and fast for the replacement and maintenance of the down punching rail guide and the down pressing wheel.

1. This machine is suitable for pressing tablets with large diameter and large filling amount.

2. New type of forced feeder, can suppress the light weight of charcoal powder, small density of pure powder materials.

3. Newly designed auxiliary equipment, can realize automatic feeding, automatic chip.

4. Humanized design makes the machine easier to clean and maintain.

5. The transmission system is closed in the worm gear box below the main body, which is completely separated parts. It will not pollute each other, but also make the transmission pair fully lubricated to reduce noise and wear. 6. The new installation structure is convenient and fast for the replacement and maintenance of the down punching rail guide and the down pressing wheel.

Packing & Delivery

1. Packing:Standard wooden case.

2. Delivery time: Within 15 workdays after getting the down payment.

3. Payment: 50%TT payment in advance, 50%TT pay the balance before delivery.

4. Warranty: One year.

2. Delivery time: Within 15 workdays after getting the down payment.

3. Payment: 50%TT payment in advance, 50%TT pay the balance before delivery.

4. Warranty: One year.

Hot Searches