- Product Details

- {{item.text}}

Quick Details

-

Air flow (CMH):

-

2000~3000

-

Power consumption (W):

-

210

-

Application field:

-

industrial machines oil mist - coolant mist, water mist and oil mist

-

Certification:

-

ISO9001, CE, ROHS

-

Removal efficient:

-

Over 95%

-

Collection plates:

-

anti-corrosion aluminum alloy sheet

-

OEM/ODM Service:

-

Provided

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Online support

Quick Details

-

Place of Origin:

-

China

-

Weight (KG):

-

150 kg

-

Product Name:

-

industrial oil moisture

-

Air flow (CMH):

-

2000~3000

-

Power consumption (W):

-

210

-

Application field:

-

industrial machines oil mist - coolant mist, water mist and oil mist

-

Certification:

-

ISO9001, CE, ROHS

-

Removal efficient:

-

Over 95%

-

Collection plates:

-

anti-corrosion aluminum alloy sheet

-

OEM/ODM Service:

-

Provided

-

After Warranty Service:

-

Video technical support

-

After-sales Service Provided:

-

Online support

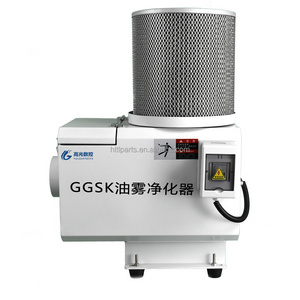

oil mist absorber, oil mist absorber,

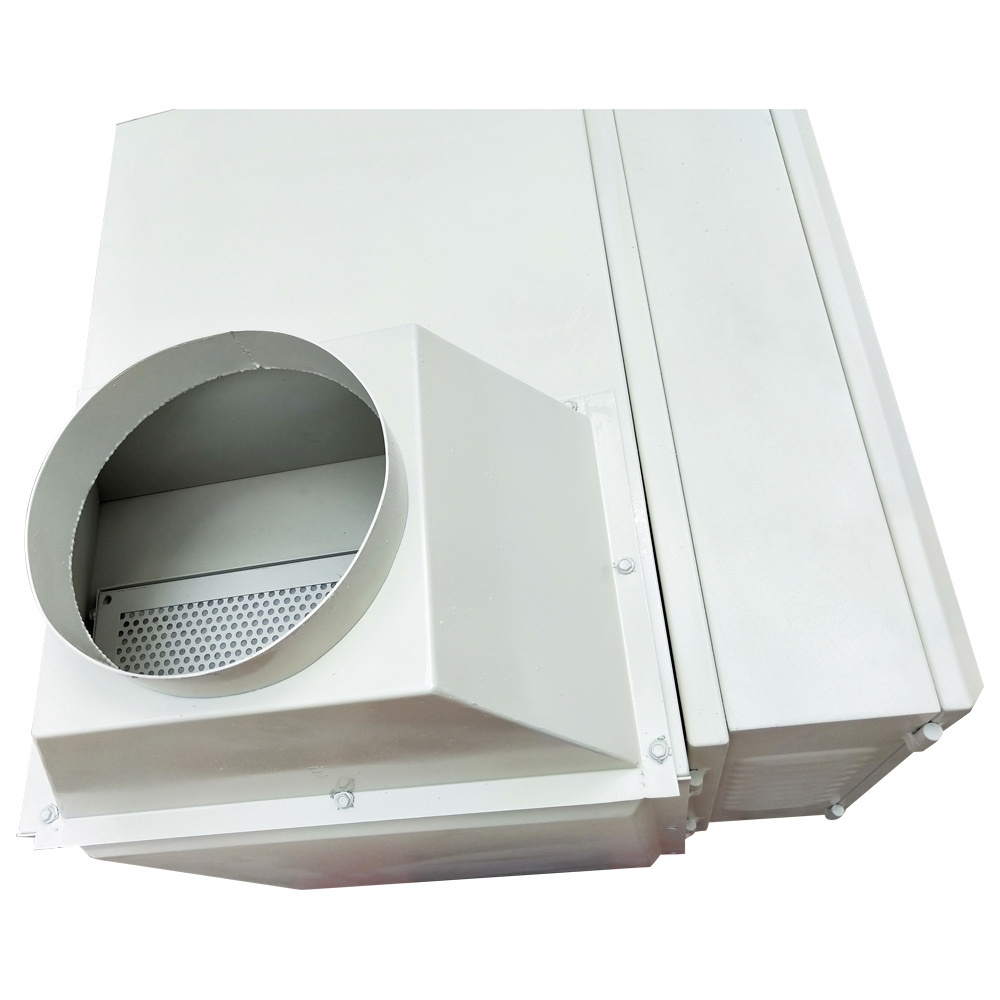

Industrial Electrostatic precipitator ESP / CNC Oil Mist Collectors

Advantages:

Oil mist collector is an excellent choice to remove coolant mist, water mist and oil mist etc. Oil mist are from various processes such as brazing, casting, flame cutting, drilling, grinding, milling and attack.

Benefits:

Maintain high productivity of equipment

Provides a healthy working environment for employee

Collector cell is easy to install, maintain and clean.

Avoid breakdown electrical parts of machines that caused by oil mist.

Certification: ISO9001:2015, CE, ROHS

Supperior features

1. Easy installation, maintenance and cleaning.

2. Intellegent electrostatic power control system.

Electric intensity auto-control function ensures the unit maintains a high purification rate after a long time service.

3. Safety and Stability:

Door-open power-off protection,

Over-current, voltage, temperature protection,

Fan cooling

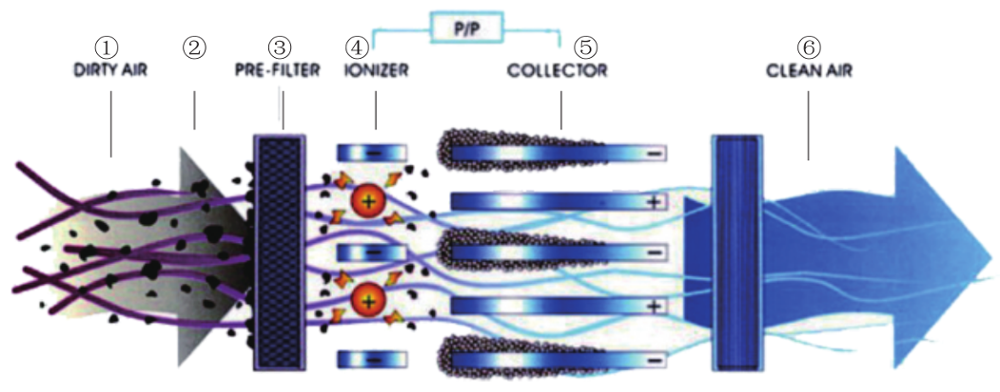

Working principle

1. The dirty air first passes through a pre-filter. Large particles of oil are filtered.

2. The air then passes into the high voltage ioniser section where the particulates are charged to a positive potential.

And then the air passes into low voltage collector cell section where the particulates are charged to a negative potential.

So the particulates are attracted to the collector plates effectively.

3. The particulates remain on the plates or drain down in to the sump.

5. The cleaned air exits through the cabinet.

Intellegent electrostatic power control system

Electric intensity auto-control function ensures the CNC oil mist collectors unit maintains a high purification rate after a long time service.

Installations