Basic principle of fly ash sintered ceramic particles: fly ash mixture, after the

spherical process into spherical particles, under the action of high temperature above 1000 °C, silicon aluminum and other oxides

in fly ash are in a molten state in the particles, and after cooling, ceramic particles light aggregate are formed. Fly ash

sintered ceramic grains completely overcome the powder

The inherent disadvantages of coal ash itself, stable performance (durability).

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

22000, AS CLIENTS REQUIRED

-

Dimension(L*W*H):

-

according to parameter

-

Weight:

-

47500 kg

-

Product name:

-

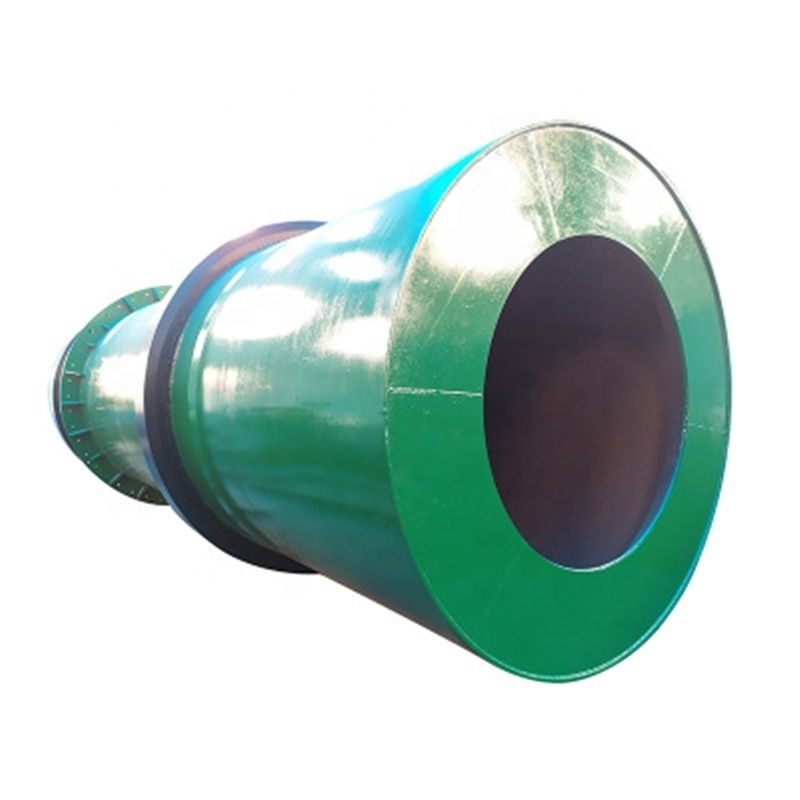

Ceramic Rotary Kiln

-

Application:

-

ceramic production

-

Installation:

-

Engineer Guide

-

Certificate:

-

CE ISO BV

-

Factory visit:

-

welcome

-

After sales service:

-

Our engineers available to serve overseas

-

Usage:

-

Ceramic, lime, cement, mining

-

Keyword:

-

Ceramic Grain Rotary Kiln

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HONGKE

-

Voltage:

-

220v/380v

-

Power:

-

22000, AS CLIENTS REQUIRED

-

Dimension(L*W*H):

-

according to parameter

-

Weight:

-

47500 kg

-

Product name:

-

Ceramic Rotary Kiln

-

Application:

-

ceramic production

-

Installation:

-

Engineer Guide

-

Certificate:

-

CE ISO BV

-

Factory visit:

-

welcome

-

After sales service:

-

Our engineers available to serve overseas

-

Usage:

-

Ceramic, lime, cement, mining

-

Keyword:

-

Ceramic Grain Rotary Kiln

Fly Ash Ceramic Grain Rotary Kiln

Top Brand ceramic rotary kiln system for Sludge, clay, fly ash, mining machinery

The fly ash sintered ceramic granule technology and process equipment adopted have obvious technical advantages in the same industry and similar industries, such as: the fly ash mixing rate in the product > 95%; 90% qualified > finished products; Fly ash has a wide range of applications, no or less binder materials are added to the pelletizing process, product quality is better than national standards, small investment, low cost, high degree of automation, energy saving

and environmental protection, etc., which is the technical guarantee for the comprehensive utilization of fly ash industry to

achieve circular economy and achieve sustainable development. Provide "one-stop service" from process design, equipment manufacturing and supporting, equipment installation and commissioning, product production, ceramic product application technology and later technical support.

and environmental protection, etc., which is the technical guarantee for the comprehensive utilization of fly ash industry to

achieve circular economy and achieve sustainable development. Provide "one-stop service" from process design, equipment manufacturing and supporting, equipment installation and commissioning, product production, ceramic product application technology and later technical support.

Rotary kiln refers to rotary calcining kiln which belongs to building material equipment. According to the material types to be processed, rotary kiln can be divided into bauxite rotary kiln, cement rotary kiln, metallurgical chemistry kiln and lime rotary kiln.

Rotary kiln (cement kiln) is used for making of cement clinker and there are dry and wet methods to make cement.

Rotary kiln (metallurgy chemical) kiln is used for magnetic roasting of iron ore and oxidizing roasting of chrome and nickel in the steel factory. Rotary kiln is used for baking high-alumina mine in the refractory material factory. Rotary kiln is used for baking alumina in the aluminum factory and baking chrome ore and chrome powder in the chemical plant.

Rotary kiln (metallurgy chemical) kiln is used for magnetic roasting of iron ore and oxidizing roasting of chrome and nickel in the steel factory. Rotary kiln is used for baking high-alumina mine in the refractory material factory. Rotary kiln is used for baking alumina in the aluminum factory and baking chrome ore and chrome powder in the chemical plant.

Rotary kiln (lime kilns) is used for baking active lime and dolomite in the steel factory and ferroalloy factory.

Reliable working condition

Temperature can reach 1, 600 to 1, 700 degree Celsius

ISO certificate energy saving bauxite kiln application Rotary kiln is rotary cylinder equipment for burning various materials

Widely used in economic fields

It can be used for drying many kinds of materials limestone slag, coal powder, slag, clay stone

Its highest temperature can reach 1, 600 to 1, 700 degree Celsius

Reliable working condition

Temperature can reach 1, 600 to 1, 700 degree Celsius

ISO certificate energy saving bauxite kiln application Rotary kiln is rotary cylinder equipment for burning various materials

Widely used in economic fields

It can be used for drying many kinds of materials limestone slag, coal powder, slag, clay stone

Its highest temperature can reach 1, 600 to 1, 700 degree Celsius

Working principle

Features and Function of Rotary Kiln

1.Ceramic Sand Rotary Kiln has simple structure, convenient and reliable control during the production process, a few wearing parts, high operation ratio. The rotary kiln produced by our factory has rugged structure, smooth operation, high quality outlet products. Besides, we provide our customers with advanced, efficient vertical heating device, and cyclone heating device.

2.Through technological innovation, our rotary kiln is designed with international leading wheel catch device, high precision plunger metering pump, high accuracy speed control valve and contact graphite block sealing device, etc.

3.In order to improve machinery automation, an industrial computer is used for showing the calcining condition, and a fluorescent screen is adopted for showing the simulated process flows. An infrared scanner is utilized for transmitting the calcining condition to the computer.

These new technologies provide our rotary kiln with strong visual sense, convenient operation and reliable performance. They help stabilize thermal regulation and improve operation efficiency.

2.Through technological innovation, our rotary kiln is designed with international leading wheel catch device, high precision plunger metering pump, high accuracy speed control valve and contact graphite block sealing device, etc.

3.In order to improve machinery automation, an industrial computer is used for showing the calcining condition, and a fluorescent screen is adopted for showing the simulated process flows. An infrared scanner is utilized for transmitting the calcining condition to the computer.

These new technologies provide our rotary kiln with strong visual sense, convenient operation and reliable performance. They help stabilize thermal regulation and improve operation efficiency.

Structure of Rotary Kiln Machine:

1. The Rotary Kiln Machine'sshell is made of rolled steel plates; its structure is optimized by computer software, and features" longitudinal flexible and transverse rigid”, which improved the loading of supporting device and stability of refractory lining.

2. The supporting roller bearings features smaller width over diameter ratio L/D, leading to its higher reliability.

3. The special high-started torque motor for cement industry rotary kiln is applied for driving system.

4. The sealing of labyrinth plus spring pressing with asbestos heat isolation layers attached, is applied higher so that

reliability and longer service life of sealing are achieved.

2. The supporting roller bearings features smaller width over diameter ratio L/D, leading to its higher reliability.

3. The special high-started torque motor for cement industry rotary kiln is applied for driving system.

4. The sealing of labyrinth plus spring pressing with asbestos heat isolation layers attached, is applied higher so that

reliability and longer service life of sealing are achieved.

Rotary Kiln Technical Parameters

|

Specifications

(m) |

Kilndimension

|

|

|

Output(t/h)

|

Rotationspeed(r/min)

|

Motorpower(kw)

|

Weight

|

||

|

|

Diameter(m)

|

Length(m)

|

Slope(%)

|

|

|

|

(t)

|

||

|

Ø1.4*33

|

1.4

|

33

|

3

|

0.9-1.3

|

0.39-3.96

|

18.5

|

47.5

|

||

|

Ø1.6*36

|

1.6

|

36

|

4

|

1.2-1.9

|

0.26-2.63

|

22

|

52

|

||

|

Ø1.8*45

|

1.8

|

45

|

4

|

1.9-2.4

|

0.16-1.62

|

30

|

78.2

|

||

|

Ø1.9*39

|

1.9

|

39

|

4

|

1.65-3

|

0.29-2.93

|

30

|

77.59

|

||

|

Ø2.0*40

|

2

|

40

|

3

|

2.5-4

|

0.23-2.26

|

37

|

119.1

|

||

|

Ø2.2*45

|

2.2

|

45

|

3.5

|

3.4-5.4

|

0.21-2.44

|

45

|

128.3

|

||

|

Ø2.2*60

|

2.2

|

60

|

3.5

|

6.0-8.0

|

0.44-2.44

|

50

|

150.2

|

||

|

Ø2.5*40

|

2.5

|

40

|

3.5

|

9.0-10.5

|

0.44-2.44

|

55

|

149.61

|

||

|

Ø2.5*50

|

2.5

|

50

|

3

|

6.25-7.4

|

0.62-1.86

|

55

|

187.37

|

||

|

Ø2.5*60

|

2.5

|

60

|

3.5

|

10.0-12.5

|

0.44-1.2

|

55

|

199.2

|

||

|

Ø2.5*54

|

2.5

|

54

|

3.5

|

6.9-8.5

|

0.48-1.45

|

55

|

196.29

|

||

|

Ø2.7*42

|

2.7

|

42

|

3.5

|

10-11

|

0.10-1.52

|

55

|

198.5

|

||

|

Ø2.8*44

|

2.8

|

44

|

3.5

|

12.5-13.5

|

0.437-2.18

|

55

|

201.58

|

||

|

Ø3.0*45

|

3

|

45

|

3.5

|

12.8-14.5

|

0.5-2.47

|

100

|

210.94

|

||

|

Ø3.0*48

|

3

|

48

|

3.5

|

25.6-29.3

|

0.6-3.48

|

100

|

237

|

||

|

Ø3.0*60

|

3

|

60

|

3.5

|

12.3-14.1

|

0.3-2

|

100

|

310

|

||

|

Ø3.2*50

|

3.2

|

50

|

3.5

|

40.5-42

|

0.6-3

|

160

|

278

|

||

|

Ø3.5*52.5

|

3.5

|

52.5

|

3.5

|

42-43.5

|

0.6-3.6

|

180

|

366

|

||

FAQ:

In order to find the suitable models and design the best dryer for you, pls kindly inform us the following information:

1. Could you give me the detailed analysis of the raw materials?

2. What is your required capacity(t/d)?

3. Waht is the fuel, gas or oil or coal pls?

4. Do you haveany other special requirement pls?

Our engineers will suggest you the most suitable one for you according to your information.

We will give you factory pricewith full specification, so pls leave us an inquiry to know more details about price, packaging

shipping and discount.

1. Could you give me the detailed analysis of the raw materials?

2. What is your required capacity(t/d)?

3. Waht is the fuel, gas or oil or coal pls?

4. Do you haveany other special requirement pls?

Our engineers will suggest you the most suitable one for you according to your information.

We will give you factory pricewith full specification, so pls leave us an inquiry to know more details about price, packaging

shipping and discount.

Company Introduction

Aerial view of the factory

Factory photo taken

Factory workshop actual photos

⭐

About US

⭐

Henan Hongke Heavy Machinery Cp,,Ltd is a research and development, production and sales in one professional group,It is the rapid rise dazzling star in machinery industry by the economy development of China

We are specialized in grinding, crushing, drying,rotary kiln product development and production of high-tech enterprises, including lime kiln State Environment Protection Agency recommended products.The company developed the Raymond mill, ulyrafine mill, dryer, rotary kiln, series crusher,stone crusher, vibrating screen series, jaw crusher, hammer crusher, impact crusher, cone crusher, Sand and gravel production line—— ( sand production line), and other devices with the leading domestic level, some products have reached the international advanced level.Two years of wind and rain entrepreneurship, Acer Branch who never gave up.Full cast Plains, the company brings together a large number of innovation, on behalf of the national level of the industry's outstanding scientific research and management personnel, created a unity march, strict and efficient workforce.To meet the business development and market competition, the company has built a first-class modern production and testing base, nationwide sales network,the company early ten thousand users to provide good services. Companies adhere to the " Industrial quality" start thinking of pursing a "customer satisfaction" principle of service to "good faith,seek truth from facts"for the operation of the country. Won the " quality of the letter units" and other honorary title, " wang section" trademark has become a kiln, a symbol of the mill product credibility."Product quality is the life", the company to modern management , better technology, advanced production equipment and strict means testing, introduced various types of high-quality industrial rotary kiln , milling machines and dryers and other products. The company will continue to hold high the Industrial serve the country, the conomic revitalization of the Chinese nation," the banner, dedication and four Haibin friends and create brilliant, jointly hold the Chinese solar industry.Henan Hongke Heavy Industry Machinery Equipment Co., Ltd. is a group company integrating scientific research, production and marketing, and is a dazzling star in China's machinery industry with the rapid rise of market economy. For more than ten years, Hongke people have been self-improvement and forged in the Central Plains.

The company has brought together a large number of scientific research and management talents who are determined to innovate and represent the level of the industry, creating a united and forging ahead and strict staff. The company has established rotary kiln production line, Raymond mill, dryer, sand making machine, ball mill, pre-crusher and other production lines. In order to meet the needs of enterprise development and market competition, the company has built a modern production base: covering the domestic sales and service network, providing thoughtful services for nearly 10,000 users of the company.

Advantages of Our Factory:

1) Has almost 20 years experience

2) Owning the biggest workshop and advanced equipments in the industry

3) Strict management and good prestige

Advantages of Our Equipments:

1) Advance technics and standard testing

2) Strict quality control system

3) Have passed ISO9001: 2000 international quality certification

4) Preferential price

Advantages of Our Service:

1) Perfect service after sale

2) Design and build factory, install and run equipments, and train workers freely for our customer

3) Quality guarantee for 1 year's time, providing spare parts at cheap price

1) Has almost 20 years experience

2) Owning the biggest workshop and advanced equipments in the industry

3) Strict management and good prestige

Advantages of Our Equipments:

1) Advance technics and standard testing

2) Strict quality control system

3) Have passed ISO9001: 2000 international quality certification

4) Preferential price

Advantages of Our Service:

1) Perfect service after sale

2) Design and build factory, install and run equipments, and train workers freely for our customer

3) Quality guarantee for 1 year's time, providing spare parts at cheap price

Reasons to choose Hongke machines

1.Self-produced and self-sold, guaranteed after-sales, one-stop service allows you to buy machinery safely

2.Online customer service

3.Specialized in transporting equipment

4.Private car transfer for field trips

5.Dedicated technical guidance training

6.Professionally tailor-made solutions

7.Exclusive after-sales service system

1.Self-produced and self-sold, guaranteed after-sales, one-stop service allows you to buy machinery safely

2.Online customer service

3.Specialized in transporting equipment

4.Private car transfer for field trips

5.Dedicated technical guidance training

6.Professionally tailor-made solutions

7.Exclusive after-sales service system

Why Choose Us

To Be Your Satisfied Partner

We provide not only quality products, But solution for full set equipment!

Some Cooperated Foreign Customers

By spirit of perseverance, We will try our best to provide more new products and technical support to customers from home and abroad.

By product absolutely advantages and excellent service team

and first-class service system, Hongke has won great honors of customer form home and abroad.

Hot Searches