- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

50 mm

-

Power (kW):

-

5.5 kW

-

Weight (KG):

-

1250 KG

-

Place of Origin:

-

China

-

Product name:

-

Electric shearing machine

-

Travel times:

-

13 times/min

-

Cutting angle:

-

1 30'

-

Cutting thickness:

-

3mm

-

Backgauge range:

-

20-500mm

-

Application:

-

Industrial Metal Cutting

-

Cutting material:

-

Metal .alloy Metal .aluminum

-

Control system:

-

Delem

-

Cutting mode:

-

Electric

-

Keyword:

-

Metal Steel Cnc Cutting Machine

Quick Details

-

Max. Cutting Width (mm):

-

2000

-

Max. Cutting Thickness (mm):

-

3 mm

-

Blade Length (mm):

-

2000 mm

-

Throat Depth (mm):

-

50 mm

-

Power (kW):

-

5.5 kW

-

Weight (KG):

-

1250 KG

-

Place of Origin:

-

China

-

Product name:

-

Electric shearing machine

-

Travel times:

-

13 times/min

-

Cutting angle:

-

1 30'

-

Cutting thickness:

-

3mm

-

Backgauge range:

-

20-500mm

-

Application:

-

Industrial Metal Cutting

-

Cutting material:

-

Metal .alloy Metal .aluminum

-

Control system:

-

Delem

-

Cutting mode:

-

Electric

-

Keyword:

-

Metal Steel Cnc Cutting Machine

Products Description

Instruction for Metal Steel Sheet Cutting Shearing Machine

Q11 mechanical shearing machine has simple structure, easy operation, elegant design, attractive appearance and low energy consumption. Mechanical shears Uses resist key structural form and open gear clutch transmission, and more advanced Electric operation (foot switch, manual switch) with low noise operation and easy maintenance. It is widely used in metallurgy, light industry, machinery, hardware, electrical, electronics, automotive repair, metal fabrication and other sheet metal processing industry.

Instruction for Metal Steel Sheet Cutting Shearing Machine

Q11 mechanical shearing machine has simple structure, easy operation, elegant design, attractive appearance and low energy consumption. Mechanical shears Uses resist key structural form and open gear clutch transmission, and more advanced Electric operation (foot switch, manual switch) with low noise operation and easy maintenance. It is widely used in metallurgy, light industry, machinery, hardware, electrical, electronics, automotive repair, metal fabrication and other sheet metal processing industry.

Features for Metal Steel Sheet Cutting Shearing Machine

1. the whole machine body uses the integrally weld structure, ensuring the high strength and good rigidity of the machine.

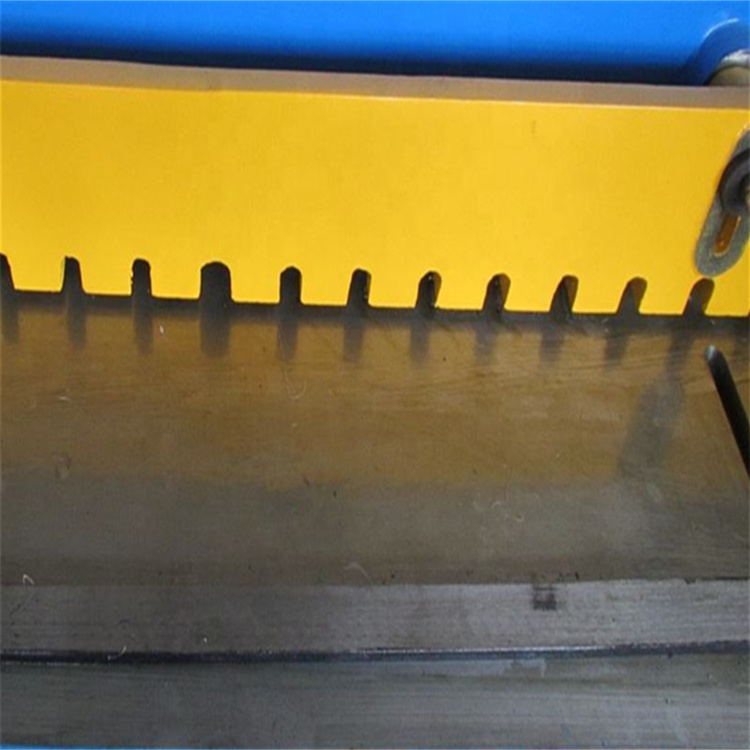

2.shearing blade uses Cr2 material, ensuring the good performance and long performance life.

3. the structure of the machine is simple, easy operation and low consumption.

2.shearing blade uses Cr2 material, ensuring the good performance and long performance life.

3. the structure of the machine is simple, easy operation and low consumption.

Equipment:

1. Rapid and precise blade clearance adjustment by single handle on the side frame

2. Multi Edge Blades for cutting Aluminium, Mild Steel and Stainless Steel

3. Cutting Line Illumination and wire for shadow line cutting

4. Counter of Strokes, Cutting Length Adjustment

5. Hydraulic and Electrical overload protection

6. Squaring Arm and Front Support Arms

7. MD11 control

8. Germany Bosch-Rexroth Hydraulic

9. Telemecanique/SchneiderElectrics

10. Hydraulic and Electrical overload protection

11. Delta inverter with ball screw and polished rod with 0,05 mm accuracy.

12. Side guard is standard meeting CE regulations.

Better Cuttings:

1.Backgauge adjustment according to blade gap.

2.Backgauge retraction feature.

3.Sub-program and programming loop.

4.Sequence repeat function.

5.Auto cutting

1. Rapid and precise blade clearance adjustment by single handle on the side frame

2. Multi Edge Blades for cutting Aluminium, Mild Steel and Stainless Steel

3. Cutting Line Illumination and wire for shadow line cutting

4. Counter of Strokes, Cutting Length Adjustment

5. Hydraulic and Electrical overload protection

6. Squaring Arm and Front Support Arms

7. MD11 control

8. Germany Bosch-Rexroth Hydraulic

9. Telemecanique/SchneiderElectrics

10. Hydraulic and Electrical overload protection

11. Delta inverter with ball screw and polished rod with 0,05 mm accuracy.

12. Side guard is standard meeting CE regulations.

Better Cuttings:

1.Backgauge adjustment according to blade gap.

2.Backgauge retraction feature.

3.Sub-program and programming loop.

4.Sequence repeat function.

5.Auto cutting

Specification

|

Model

|

Max.width (mm)

|

Max.thickness (mm)

|

|

Q11-1.5x1300

|

1300

|

1.5

|

|

Q11-1.5X2000

|

2000

|

1.5

|

|

Q11-2.0x1300

|

1300

|

2.0

|

|

Q11-2.0x2000

|

2000

|

2.0

|

|

Q11-3.0x1300

|

1300

|

3.0

|

|

Q11-3.0x2000

|

2000

|

3.0

|

|

Q11-4.0x1300

|

1300

|

4.0

|

|

Q11-4.0x2000

|

2000

|

4.0

|

Packaging & Shipping

Why Choose Us

Hot Searches