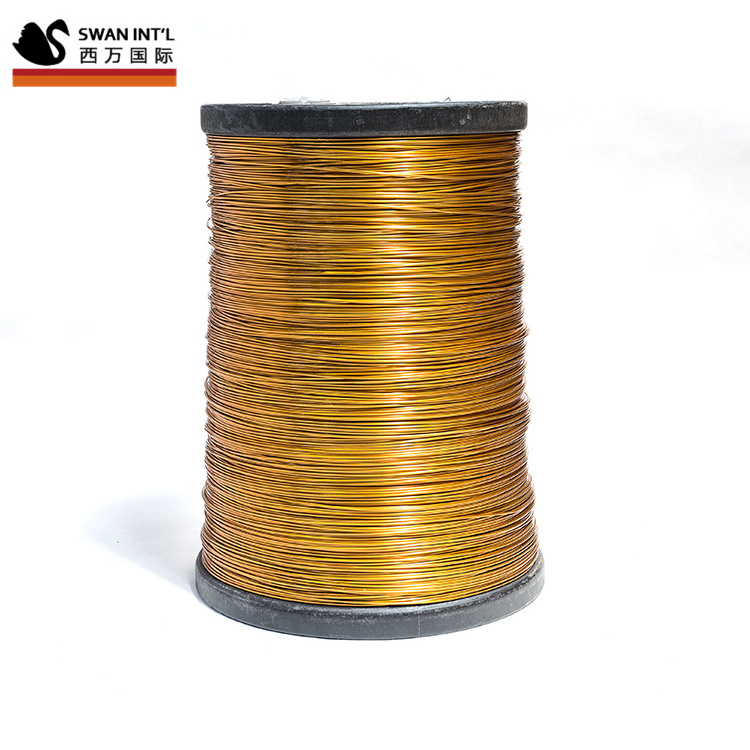

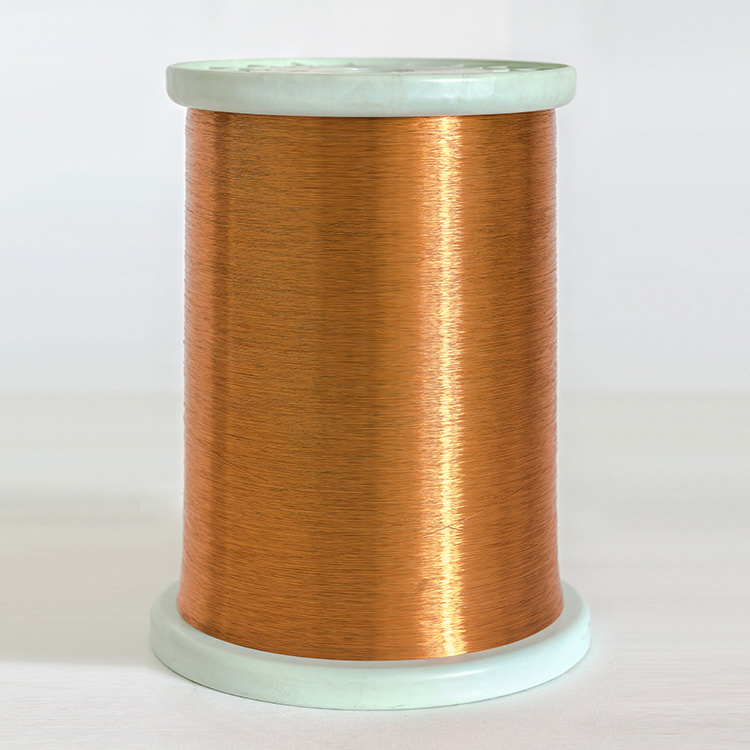

This product provides high heat resistance,high cut through,solvent resistance,cold resistance,freon resistance,etc. UL certificated,file number E250244

Application Field

Suitable for coil -immersed

transformers ,dry-type transformers,high-temperature transformers.rerigeration compressor motors,sealed motors,explpsion*-proof motors,electric tools motors,solenoids,and high-power motors,etc