- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

3k

-

Weight:

-

1800 KG

-

Dimension(L*W*H):

-

2200*600*900mm

-

Year:

-

2022

-

Name:

-

Tomato Paste Production Line

-

Raw material:

-

304 Sainless Steel

-

Capacity:

-

300~1000kg/h

-

Key words:

-

high productivity

Quick Details

-

Place of Origin:

-

SHG

-

Brand Name:

-

Chenwei

-

Type:

-

food machine

-

Voltage:

-

220V/380V

-

Power:

-

3k

-

Weight:

-

1800 KG

-

Dimension(L*W*H):

-

2200*600*900mm

-

Year:

-

2022

-

Name:

-

Tomato Paste Production Line

-

Raw material:

-

304 Sainless Steel

-

Capacity:

-

300~1000kg/h

-

Key words:

-

high productivity

Product Parameters

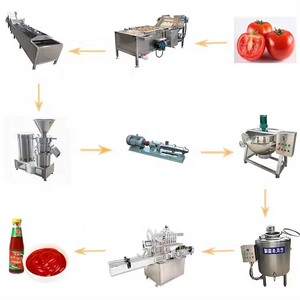

Introduction of tomato paste production line :

The production line include lifting system, cleaning system, sorting system, crushing system, preheating enzyme sterilization system, beating system, vacuum, concentration system, sterilization system and aseptic bag filling system, including lifting system, cleaning system, sorting.

The whole line can process concentrated fruit and vegetable products such as strawberry jam, blackberry jam, blueberry jam, raspberry jam, apple jam, mango jam, apricot jam, carrot jam, onion jam and chili jam.

The whole line can process concentrated fruit and vegetable products such as strawberry jam, blackberry jam, blueberry jam, raspberry jam, apple jam, mango jam, apricot jam, carrot jam, onion jam and chili jam.

We can customized capacity and p

roduction line configuration according customer's requirements.

Fresh tomato processing line

The processing equipment includes fresh fruit cleaning machine, crushing machine, filter and enzyme sterilizer. The whole project is connected by pipeline and lifting system for automatic processing, and can process a variety of fruits.

It can be customized according to customer requirements.

Our strengths:

*It can be designed according to the special requirements of users

*Multiple products can be produced on the same production line

*It can produce high quality products and keep nutrients

*Aromatic substances can be added and mixed precisely

*Extend the shelf life of products

*Large output and small loss

*Application of high technology to save energy consumption

*According to the customer's choice, we can provide a variety of drink configuration.

*Drink type, packaging type and automation degree can be matched at will according to customer requirements.

*It can be designed according to the special requirements of users

*Multiple products can be produced on the same production line

*It can produce high quality products and keep nutrients

*Aromatic substances can be added and mixed precisely

*Extend the shelf life of products

*Large output and small loss

*Application of high technology to save energy consumption

*According to the customer's choice, we can provide a variety of drink configuration.

*Drink type, packaging type and automation degree can be matched at will according to customer requirements.

|

Raw material

|

Fresh tomato

|

|

|

|

|||

|

Final products

|

Tomato paste/ ketchup

|

|

|

|

|||

|

Products packaging

|

Plastic bottle ,cans, pouch

|

|

|

|

|||

|

Capacity

|

100-3000kg/H

|

|

|

|

|||

|

Plant area required

|

200-1500㎡

|

|

|

|

|||

|

Loss rate

|

Not more than 3%

|

|

|

|

|||

|

Equipment production cycle

|

About 40 days

|

|

|

|

|||

Product Display

Related Products

Hot Searches