a.Functional Configuration:

The worker put coil on the decoiler,

and tensioning it through spanner

b.Technical parameters:

The maximum load capacity : 5 tons

Suitable coil width: 1220

- Product Details

- {{item.text}}

Quick Details

-

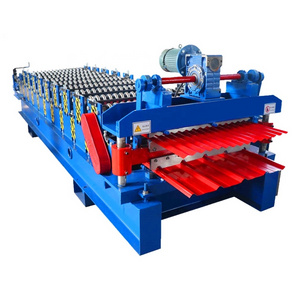

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Brand Name:

-

CHENGLANG/PUTAI

-

Voltage:

-

380V 50HZ 3 PHASE

-

Weight:

-

2300 kg

-

Usage:

-

Roof Tile Panel

-

Cutting blade material:

-

Cr12

-

Shaft material:

-

High Grade 45# Forged Steel

-

Roller material:

-

High Grade 45# Forged Steel

-

Produce speed:

-

20-25m/min

-

Product name:

-

Roof Sheet Forming Machine

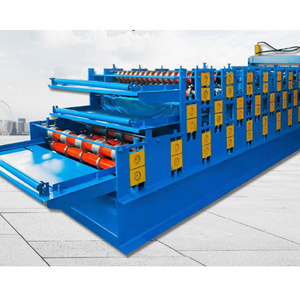

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

25 sets per month

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

China

-

Brand Name:

-

CHENGLANG/PUTAI

-

Voltage:

-

380V 50HZ 3 PHASE

-

Weight:

-

2300 kg

-

Usage:

-

Roof Tile Panel

-

Cutting blade material:

-

Cr12

-

Shaft material:

-

High Grade 45# Forged Steel

-

Roller material:

-

High Grade 45# Forged Steel

-

Produce speed:

-

20-25m/min

-

Product name:

-

Roof Sheet Forming Machine

Product Description

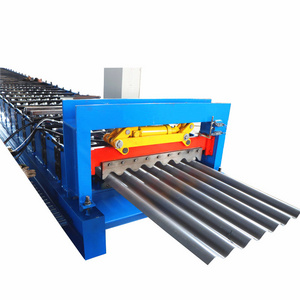

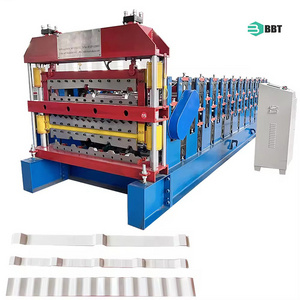

Roofing Sheet Corrugating Iron Sheet Roll Forming Making Machine

Decoiler

a.Material:high grade 45# forged steel

b.Surface 0.05mm hard chrome coating

c.Polishing

d.Longer service life

a.Material:high grade 45# forged steel

b.our shaft is solid shaft

c.high precision for roof panel

a.motor with good quality and being powerful

b.depends on the different profile

drawing,use different power motor

c.fixed at the bottom of the frame or beside

the frame

a.Delta Brand from Taiwan to ensure high speed,

with stability, precision and lifetime.

b.Other electric element are Panasonic

c.input the speed, length, and pcs, it will

control machine working automaticly.

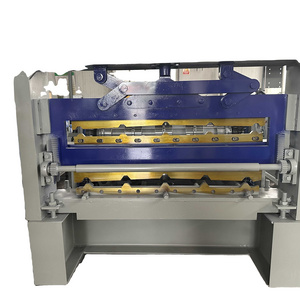

Blade cutting system

a.Blade Material:Cr12

b.Heat treatment

c.Thick, high wear-resisting knife plate

d.Hydraulic pillar guide cutting

Hydraulic system

a. The main valve parts adopt domestic

high-quality brand.

b. Oil cylinder and oil pump adopt national standard

rod oil cylinder, easy to purchase all over the world.

c. The motor is national standard copper core,

universal around the world.

d. 5.5KW

Output table

c. Material:square steel pipe welded

Related Products

Packing&Shipping

1). Tighten to container with steel wire rope and welded machine with container by angel iron

2). Main forming machine and

un-coiler is naked(If you need we can also packed with water-proof plastic)

3). PLC contral system and motor pump are packed in

box with water proof paper coverage

box with water proof paper coverage

Transported By 40ft container

Company Introduction

Our Facotry has 25 years in ceiling frame filed. Product quality is stable,high cost performance,excellent design engineers and good processing technology to ensure the quality of the equipment and performance,and passed the quality system certification,has a complete and scientific quality management system.Its design and production of the product not only best-selling domestic,but also exported to southeast Asia,the Middle east,South America,North America,Europe and other countries and regions,has own widespread praise and high praise!

Company main products: C/U steel forming machine, Ceiling T grid forming machine and Light steel keel packing machine and all kinds of cold bending processing customized special equipment,etc.The company is located in Tianjin,The traffic is very convenient.We insist on quality as the root,the prestige for this service principle,Our all the staff welcome you to come to discuss cooperation !

FAQ

1-Are you manufacturer or trading company?

Yes, and we have more than 25 years

2-Can the machine parts be changed according to my requirements?

Yes, we will try our best to give you the best products.

3-What is your payment term?

30% TT deposit paid in advance, 70% balance paid before shipping.

4-What is the delivery time?

About 35days after receive the deposit.

5- How can I get to your factory?

We could pick you up in airport or high speed rail station. The nearest airport is Beijing Daxing airport or Tianjin airport, and the nearest station is Bazhou or Shengfang station,please contact us.

6- What service can you provide before order?

About the pre-sale service. We provide you answers of all your questions on our machines, such as technical parameter, price, payment terms, ect. If you wanna visit our factory and check the machines, we also can send you invitation letter and give you our warmest welcome.

7- Can you finish the machine during the delivery time?

We will finish the machine in time according to determined lead time

8- Can you provide some spare parts?

Yes. The quick-wear parts are sent to you together with the machine

Hot Searches