- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

4

-

Weight (KG):

-

3300

-

Product name:

-

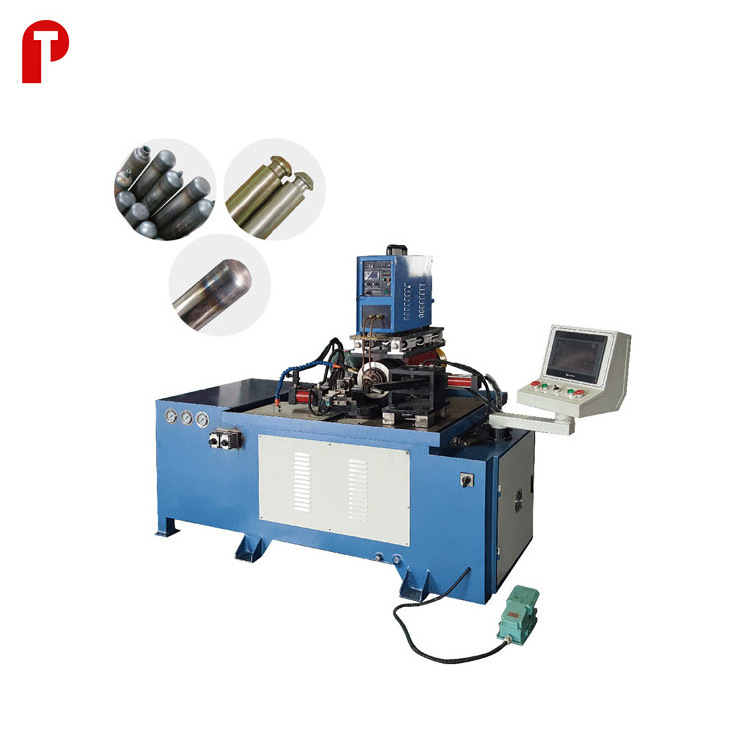

Tube end forming machine

-

Model:

-

TF-50

-

Function:

-

tube end reducer

-

Certification:

-

CE ISO, ce

-

Color:

-

Blue

-

Voltage:

-

380V/50HZ/Customized

-

Power:

-

4KW

-

Dimension:

-

1990*1200*1250mm

-

Keyword:

-

tube end machine

-

After-sales Service Provided:

-

Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

Quick Details

-

Max.Shrinking Capacity (Thickness)(mm):

-

2.5 mm

-

Max.Shrinking Capacity (Diameter)(mm):

-

60 mm

-

Place of Origin:

-

China

-

Power (kW):

-

4

-

Weight (KG):

-

3300

-

Product name:

-

Tube end forming machine

-

Model:

-

TF-50

-

Function:

-

tube end reducer

-

Certification:

-

CE ISO, ce

-

Color:

-

Blue

-

Voltage:

-

380V/50HZ/Customized

-

Power:

-

4KW

-

Dimension:

-

1990*1200*1250mm

-

Keyword:

-

tube end machine

-

After-sales Service Provided:

-

Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service, Video technical support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

Product Description

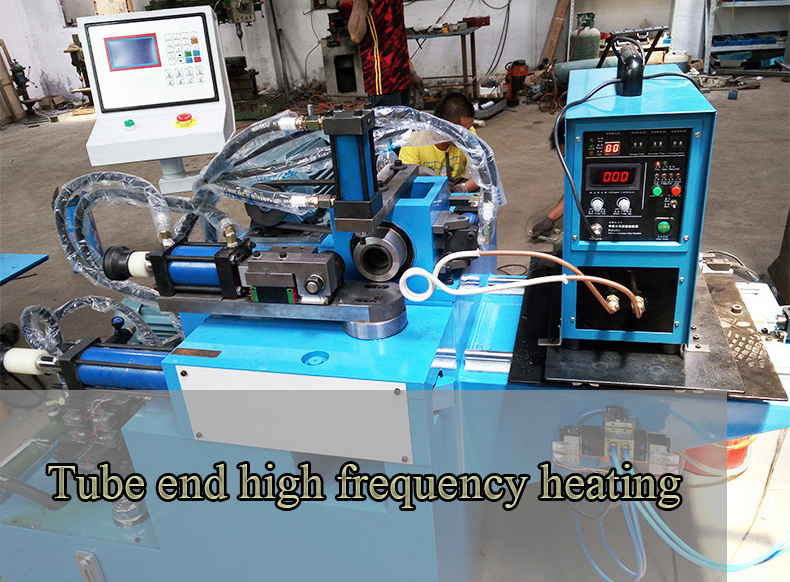

The machine is a special equipment for the processing of the copper pipe end, which can make the copper pipe end processing into a horn type, sealing and the like.

The machine processes one copper tube at a time, and the commonly used copper tube is 12~25mm.

With manual and single automatic mound function.

The machine processes one copper tube at a time, and the commonly used copper tube is 12~25mm.

With manual and single automatic mound function.

The single cycle sequence of the whole machine is: manual feeding----clamping---positioning block avoiding---sealing---flare cylinder back

Retract the clamping cylinder - the positioning block is reset and unloaded.

The effective size of the processed copper tube is positioned by the cylinder and manually loaded and unloaded.

The whole machine is controlled by PLC, which is easy and convenient to operate. With emergency stop and counting function. With foot switch.

Retract the clamping cylinder - the positioning block is reset and unloaded.

The effective size of the processed copper tube is positioned by the cylinder and manually loaded and unloaded.

The whole machine is controlled by PLC, which is easy and convenient to operate. With emergency stop and counting function. With foot switch.

Specification

|

Diameters

|

φ12 --φ25 cooper

|

|

Thickness

|

1-2.5mm

|

|

Forming station

|

1

|

|

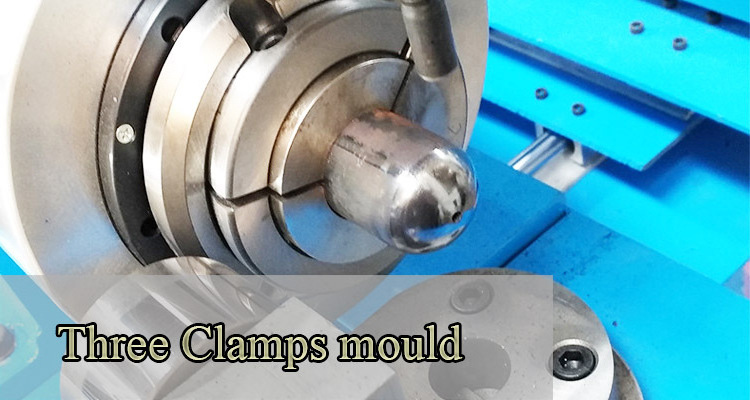

Clamp

|

Hydraulic air core rotation

|

|

Forming method

|

Cold forming

|

|

Main motor

|

4KW

|

|

Clamp press

|

3300kg

|

|

X speed

|

200mm-300 mm

|

|

X .Y percision

|

±0.05

|

|

Y speed

|

100mm 150 mm

|

|

Power

|

380V(Customized)

|

Relatived tube end forming machine processing for different shapes for tube end forming.

Product packaging

Packaging:

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like

to have seamless cooperation with your forwarder at your convenience.

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like

to have seamless cooperation with your forwarder at your convenience.

Hot Searches