- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

5016*41170*3722mm

-

Weight:

-

6850 KG

-

Marketing Type:

-

Hot Product

-

type:

-

gold cip production line

-

gold recovery rate:

-

99%

-

Capacity:

-

5-2000t/h

-

Usage:

-

Separate Gold

-

Product name:

-

gold ore mining equipment and dressing plant

-

Application:

-

Gold

-

Feeding size:

-

0-30mm

-

Color:

-

Customized Color

-

Installation:

-

Engineer Guidance

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Production Capacity:

-

98.2%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Xinhai

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

5016*41170*3722mm

-

Weight:

-

6850 KG

-

Marketing Type:

-

Hot Product

-

type:

-

gold cip production line

-

gold recovery rate:

-

99%

-

Capacity:

-

5-2000t/h

-

Usage:

-

Separate Gold

-

Product name:

-

gold ore mining equipment and dressing plant

-

Application:

-

Gold

-

Feeding size:

-

0-30mm

-

Color:

-

Customized Color

-

Installation:

-

Engineer Guidance

-

After-sales Service Provided:

-

Field installation, commissioning and training

Note

:This is not our real price, please consult our sales to get the specific price!

Strive to Provide the Optimized Solutions for Your Mine!

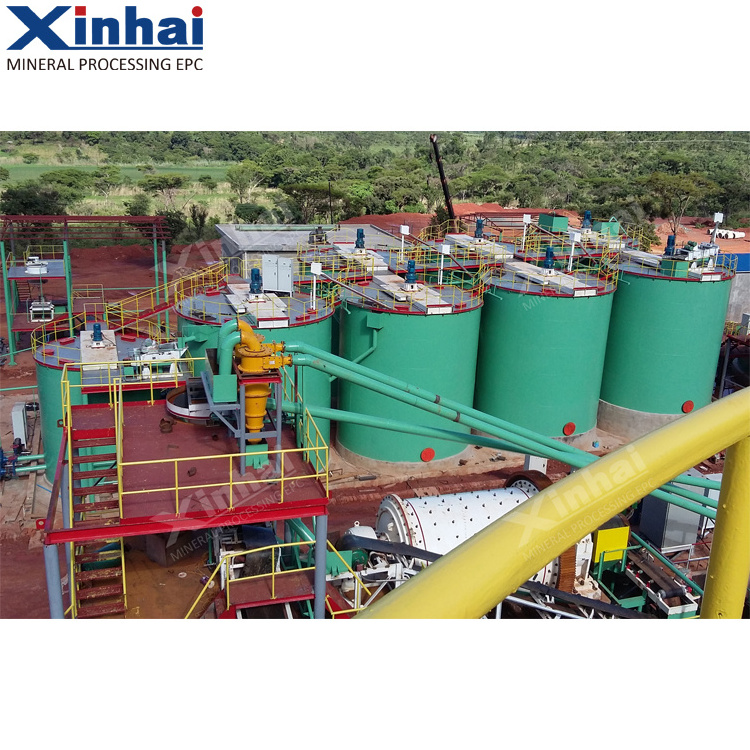

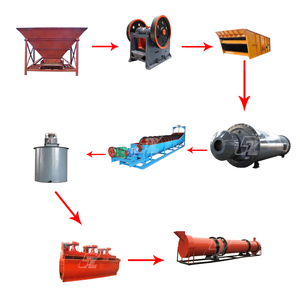

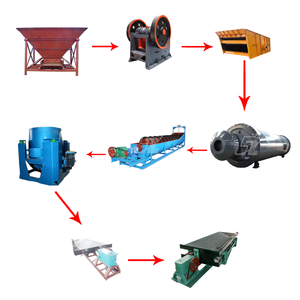

The introduction of gold processing plant

Gold CIP process adsorbs gold from cyaniding pulp by active carbon including 7 steps:

leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit,carbon acid regeneration, and leaching pulp.

leaching pulp preparation, cyaniding leaching, carbon adsorption, gold loaded carbon desorption, pregnant solution electrodeposit,carbon acid regeneration, and leaching pulp.

|

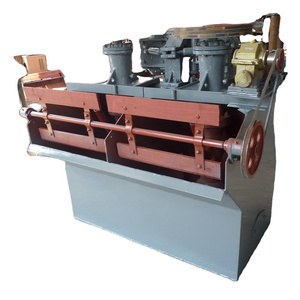

The advantage of

gold electrolysis system

|

|

Under the high temperature and pressure, the desorption electrolysis system has advantages of low cyanide, automatic controlling, high efficiency, fast and low energy consumption.

|

Intelligent equipment manufacturing:

Xinhai has an automation equipment research, development and production base, which can produce intelligent mineral processing equipment with sensors, and can optimize and upgrade the control systems of key links such as grinding, flotation, and concentration.

Xinhai has an automation equipment research, development and production base, which can produce intelligent mineral processing equipment with sensors, and can optimize and upgrade the control systems of key links such as grinding, flotation, and concentration.

IoT management and control platform

Based on the Internet of Things technology, Xinhai builds an intelligent processing plant management and control platform to realize the data collection, transmission, integrated use, big data analysis and processing of the entire concentrator, and intelligently manage and control the personnel, equipment, materials, energy, logistics of the enterprise.

Based on the Internet of Things technology, Xinhai builds an intelligent processing plant management and control platform to realize the data collection, transmission, integrated use, big data analysis and processing of the entire concentrator, and intelligently manage and control the personnel, equipment, materials, energy, logistics of the enterprise.

Concentrator automation management

With the close combination of automation system and the concentrator, Xinhai collects, monitors and analyzes production data, and realizes centralized control of the concentrator

equipment at the same time. There is also a large-screen display system for displaying video surveillance images and DCS process flow images.

With the close combination of automation system and the concentrator, Xinhai collects, monitors and analyzes production data, and realizes centralized control of the concentrator

equipment at the same time. There is also a large-screen display system for displaying video surveillance images and DCS process flow images.

Automation system design:

Xinhai can coordinate and optimize the control of crushing, grinding, separation, concentrate dewatering, tailings transportation, water system and other links in the dressing process, so as to realize the design of the whole process automation system of the concentrator.

Xinhai can coordinate and optimize the control of crushing, grinding, separation, concentrate dewatering, tailings transportation, water system and other links in the dressing process, so as to realize the design of the whole process automation system of the concentrator.

Hot Searches