X1+X2+R1+R2+Z1+Z2

- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

250 mm

-

Width of Working Table (mm):

-

1600 mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

rbqlty

-

Weight (KG):

-

80

-

Motor Power (kw):

-

15 kw

-

Warranty of core components:

-

24 months

-

Name:

-

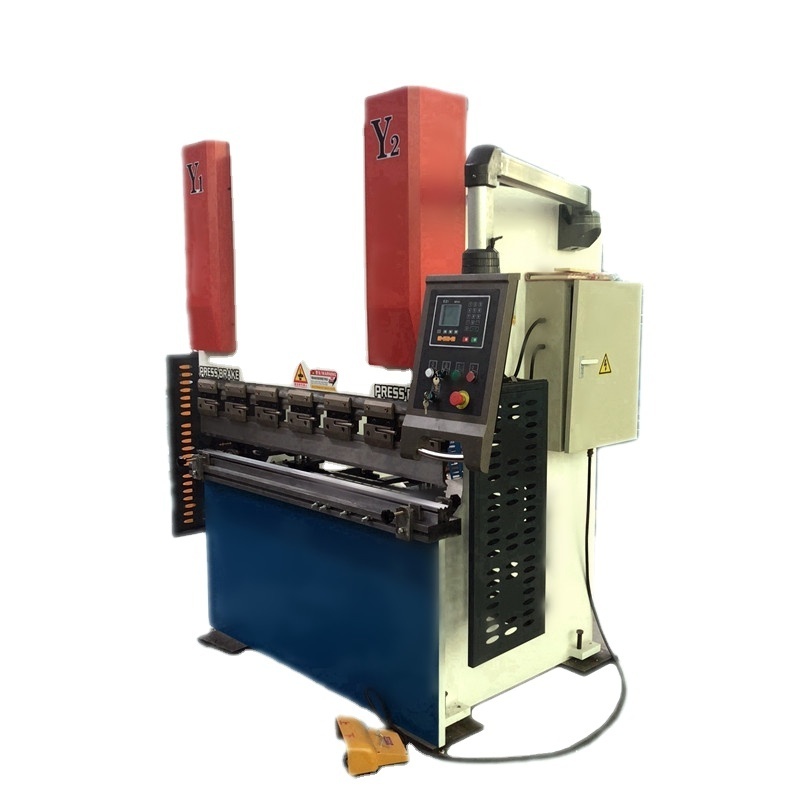

E21 small hydraulic nc press brake

-

Color:

-

Customized

-

Type:

-

Metal Bender Tools

-

Usage:

-

Metal Sheet Rolling Cutting Bending

-

Model:

-

WC67K-63T/1600

-

Material:

-

Stainess Steel

-

Size:

-

2600*1800*2540mm

-

Application:

-

stainless steel

Quick Details

-

Machine Type:

-

Torsion Bar

-

Length of Working Table (mm):

-

1600

-

Slider Stroke (mm):

-

1600 mm

-

Throat Depth (mm):

-

250 mm

-

Width of Working Table (mm):

-

1600 mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

rbqlty

-

Weight (KG):

-

80

-

Motor Power (kw):

-

15 kw

-

Warranty of core components:

-

24 months

-

Name:

-

E21 small hydraulic nc press brake

-

Color:

-

Customized

-

Type:

-

Metal Bender Tools

-

Usage:

-

Metal Sheet Rolling Cutting Bending

-

Model:

-

WC67K-63T/1600

-

Material:

-

Stainess Steel

-

Size:

-

2600*1800*2540mm

-

Application:

-

stainless steel

NC and CNC hydraulic sheet metal bending brake

A press brake is a machine tool for bending sheet and plate material, most commonly sheet metal. It forms predetermined bends by clamping the workpiece between a matching punch and die.

A brake can be described by basic parameters, such as the force or tonnage and the working length.Additional parameters include the stroke length, the distance between the frame uprights or side housings, back gauge distance, and work height.

Crowning Device

3 types: manual crowning, electric mechanical crowning and hydraulic crowning

Working principle:

The weight of long and heavy workpiece can cause the ram and worktable some deformation during the process of bending: the crowing device can improve the precision of press brake by making relevant different mechanism compensation to the ram deformation. it is especially applied to make some high precision products such as stainless steel.

High Precision Backgauge Device

Multi-Axes Solutions

Ram stroke: Y1, Y2 Backgauge: X, R, Z1, Z2 Compensation axis: V

China CNC systems:E21, E200, E300, MD11, MD320, MD330

Holland CNC systems: DA-52S, DA-56S, DA-66T, DA-69T

Torsion Bar Synchro NC Hydraulic Press Brake

1.Integrated steel plate welding structure;

2.double hydraulic cylinder transmission;

3.torsion bar synchro;

4.back gauge position X axis and ram stroke Y axis NC control; DA41 E300 CYBTOUCH8 bending angle control

5.multi-step programming memory

6. real-time bending amount display ;

7. power off memory of program technical data.

Electro-hydro Servo Synchro CNC Press Brake

1.integrated welding and vibratory stress relief;

2.electro-hydro servo valve and grating ruler for closed loop control;

2.high precision of backgauge position and re-positioning;

3.maximum 6 backgauge axis;

4.auto hydraulic crowning controlled by controller;

5.CNC system including DELEM (Netherlands), ESA (Italy), CYBELEC (Switzerland) etc.

|

Standard configuration

|

|

|

|

|

NC press brake

|

WC67K

|

CNC press brake

|

WE67K

|

|

Control system

|

Estun, Delem

|

Gear pump

|

America sunny

|

|

Crescent gear pump

|

America sunny

|

Seal ring

|

Japan NOK

|

|

Hydraulic system

|

Germany Rexroth

|

Control system

|

Delem, Cybelec,ESA

|

|

Oil tank seal ring

|

Japan NOK

|

Grating ruler

|

Germany HEIDENHAIN

|

|

Bite type fittings

|

Germany JS

|

Main motor

|

Sangta

|

|

Motor

|

Germany Siemens

|

Servo motor

|

Nanjin Estun

|

|

Electrical components

|

France Schneider

|

Main electronic components

|

France Schneider

|

|

Mould

|

Material (42CrMo)

|

Oil cylinder

|

Jining taifeng

|

|

Cylinder

|

Anhui Wuyang

|

square guide rail

|

Taiwan Hiwin

|

Back Gauge

Option: 1 axis to 6 axis back gauge according to your need

X / X+R / X+R+Z1+Z2 / X+R+Z1+Z2 / X+R+Z1+Z2+X Prime / X1+X2+R1+R2+Z1+Z2

6 axis

Press Brake Controller

For torsion bar synchro NC hydraulic press brake, we provide the E21 with steppor motor or E200, E300, DA41 and DA41s controller with servo system.

For electro-hydro servo synchro CNC press brake, we provide DA52s, DA58T, DA66T and CybTouch 8, CybTouch 12 controller.

Standard Press Brake Toolings

Free Standard lower 4 way die block, and segment upper punch

Generally, the press brake toolings are customized based on final products or workpieces.

Additional press brake toolings

By your tool design or your workpiece drawings, We provide you various press brake upper punch, lower die, hemming tools, offset tools, tool clampings etc.

Safety light curtain

Option:

infrared light or laser light

Option: manual crowning or motorized crowing or hydraulic crowning

Accessaries

foot pedal and lubrication oil pot and 2 front support arms

Motor

Option: steppor motor or servo motor

linear guide rail

Option: square guide or round guide

|

Payment Method

|

|

|

||

|

T/T

|

FOB

|

30% T/T in advance, the balance paid before shipping

|

||

|

|

CRF

|

30% T/T in advance, paid the balance against copy of B/L

|

||

|

|

CIF

|

|

||

|

L/C

|

L/C at sight or L/C 30 days is also accepted

|

|

||

|

D/P

|

D/P is available for long-term cooperated customer

|

|

||

|

Lead time

|

Normally 7-15 days after deposit or L/C received

|

|

||

Trade Assurance Payment

100% product quality protection

100% on-time shipment protection

100% payment amount protection

Packaging & Delivery

Shipping Fee is depend on package size and weight

Plastic Film or wooden box or customized package Full container load or less container load

Ru nbang Heavy Machine Co.,Ltd

We make sheet metal processing machine like bending machine, shearing machine, iron worker, hydraulic press, punching machine, duct manufacturing auto line, cutting machine and so on

Expert Team

With an expert team in R&D for more than 20 years, occupied the work shop of over 30,000 square meters, Runbang is able to support you with best quality machines .

Service Terms

1. Lifetime service, test before shipment

2. Online video and voice instruction

3. Online or Oversea Installation service

4. Online or Oversea Training service

5. 1 year warranty, free machine parts replacement

6. 100% response rate within 12 hours.