- Product Details

- {{item.text}}

Quick Details

-

Protection type:

-

IP54

-

Frequency:

-

50hz/60hz

-

Electromagnetic valve voltage:

-

24V DC

-

Output voltage (to the gun):

-

0-100KV adjustable

-

Powder consumption:

-

Max 600g/min

-

Input air pressure:

-

0-0.6Mpa

-

Output power voltage:

-

0 -100KV

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Maximum output current for the gun:

-

180UA

-

Polarity:

-

Negative

-

Protection type:

-

IP54

-

Frequency:

-

50hz/60hz

-

Electromagnetic valve voltage:

-

24V DC

-

Output voltage (to the gun):

-

0-100KV adjustable

-

Powder consumption:

-

Max 600g/min

-

Input air pressure:

-

0-0.6Mpa

-

Output power voltage:

-

0 -100KV

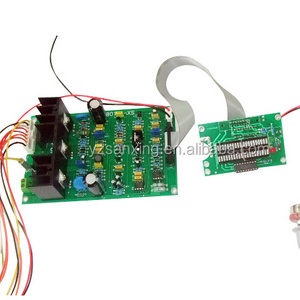

Manual powder coating spray gun from China leading manufacturer

The Manual powder gun is built exclusively for the electrostatic coating.

Quick and simple color change

Suitable for all kinds of flat or corner parts coating

Easy for LAB for small parts coating

Manual powder coating guns are suitable with various metal parts such as car rim, wheel, furnitures,electric box,transformer,refrigeritor,air conditions and so on. Polyester and epoxy powder are all available for gun coating.

We can also supply replacement spare parts-NON OEM part-compatible with Gema products

- B Manual powder gun body (incl. cascade), negative polarity 1006 099

- C Cascade (negative polarity) - complete 1000 809

- 1 Gun body 1001 155 Grip - complete set (pos. 5, 6, 7 and 8) 1000 807

- 2 Trigger - complete (incl. pos. 3) 1001 341

- 3 Compression spring - 0,36x4,2x49,4 mm 1001 487

- 4 Trigger cover 1000 801

- 5 Grip 1000 806

- 6 Radial gasket 1000 803

- 7 Gun cable - L=2 m, complete 1006 096 Extension cable for gun cable - L=14m, incl. clamp 1002 162 Cable clamp for extension cable 1002 064

- 8 Grub screw - M3x8 mm 1000 844

- 10 Powder tube - complete 1001 339

- 10.2 O-ring - Ø 12x1.5 mm 1000 822

- 11 Rinsing air connection 1000 804

- 12 Clip ring 1000 898

- 13 Compression spring 1001 488

- 14 Hopper cover - complete 1000 617

- 14.1 Print holder - complete (incl. pos. 14.2) 1002 029

- 14.2 Radial gasket 1000 795

- 14.3 Gun holder plate - complete 1002 028

- 14.4 Cap screw - M3x8 mm (not shown) 202 363

- 15 Diffuser - complete (see corresponding spare parts list)

- 16 Mounting hook (exchangeable) 1000 877

- 17 Countersunk head screw - M 4x8 mm, plastic 263 516

- 18 PT-screw 1000 843

- 19 Threaded sleeve - complete 1000 948

- 20 Flat jet nozzle - complete 1000 047

- 20.1 Electrode holder - complete 1000 055

- 20.2 Flat jet nozzle 1000 049

- Cleaning brush - Ø 12 mm 389 765

- Parts set (not shown), consisting of: 1002 359

- Round jet nozzle - NS02, complete 382 922

- Cable clamp 303 070

- Deflector - Ø 16 mm 331 341

- Deflector - Ø 24 mm 331 333

- Deflector - Ø 32 mm 331 325

- O-ring - Ø 12x1.5 mm 1000 822

- Countersunk head screw - M 4x8 mm, plastic 263 516

- Powder hose - Ø 7 mm (not shown) 1005 097

The process of the coating

The process of the coating is like this :the powder is fluidized in the powder hopper. The injectors transport the powder through the hoses to the guns . The guns spray a powder/air mixture onto the workpieces.

Powder coating

The powder coating process involves three basic steps:

- Part preparation or the pre-treatment

- The powder application

-

Curing

COLO Powder Coating Systems is a top supplier of powder coating systems and powder coating equipment including automated equipment, spray booths and spare parts famous brand in china.