- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Jonson

-

Dimension(L*W*H):

-

390mm*250mm*240mm

-

Weight:

-

12.35 KG

-

Working Temperature Range:

-

0 - 1000 ℃

-

Core Components:

-

IGBT, circuit board

-

rated power:

-

20KW

-

Power adjustment range:

-

20%~100%

-

Voltage adaptation range:

-

320V~440V

-

Rated voltage:

-

380V

-

Adapt to ambient temperature:

-

-20 degrees Celsius to 50 degrees Celsius

-

Main circuit structure:

-

Full bridge series resonance

-

Adapt to environmental humidity:

-

Less than or equal to 95%

-

Heat dissipation mode:

-

Air-cooled / water-cooled

-

monitor:

-

Programmable digital display

-

Application mode:

-

Open application platform

Quick Details

-

Type:

-

Induction Heater

-

Power Source:

-

Electric

-

Voltage:

-

380v

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Jonson

-

Dimension(L*W*H):

-

390mm*250mm*240mm

-

Weight:

-

12.35 KG

-

Working Temperature Range:

-

0 - 1000 ℃

-

Core Components:

-

IGBT, circuit board

-

rated power:

-

20KW

-

Power adjustment range:

-

20%~100%

-

Voltage adaptation range:

-

320V~440V

-

Rated voltage:

-

380V

-

Adapt to ambient temperature:

-

-20 degrees Celsius to 50 degrees Celsius

-

Main circuit structure:

-

Full bridge series resonance

-

Adapt to environmental humidity:

-

Less than or equal to 95%

-

Heat dissipation mode:

-

Air-cooled / water-cooled

-

monitor:

-

Programmable digital display

-

Application mode:

-

Open application platform

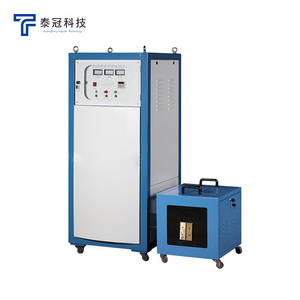

Product Overview

20KW electromagnetic heater

Electromagnetic induction heater is a technology to convert the AC voltage into a DC voltage 50-60HZ, and then through the controller converts the DC voltage into high-frequency voltage 13-18KHZ frequency, the current changes rapidly changing at high speed through the coil will produce a magnetic field when the magnetic field lines in the magnetic field by conducting numerous small eddy current is generated, the high-speed self-heating of the iron itself, so as to achieve the purpose of heating! of electromagnetic electric heater section uses advanced micro-processing chip technology, rugged design provides a safe and reliable guarantee for continuous working conditions. The microcomputer control technology to control the whole process of heating, the heater is achieved soft start and stop, automatically adjust the output power, automatic testing procedures, the self-test operation malfunction heating means, and a non-normal operating state diagnosis and protection functions. The heating temperature may be set in advance and displayed significant savings in production costs. Special design provides greater effect at lower consumption of energy saving.

Advantage

1. heating speed shorten the preheating time is 2/3 of the same conditions.

2. Actual energy-saving effect of up to more than 40 percent.

3. can work, output power, high efficiency.

4. heating process is safe, reliable, no fire, no pollution, environmental protection, no accidents.

5. the outer heating portion temperature reduction equipment can touch the hand, thus working environment has been significantly improved.

6. intelligent electromagnetic heater having automatic overcurrent and overvoltage protection, the IGBT over-temperature protection, fault alarm display will show the corresponding fault code, easy to find the cause quickly resolve.

7. temperature display and control the heating process.

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

1

|

Power

|

Three-phase 20KW

|

|

2

|

Rated input current

|

27-30(A)

|

|

3

|

Rated output current

|

30-50(A)

|

|

4

|

Rated voltage frequency

|

AC 380V/50Hz-60Hz

|

|

5

|

Voltage adaptation range

|

constant power output at 300 ~ 400V

|

|

6

|

Adapt to ambient temperature

|

-20ºC~50ºC

|

|

7

|

Adapt to environmental humidity

|

≤95%

|

|

8

|

Heat conversion efficiency

|

≥95%

|

|

9

|

Effective power

|

≥98%(Can be customized according to user needs)

|

|

10

|

working frequency

|

5~40KHz

|

FEATURES AT A GLANCE

energy saving

efficient

With 485 communication

Wide inductance design

digital programmable technology

DSP high-speed control

Easy to install and debug

Right elevation

Left elevation

Front elevation

Application range of electromagnetic heater:

1. Plastic and rubber industry, such as: plastic film blowing machine, wire drawing machine, injection molding machine, pelletizer, rubber extruder, vulcanizer, cable production extruder, etc.

2. Electromagnetic heating furnaces include: electromagnetic hot water furnaces, electromagnetic heating furnaces, electromagnetic steam boilers, and electromagnetic heat transfer oil furnaces.

3. The melting furnace industry has: electromagnetic heating copper melting furnace, aluminum melting furnace, zinc melting furnace, which can save electricity by about 50%.

4. Pharmaceutical and chemical industry, such as: medical infusion bags, plastic equipment production lines, liquid heating pipelines for chemical industry

5. Energy and food industries, such as: heating of crude oil pipelines; food machinery, such as over-cargo aircraft, and other equipment that requires electrical heating.

6. High-power commercial induction cooker movement.

7. Building materials industry, such as: gas pipe production line, plastic pipe production line, PE plastic rigid flat mesh, geonet unit, automatic hollow forming machine, PE honeycomb panel production line, single and double wall corrugated pipe extrusion production line, composite air cushion film unit, PVC rigid Pipe, core layer foamed pipe production line, PP extruded transparent sheet production line, extruded polystyrene foamed pipe, PE stretch film unit.

8. Dry heating in printing equipment.

Product Shipping

Exhibition

FAQ

1.How can I get the price?-We usually quote within 24 hours after we get your inquiry(Except weekend and holidays).

-If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

2. Can I buy samples placing orders?

-Yes.Please feel free to contact us.

3.What is your lead time?

-It depends on the order quantity and the season you place the order.

-Usually we can ship within 7-15 days for small quantity,and about 30 days for large quantity.

4.What is your payment term?

-T/T,Western Union,MoneyGram,and Paypal.This is negotiable.

5.What is the shipping method?

-It could be shipped by sea,by air or by express(EMS,UPS,DHL,TNT,FEDEX and ect).

Please confirm with us before placing orders.

6.How do you make our business long-term and good relationship?

-1. We keep goodquality and competitive price to ensure our customers benefit ;

-2. We respect every customer as our friend and we sincerely do business and make friends with them,no matter where they come from.

-If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

2. Can I buy samples placing orders?

-Yes.Please feel free to contact us.

3.What is your lead time?

-It depends on the order quantity and the season you place the order.

-Usually we can ship within 7-15 days for small quantity,and about 30 days for large quantity.

4.What is your payment term?

-T/T,Western Union,MoneyGram,and Paypal.This is negotiable.

5.What is the shipping method?

-It could be shipped by sea,by air or by express(EMS,UPS,DHL,TNT,FEDEX and ect).

Please confirm with us before placing orders.

6.How do you make our business long-term and good relationship?

-1. We keep goodquality and competitive price to ensure our customers benefit ;

-2. We respect every customer as our friend and we sincerely do business and make friends with them,no matter where they come from.

Hot Searches