- Product Details

- {{item.text}}

Quick Details

-

Machine Type:

-

soap making machine

-

Marketing Type:

-

New Product 2023

-

Capacity:

-

100/500/1000/2000/3000 KG/H

-

Raw Material:

-

soap noodle

Quick Details

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

taion

-

Weight (KG):

-

1500

-

Machine Type:

-

soap making machine

-

Marketing Type:

-

New Product 2023

-

Capacity:

-

100/500/1000/2000/3000 KG/H

-

Raw Material:

-

soap noodle

Product description

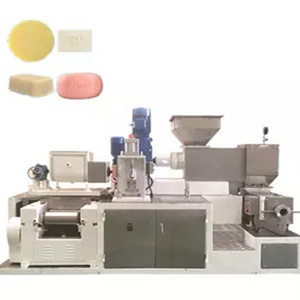

Made-In-China Liquid Soap Making Machine/bar Soap Making Machine/soap Press Machine Price

This set of production line is a soap molding production line with soap particles as raw materials and the output of 100-300 kg/h. After mixing raw materials, grinding, vacuum stripping, electronic roller printing and chopping, medium and high grade soap with fatty acid content of 35-70% can be produced. The production line adopts double-layer vacuum stripper, which can make the soap structure compact and not easy to dry and crack.

The process of small soap making machine starts with the mixing soap noodles. Then the mixed soap noodles enters in the three roll mill, where soap thin sheets are made. The sheet then converted into desired shape long strip soap by the plodding machine.Then the long strip soap are cut into the required size by cutting machine. Finally the soap bars gets packed by packing machine.

People-oriented design: Proctor Gamble management, mantel nuance and safety standards are adopted, the machines are more transparent ,better sealed, and have more safety measures.The maintenance workers can see machine parts running condition inside the machine at any time. The machine is tidy both outside and inside.

|

Capacity

|

|

300kg/h

|

|

|

|||

|

Power

|

|

5.5KW,7.5kw adjustable motor

|

|

|

|||

|

Dimension

|

|

2860*1100*2050mm

|

|

|

|||

|

Weight

|

|

1870kg

|

|

|

|||

Features of bar soap making machine:

1. This soap production line take soap noodles as raw materials.

2. It starts with mixing soap noodles and perfume.

3. Then the mixed soap noodles enters in the three roller mill by conveyor belt, where soap thin sheets are made.

4. The soap thin sheet then converted into desired long strip soap by the plodder machine.

5. Then the long strip soap are cut into the soap bars required size by cutting machine (there are two kinds of cutting machine. One is mechanical. The other is automatic).

6. Finally, the soap bars get packed by packing machine if needed.

7. Soap bars can be made 60g, 120g, 200g, 260g, and so on.

mixer

Two motors drive two stirring paddles to stir and mix soap particles with various liquid or powder additives. The two paddles rotate in opposite directions at different speeds, which is more conductive to fully breaking and mixing the soap materials.

three roller mill

The extrusion force between the three mixing rollers is strong, the grinding effect is good, and the production capacity will not be reduced when grinding special formula or relatively hard soap particles.

plodder machine

The primary sliver is equivalent to a single refiner, producing soap particles under vacuum. In the last stage, the soap grains are compressed, and after being extruded, they are continuously output in the form of soap bars through the nozzle for shaping by the downstream am cutting machine and printer.

cutting machine

For the toilet soap production line, the soap body from the plodder is cut into long strips by the cutting machine, and then input to the downstream printer.

For laundry soap, this cutting machine can install a complete set of rolling printing device at the front of the equipment, and realize the two functions of rolling printing and cutting at the same time, and directly produce finished soap for downstream packaging.

mold and finish product

Packing & Delivery

Our service

Our Company

Contact us

Hot Searches