- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2.2 * 2.2 * 2.22

-

Voltage:

-

Motor Customized

-

Power:

-

depends on machine

-

Weight (KG):

-

750

-

Raw material:

-

wood, coconut shells, bamboo

-

Usage:

-

making charcoal

-

Color:

-

Customer Required

-

Final product:

-

Charcoal Pieces

-

Feature:

-

Wood Charcoal Carbonization Stove Smokeless

-

Cooling Time:

-

8-9 Hours

-

Temperatur:

-

400-600 Degree

-

Advantage:

-

Continuous Working Environment Friendly

-

Fuel:

-

wood, gas

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

zhangsheng

-

Effective Volume:

-

8CBM

-

Dimension(L*W*H):

-

2.2 * 2.2 * 2.22

-

Voltage:

-

Motor Customized

-

Power:

-

depends on machine

-

Weight (KG):

-

750

-

Raw material:

-

wood, coconut shells, bamboo

-

Usage:

-

making charcoal

-

Color:

-

Customer Required

-

Final product:

-

Charcoal Pieces

-

Feature:

-

Wood Charcoal Carbonization Stove Smokeless

-

Cooling Time:

-

8-9 Hours

-

Temperatur:

-

400-600 Degree

-

Advantage:

-

Continuous Working Environment Friendly

-

Fuel:

-

wood, gas

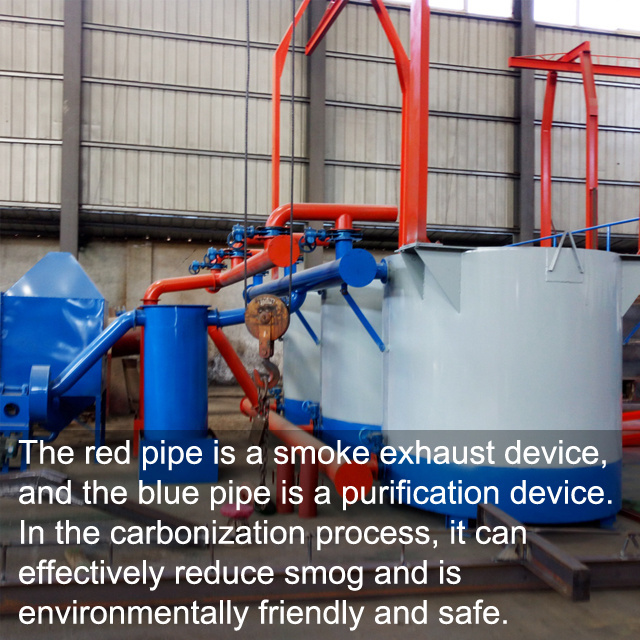

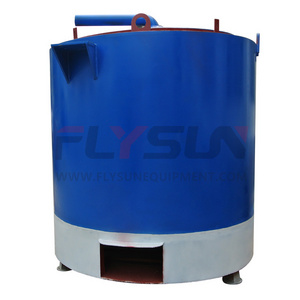

Hoisting Carbonization Furnace Product Description

H oisting Carbonization Furnace:

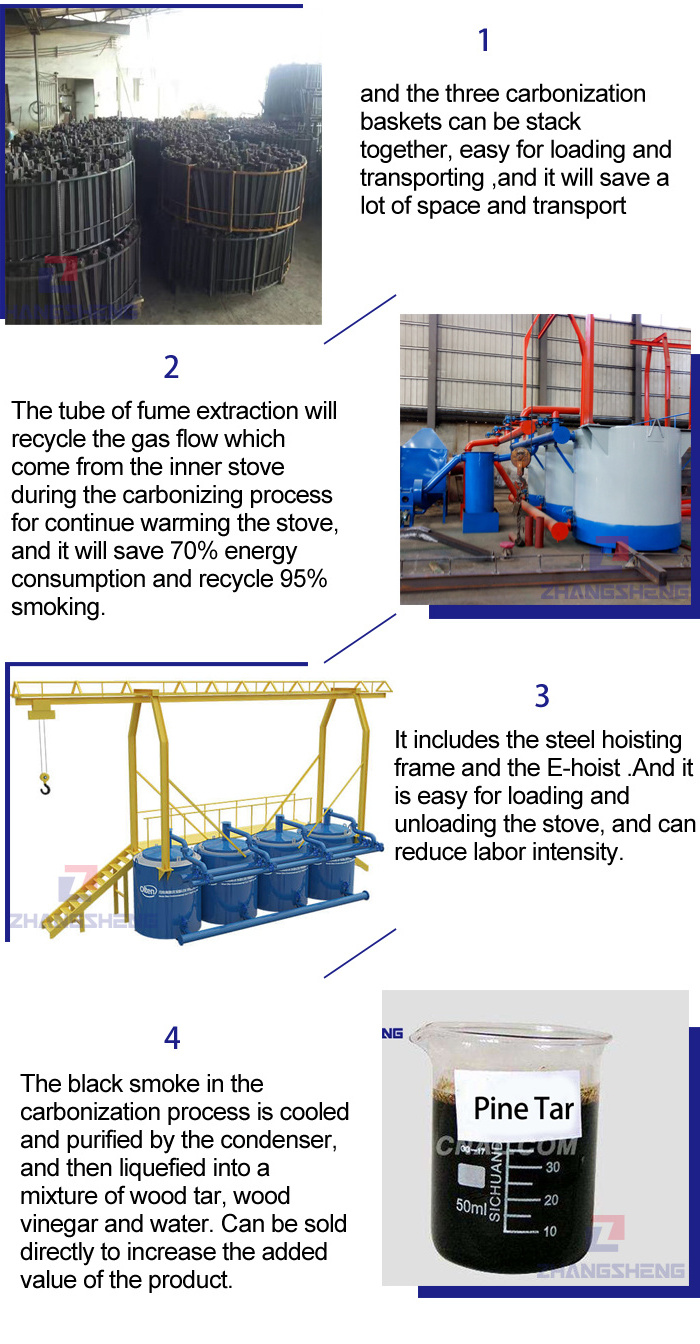

The whole machine adopts the hoisting combination structure, and each equipment is equipped with three internal furnace devices. After the first furnace carbonization, the second furnace carbonization can be directly carried out with a tank crane without preheating, improving the carbonization efficiency.

When the temperature of the continuous carbonization furnace exceeds 300℃, combustion g

as will be generated. After centralized recovery, they are separately introduced into the furnace bottom.Circulating heating and burning can effectively

reduce the use of fuel and reduce the cost .

Each furnace can process about one ton of logs or about two tons of semi-finished wooden sticks, Each batch raw materials will carbonize about 6 hours.And the carbonization rate is very high, when the furnace temperature is up to 700°C,the carbon rate will be up to 92%. and three furnaces can be used continuously without downtime.

|

Model

|

ZS-50

|

ZS-60

|

ZS-70

|

ZS-80

|

|

Capacity kg/h

|

120-180

|

200-240

|

280-350

|

320-380

|

|

Power/ kw

|

11

|

15/18.5

|

18.5

|

18.5

|

|

Diameter of the product /mm

|

50

|

60

|

70

|

80

|

|

Weight/kg

|

450

|

620

|

680

|

750

|

Raw materials and Finished product

Raw material can be Wood log, tree, tree branch, wood briquette, coconut shell, palm nutshell, Walnut Shell, Macadamia nutshell, bamboo, and other nut shell or hard raw material.

Product Advantages

Charcoal machine production line

If your raw material is Toner, there are several steps to make briquettes:

Our Service

We are a professional charcoal machine manufacturer in China. We have more than

20

years of experience in manufacturing charcoal machines. We can provide you with the following services:

1

. We will provide you with all wearing parts of the equipment for whole life, and give you the best factory price.

2

. After the ship leaves the loading port, when we receive the bill of lading, we will send you the proforma invoice, packing list, certificate of origin and other related documents together for your customs clearance.

3

. Before the equipment is shipped, we will test the machine. After loading the machine into the container, we can send the loading picture to you.

4

. We have long-term cooperation with many famous freight forwarder companies. We also provide CE, ISO9001, CO, Form E, COC, CIQ and other certifications to help customers from different countries to clear customs.

5

. We send engineers to your working site to help you install and debug equipment, build factories and train operators, At the same time, the charcoal production technology will be passed on to customers.

Hot Searches