- Product Details

- {{item.text}}

Quick Details

-

Printing Width:

-

600mm to 1600mm

-

Printing Length:

-

200mm to 1200mm

-

Register precision:

-

±0.25mm

-

Printing plate lifting system:

-

pneumatic control optional

-

Double unwinding optional:

-

double rewinding optional

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

2 colors flexo printing:

-

roll materials as PVC,OPP,BOPP,PE film,NY, PET film,CPP, Paper

-

Max. Printing speed:

-

60m/min

-

Printing Width:

-

600mm to 1600mm

-

Printing Length:

-

200mm to 1200mm

-

Register precision:

-

±0.25mm

-

Printing plate lifting system:

-

pneumatic control optional

-

Double unwinding optional:

-

double rewinding optional

(1) Efficient and satisfied service

(2) Complete machines solution for the whole production line

(3) Various and multi solutions for different requirement

(4) More than 18-year professional experience

(5) Qualified product and strict quality control

(6) ODM,OEM is welcome

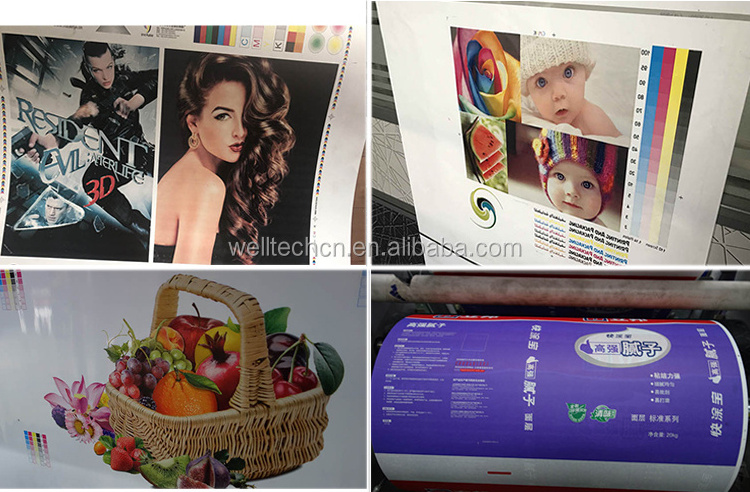

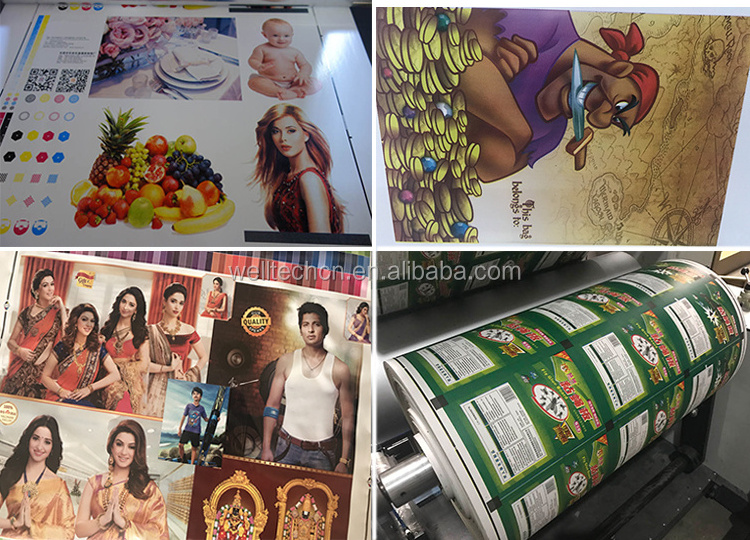

2 colors to 8 colors Flexographic Printing Machines Flexo Printers, 1 color to more than 10 colors Rotogravure Printing Machines such multi-colors multi-functional printing machines can be supplied. Max. printing speed can be 50m/min to 200m/min.

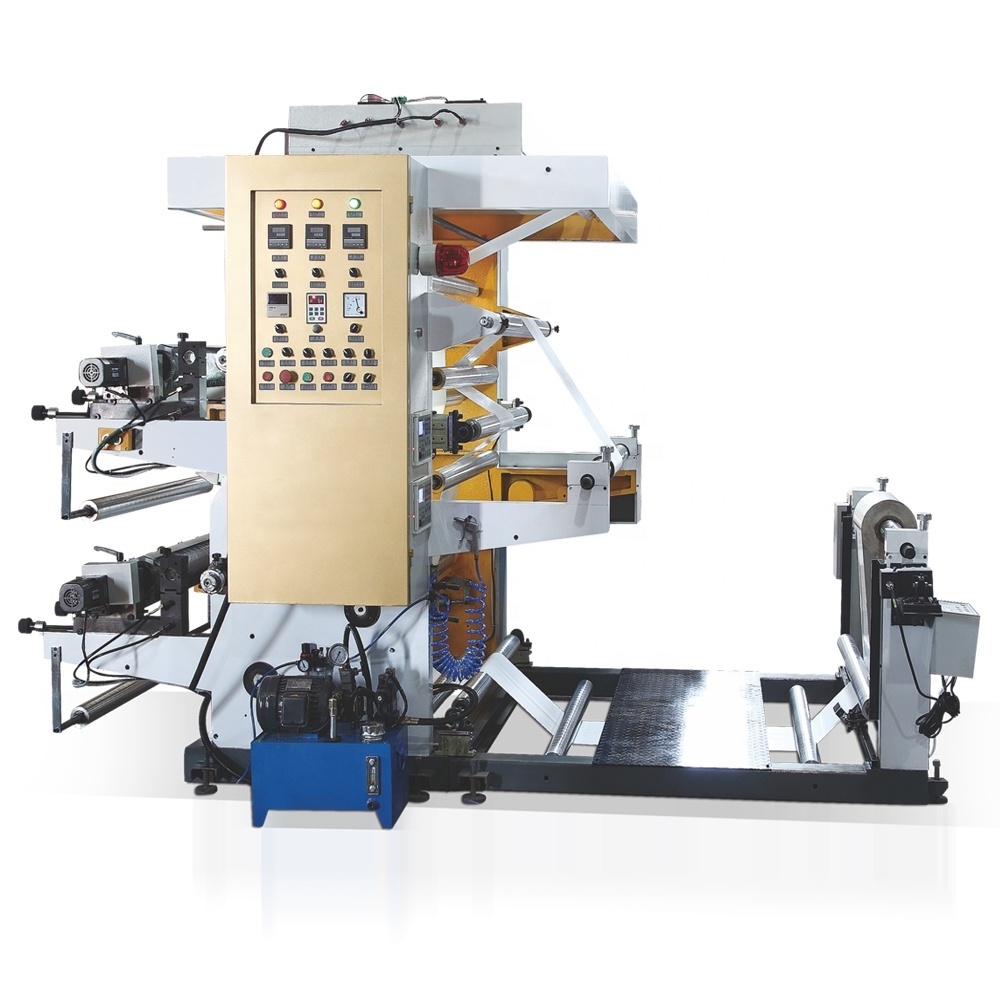

Description:

This machine is suitable for printing such packing materials as polyethylene, polyethylene plastic bag glass paper and roll

paper, etc. And it is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag

and clothes bag, etc.

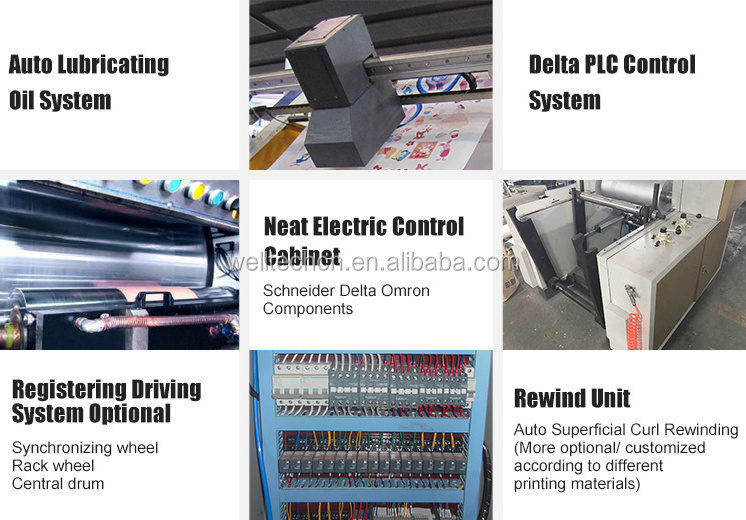

1. Easy operation, flexible starting accurate colour register.

2. The meter counter can set printing quantity according to the requirement. Stop the machine automatically at the set quantity

or when the material is cut off.

3. Lift and lower the printing plate cylinder manually, It will automatically stir the printing ink after lifting

4.The printing ink is spread by the knurled cylinder with even ink colour.

5. Reliable drying system coordinated with high-speed rotation, it will automatically break circuit when the machine stops.

6.360°continuous and adjustable longitudinal register device.

7. The imported frequency control of motor speed adapts to different printing speeds.

8. There are inching/Stopping buttons on the plate roller base and material rolling rack so as to make it easy operate the

machine when the plate is installed.

Optional Equipment:

Automatic material tension control system (for feeding and winding)

Auto skew correction device/adjuster

Air shaft: 4 pcs

Printing plate lifting system with Hydraulic pressure control

|

Model No.

|

WT-A2600

|

WT-A2800

|

WT-A21000

|

WT-A21200

|

|

Max. Web Width

|

600mm

|

800mm

|

1000mm

|

1200mm

|

|

Max. Effective Printing Width

|

560mm

|

760mm

|

960mm

|

1160mm

|

|

Range of Repeat Printing Length

|

190~960mm

|

190~960mm

|

190~960mm

|

190~960mm

|

|

Max. Diameter of Roll Material

|

450mm

|

450mm

|

450mm

|

450mm

|

|

Max. Mechanical Speed

|

70m/min

|

70m/min

|

70m/min

|

70m/min

|

|

Max. Printing Speed

|

60m/mmin

|

60m/mmin

|

60m/mmin

|

60m/mmin

|

|

Accuracy of Registration

|

±0.25mm

|

±0.25mm

|

±0.25mm

|

±0.25mm

|

|

Plate Thickness

|

2.38mm

|

2.38mm

|

2.38mm

|

2.38mm

|

|

Total Power

|

8.5kw

|

11.2kw

|

13.35kw

|

15.45kw

|

|

Weight

|

1800kg

|

2000kg

|

2200kg

|

2500kg

|

|

Overall Dimension(m)

|

2.5*1.7*2.2

|

2.5*1.9*2.2

|

2.5*2.1*2.2

|

2.5*2.3*2.2

|

The Complete Plastic Polythene Bags Production Line Machines including Film Blowing Machine, Printing Machine, Plastic Bag Making Machine, and Plastic Recycling Machines can be supplied. Multi solutions for the project of plastic bags production!