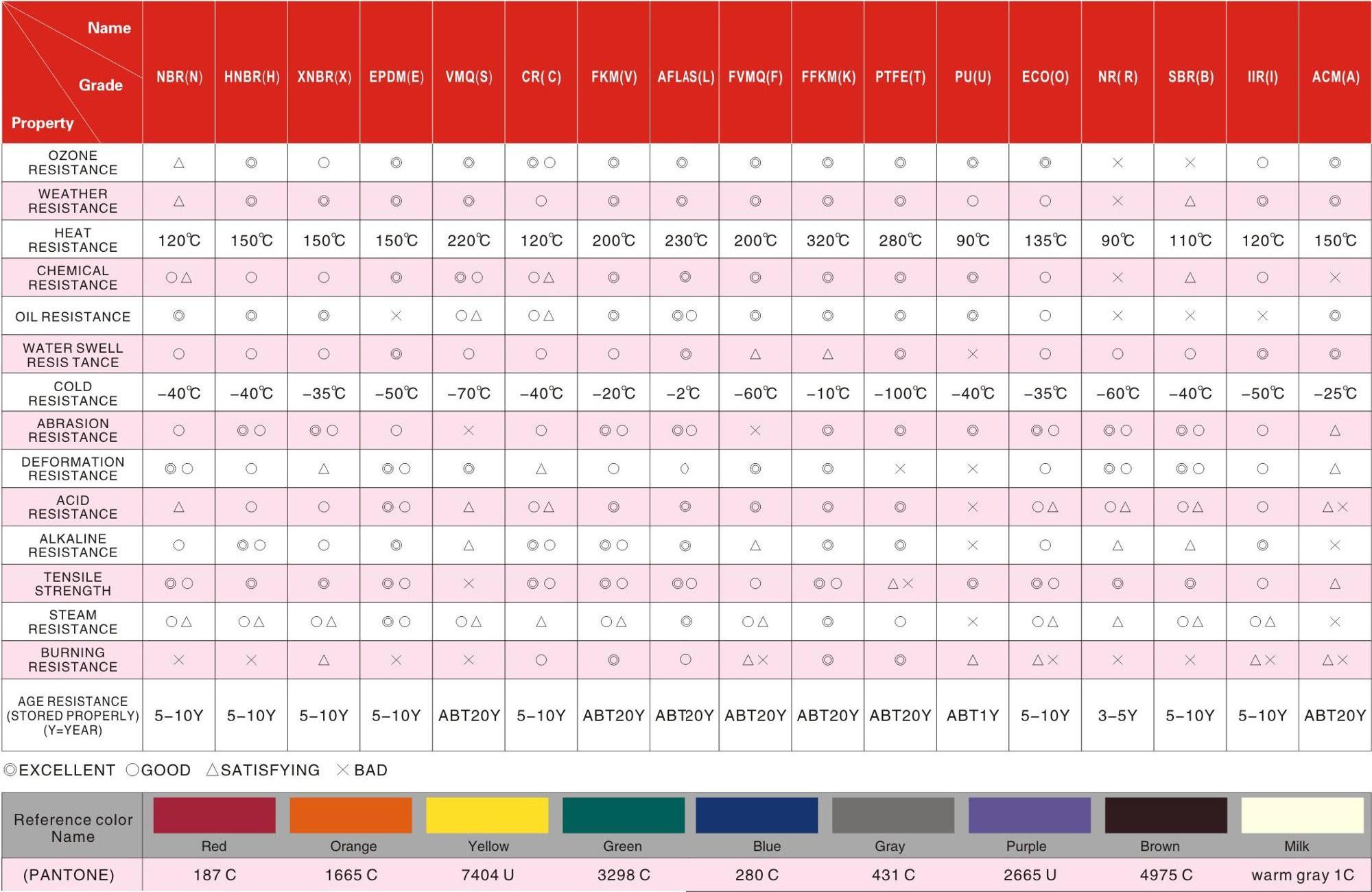

·NBR(Nitrile-Butadiene Rubber)·HNBR(Hydrogenated Acrylonitrile-butadiene Rubber)

·XNBR(Carboxylated nitrile rubber)

·EPDM/EPR(Ethylene-propylene)

·VMQ(Silicone rubber)

·CR(Neoprene Rubber)

·FKM/FPM(Fluorocarbon)

·AFLAS(Tetrapropyl Fluoro Elastomer)

·FVMQ(Fluorosilicone)

·FFKM(Aflas® or Kalrez®)

·PTFE(Poly tetra fluoroethylene)

·PU(Polyurethane)

·NR(Natural Rubber)

·SBR(Styrene-butadiene Rubber)

·IIR(Butyl Rubber)

·ACM(Acrylate Rubber)

If you need a special compound for the O-RING , we can develop one for you!

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Standard/Non-standard

-

Color:

-

Custom

-

Application:

-

All Industry

-

Certificate:

-

IATF16949/RoHS/REACH/PAHS/KTW/NSF

-

Material Type:

-

NBR FKM EPDM CR SIL PTFE etc.

-

Feature:

-

Sealing Performance/Wear Resistance/High&Low Temperature Resistance

-

MOQ:

-

20000pcs

-

Hardness:

-

According to the material

-

Packing:

-

Plastic Bag/Custom

-

Working temperature:

-

Choose Suitable Material

Quick Details

-

Size:

-

customized, Non-Standard/Standard

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Yokey/OEM

-

Model Number:

-

Standard/Non-standard

-

Color:

-

Custom

-

Application:

-

All Industry

-

Certificate:

-

IATF16949/RoHS/REACH/PAHS/KTW/NSF

-

Material Type:

-

NBR FKM EPDM CR SIL PTFE etc.

-

Feature:

-

Sealing Performance/Wear Resistance/High&Low Temperature Resistance

-

MOQ:

-

20000pcs

-

Hardness:

-

According to the material

-

Packing:

-

Plastic Bag/Custom

-

Working temperature:

-

Choose Suitable Material

Product Details

|

Product Info

|

|

|

|

Product name

|

O-RING

|

|

|

Material Type

|

NBR,EPDM,SIL,FKM,SBR,NR,etc.

|

|

|

Hardness Range

|

20-90 Shore A

|

|

|

Color

|

Customized

|

|

|

Size

|

AS568, PG & Non-Standard O-Rings

|

|

|

Application

|

Industries

|

|

|

Certificates

|

FDA,RoHS,REACH,PAHs

|

|

|

OEM / ODM

|

Available

|

|

|

Packing Details

|

PE plastic bags then to the carton / as per your request

|

|

|

Lead Time

|

1).1days if goods in stock

2).10days if we have existing mould

3).15days if need open new mould 4).10days if annual requirement informed |

|

|

Port of Loading

|

Ningbo

|

|

|

Shipping Method

|

SEA,AIR,DHL,UPS,FEDEX,TNT, etc.

|

|

|

Payment Terms

|

T/T,L/C,Paypal, Western Union

|

|

O-RING are available in the following elastomers:

At present, Yokey have more than 5000 specifications of o-ring mold ,can almost meet your any needs.

Send inquiries now to get more information!

PTFE COATING O-RING,

In the case of rubber elasticity and sealing, and has excellent corrosion resistance.

Company Introduction

NINGBO YOKEY PRECISION TECHNOLOGY CO.,LTD. is located in Ningbo, Zhejiang province, a port city of the Yangtze River Delta. The company is a modernized enterprise specializing in researching & developing, manufacturing, and marketing of rubber seals.

The company is armed with an experienced manufacturing team of international senior engineers and technicians, possessing mold processing centers of high precision and advanced imported test devices for products. We also adopt world-leading seal manufacturing technique in the whole course and choose raw material of high quality from Germany, America and Japan. Products are inspected and tested strictly for more than three times before delivery.

Our main products include O-ring, PTFE back-up ring, rubber washer, ED-ring, oil seal, rubber non-standard product and a series of dustproof polyurethane seals,which are widely used in high-ended manufacturing fields such as hydraulics, pneumatics,

mechatronics, chemical industry, medical treatment, water, aviation and auto parts.With excellent technology, steady quality, favorable price, punctual delivery and qualified service, seals in our company gain acceptance and trust from many renowned domestic customers, and win an international market, reaching out to America, Japan, Germany, Russia, India, Brazil and many other countries.

Our Services & Strength

1.We posses a development ,research,manufacturing and sales team.R&D team from Taiwan with over 20 years experience, 200 employees, two plants cover 13,000 square meters and produce 80 sets of equipment,which can provide our customers professional sealing solutions.

2.We have high-precision mold processing center introduced from Germany.The size tolerance of our products can be controlled in 0.01mm.

3.Our Raw materials imported from Germany and the United States The elongation and elastic resilience are better than industrial standard.Production equipment, die equipment and testing equipment imported from Germany, Japan and Taiwan.

4.We strictly conduct ISO 9001 IATF16949 quality control system.The products go through all inspection before delivery,and the pass percent can reach 99.9%.

5.We introduce the international processing technique of advanced level and constantly improve the automation level to save customer’s purchase cost of high-end sealing products.

Workshop

CNC Molding Center-which

can meet any of your custom needs.

Product Line-

Two shifts per day, 8 hours per shift,m

eet any of your production requirements.

Quality Inspection Center

Fully automatic optical tester-Make our products more reliable,pass percent can reach 99.99%.

Vulcanization

Equipment

Warehouse-

Stock of standard parts

Production Process

1.Rubber raw material mixing

2.Cut the rubber into clunks,strip out banding rubber

3.Vulcanization process

4.Product selection

5.Two times vulcanization process

6.Inspection and delivery

Testing Equipments

Vulcanization Tester

Tensile Strength Tester

Hardness Tester

High&low Temperature Test Chamber

Micro Measurement Tool

Projector

Customer Case&Certificate

RoHS2.0

PaHS

REACH

IATF16949

Professional production management system to make our products more quality

Exhibition

FAQ

1.Q:Where do you source your raw materials and how do you guarantee their quality?

A:NBR Imported from bayer, Germany.FKM imported from dupont USA,EPDM Imported from lanxess, USA,SIL Imported from the United States dow corning,all the raw materials are imported.

2.Q: What's the payment term?

A:We accept T/T 30% deposit and 70% balance against copy of L/C at sight, West Union,VISA,Paypal is also accepted.

3.Q: What is the normal lead time for product orders?

A:Average lead times for prototype / first article are 1-2 weeks, if tooling is involved, lead time for production tooling is 10 days, average production time after sample approval is 2-3 weeks.

4.Q:What is your standard packing?

A: All the goods will be packed by carton box and loaded with pallets. Special packing method can be accepted when needed.

5.Q:what kind of certificates you have ?

A:We have been ISO09001:2008 and IATF16949/PAHS/REACH/KTW/NSF.

6.Q:How to select the raw compound for my application?

A:With years of experience working with a variety of material, we can help select the material that will best suit your needs while keeping material costs in mind.

7.Q:What materials are available to produce from your side

A:NBR, EPDM, SILICONE, FKM, NEOPRENE(CR), NR, IIR, SBR, ACM, AEM, Fluorosilicone(FVMQ), FFKM etc.

8.Q: What is the life expectancy of the rubber seal?

A:Product life is contingent upon many factors, including environment, cycles, pressure, etc. Maihua Rubber cannot predict seal life under all the varying conditions of operation. Accellerated life testing may be performed by customer to determine expected life, but must be conducted in dynamic application.

9.Q:Does Yokey Precision Technology provide maintenance on tooling?

A:Yokey Precision Technology maintains all tooling and will replace as needed.

10.Q:How many empolyees you have?

A:We have 200 empolyees at time of December 2019.

11.Q:How many shifts per day in the factory?

A: Two shifts per day, 8 hours per shift.

Hot Searches