- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

770 KG

-

PTO Speed:

-

540r/min

-

Power Required:

-

80-120HP

-

Working width:

-

1600-2200 mm

-

ODM/OEM:

-

Provided

-

Linkage:

-

Rear Mounted Three-point Linkage

-

Drive type:

-

Tractor Hydraulic

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Online support

-

Certification:

-

CE,9001

Quick Details

-

Use:

-

mulching grass and prunnings among the rows

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

AWON

-

Weight:

-

770 KG

-

PTO Speed:

-

540r/min

-

Power Required:

-

80-120HP

-

Working width:

-

1600-2200 mm

-

ODM/OEM:

-

Provided

-

Linkage:

-

Rear Mounted Three-point Linkage

-

Drive type:

-

Tractor Hydraulic

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Online support

-

Certification:

-

CE,9001

Products Description

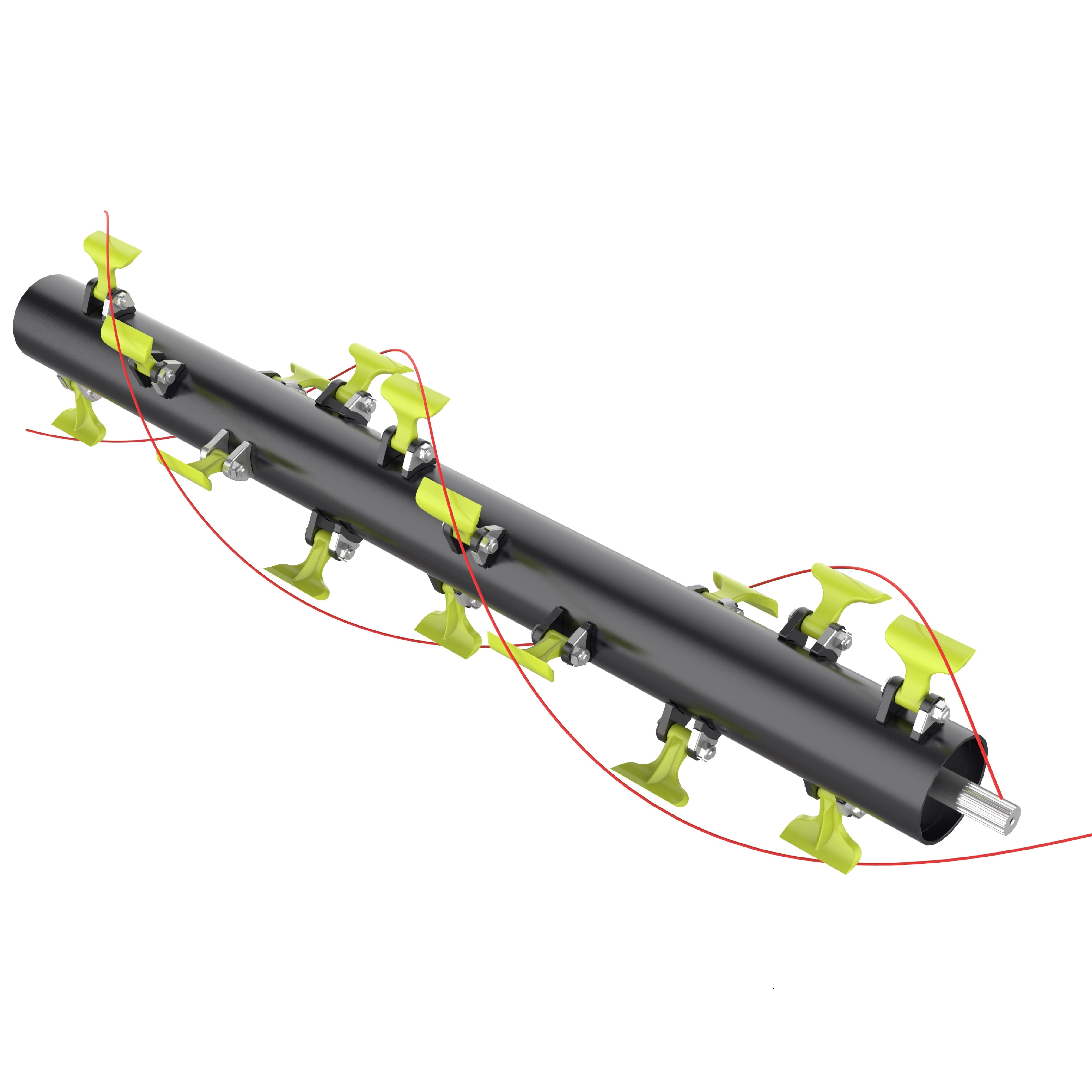

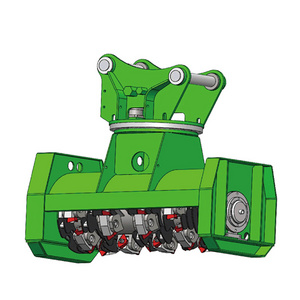

FTC offset series are rear mounted,PTO driven flail mowers for tractors. 4 models in total,working width varies from 1,600 to 2,200mm,power demand 70-100HP.FTC series are mowers for grass , pruning residues, vine shoots and branches of up to 2 cm of diameter. the side-shift by the tractor’s hydraulics could allow for shifting from one side to another.

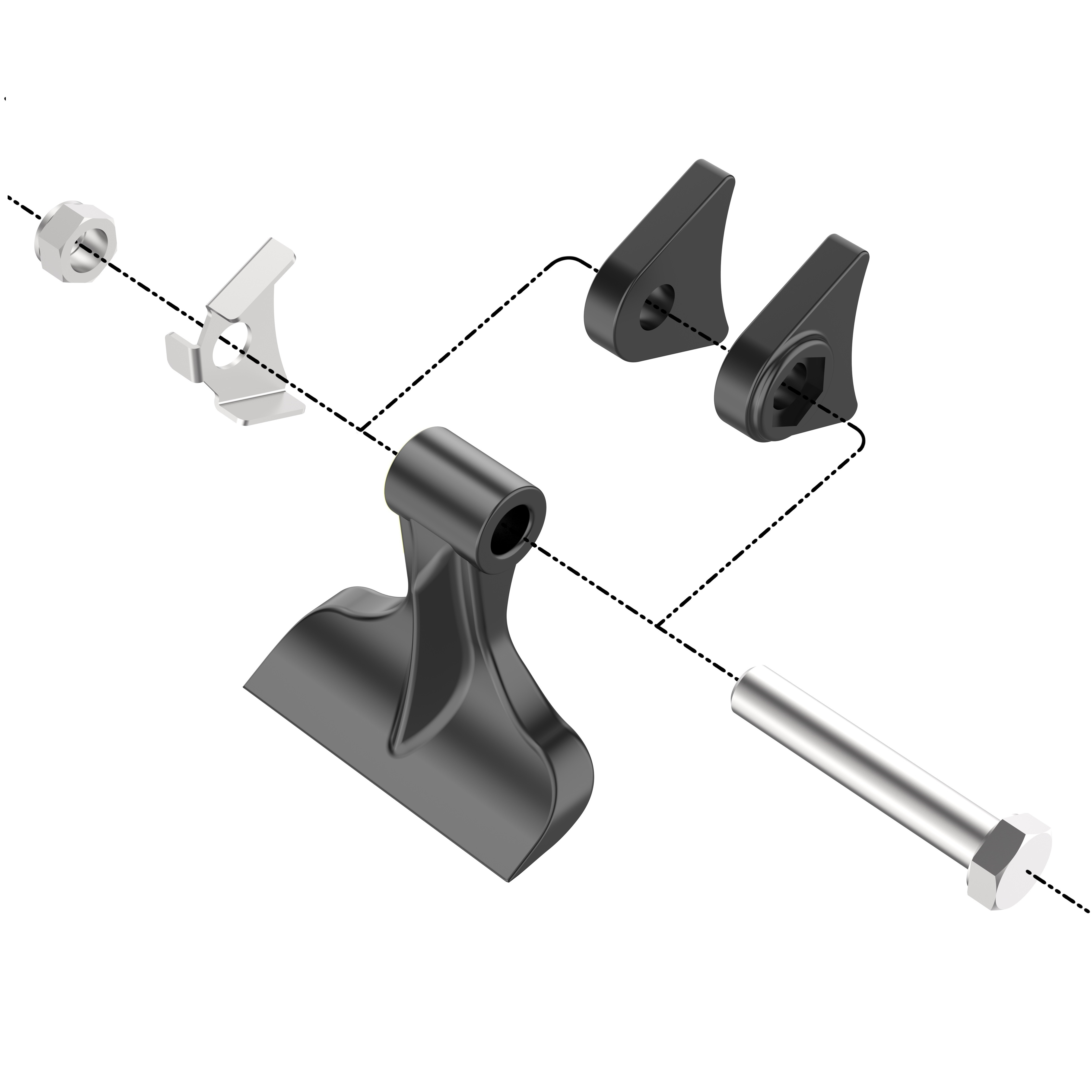

Standard Equipment

Shaft with double flail spiral• Overrunning clutch integrated with gearbox• Mechanical safety breakaway device • Mowing height adjustment with ground following bar • Wide-angle PTO shaft • Automatic tension of V-belts •Heavy-duty forged hammer blade•3-point hitch

Product Parameters

|

Model

|

FTC160

|

FTC180

|

FTC200

|

FTC220

|

|

Dimension(mm)

|

1810*1058*993

|

2010*1058*993

|

2210*1058*993

|

2410*1058*993

|

|

Weight(Kg)

|

630

|

680

|

720

|

770

|

|

Cutting Width(mm)

|

1600

|

1800

|

2000

|

2200

|

|

PTO Input Speed

|

540

|

540

|

540

|

540

|

|

Number of blades

|

16

|

18

|

20

|

22

|

|

Power required(HP)

|

70-100

|

70-100

|

70-100

|

70-100

|

Product Advantages

Advantages

* Mounting on 3-point hitch at the rear of the tractor linkage Cat.Ⅱ

* Mulch both behind and alongside the tractor

* Heavy-duty forged hammer blade provides extreme durability even with the thick branches

* Lightweight, compact design and at the same time high efficiency ensure economical use

* The belt drive ensures quiet operation of the machine.

* The wide range of working widths allows the machine to be adapted to the working conditions and the type of terrain

* Balanced weight and precise helical arrangement of flail knives provide effective operation in difficult conditions

* Perfect ground following and even cutting height

* Metal plate guards at the front and at the back provide effective protection against stones

* PTO shaft as standard

* Housing can be hydraulic lifted to leave the shredded materials back to the field

* Heavy-duty forged hammer blade provides extreme durability even with the thick branches

* Lightweight, compact design and at the same time high efficiency ensure economical use

* The belt drive ensures quiet operation of the machine.

* The wide range of working widths allows the machine to be adapted to the working conditions and the type of terrain

* Balanced weight and precise helical arrangement of flail knives provide effective operation in difficult conditions

* Perfect ground following and even cutting height

* Metal plate guards at the front and at the back provide effective protection against stones

* PTO shaft as standard

* Housing can be hydraulic lifted to leave the shredded materials back to the field

Hot Searches