- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1600*1000*2400 mm

-

Weight:

-

1-25ton

-

Rated Evaporation:

-

200kg/h

-

Working Pressure:

-

0.4/0.7Mpa

-

Feed Water Temperature:

-

20℃

-

Water Volume:

-

29L

-

Steam Temperature:

-

171 ℃

-

Thermal efficiency:

-

95%

-

Model:

-

LSG

-

Control system:

-

Automatic Control System

-

Keywords:

-

Biomass steam generator

Quick Details

-

Core Components:

-

Boiler Furnace

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XINDA

-

Dimension(L*W*H):

-

1600*1000*2400 mm

-

Weight:

-

1-25ton

-

Rated Evaporation:

-

200kg/h

-

Working Pressure:

-

0.4/0.7Mpa

-

Feed Water Temperature:

-

20℃

-

Water Volume:

-

29L

-

Steam Temperature:

-

171 ℃

-

Thermal efficiency:

-

95%

-

Model:

-

LSG

-

Control system:

-

Automatic Control System

-

Keywords:

-

Biomass steam generator

Product Description

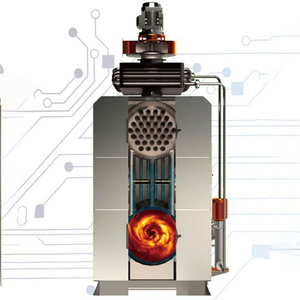

Vertical 100 to 2000kg Steam Boiler Manual Biomass Wood Fired Industry Vertical Steam Generator For Dry Cleaning Machine Price

Introduction to Biomass Steam Boiler:

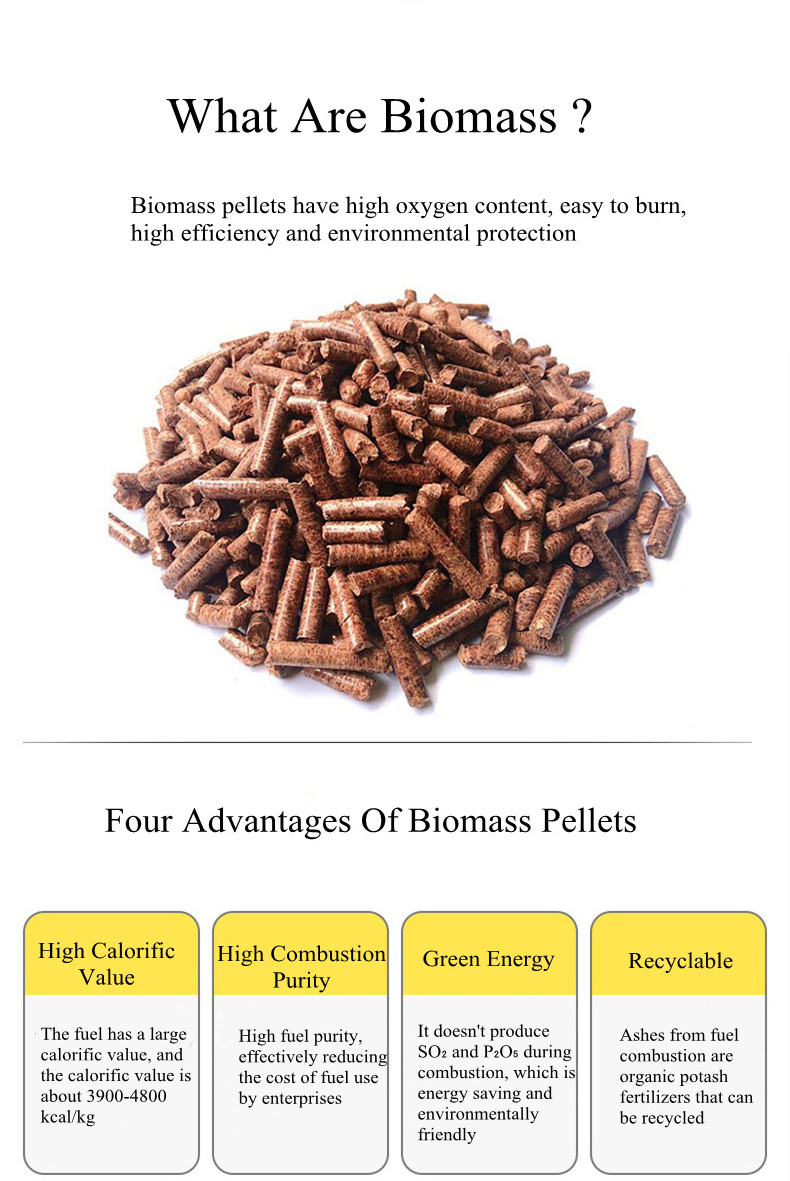

Xinda vertical biomass steam generator, using low-cost biomass pellets as fuel, is an automatic inspection-free steam generator. Energy saving and environmental protection. Using the most advanced semi-gasification compound combustion technology, microcomputer control system and modular design, it has the advantages of fully automatic intelligent operation, unsupervised, inspection-free, simple operation and maintenance, fast steam production, and high steam dryness. The best choice to replace coal, oil, gas, and electric heating boilers, saving 30-80% of operating costs.

|

Type

|

LSG0.05

|

LSG0.1

|

LSG0.2

|

LSG0.3

|

LSG0.5

|

||||

|

Rated Evaporation(kg)

|

50

|

100

|

200

|

300

|

500

|

||||

|

Rated Steam Pressure(MPa)

|

0.4

|

0.4

|

0.4

|

0.7

|

0.7

|

||||

|

Power Supply

|

220v/50hz

|

|

|

|

|

||||

|

Steam temp

|

150℃

|

150℃

|

150℃

|

170℃

|

170℃

|

||||

|

Main Body Dimension(mm)

|

1500*800*1600

|

1500*900*1800

|

1600*1000*2000

|

1800*1300*2000

|

2200*1500*2200

|

||||

|

Weigh(kg)

|

670

|

900

|

1200

|

1460

|

2600

|

||||

Biomass Steam Boilers features:

1. The boiler heats up quickly and has high thermal efficiency. The boiler operates with high thermal efficiency.

2. Beautiful appearance, using heat-resistant insulation materials and high-grade color board outer packaging.

3. The operation is simple, it can run for several hours after adding coal at a time, and users can enjoy all-weather heating.

4. Energy saving and economical, using adiabatic combustion, high combustion efficiency, low fuel costs.

5. The original exhaust dust concentration is low, environmental protection and energy saving. It reduces fuel consumption and protects the environment.

6. Small size, low investment cost of biomass steam boiler, and saving more than 50% in boiler room investment compared with other furnace types.

7. Environmental protection meets the standards, adopts the design of up-combustion mechanism to meet the smoke and dust emission standards of coal-fired boilers.

1. The boiler heats up quickly and has high thermal efficiency. The boiler operates with high thermal efficiency.

2. Beautiful appearance, using heat-resistant insulation materials and high-grade color board outer packaging.

3. The operation is simple, it can run for several hours after adding coal at a time, and users can enjoy all-weather heating.

4. Energy saving and economical, using adiabatic combustion, high combustion efficiency, low fuel costs.

5. The original exhaust dust concentration is low, environmental protection and energy saving. It reduces fuel consumption and protects the environment.

6. Small size, low investment cost of biomass steam boiler, and saving more than 50% in boiler room investment compared with other furnace types.

7. Environmental protection meets the standards, adopts the design of up-combustion mechanism to meet the smoke and dust emission standards of coal-fired boilers.

Boiler advantage

Application

Packing & Delivery

Our Company

Certifications

Exhibition

Our Services

Hot Searches