- Product Details

- {{item.text}}

Quick Details

-

Power:

-

11kw

-

Weight:

-

950

-

Dimension(L*W*H):

-

1606x1000x605 mm

-

Description:

-

China waste oil centrifuge separator for sale

-

Material(drum):

-

SS304

-

Capacity:

-

0.5-1T/h

-

Drum length:

-

930mm

-

Drum inner diameter:

-

220mm

-

Drum rotation speed:

-

0-5000r/min( stepless adjustable)

-

Setting speed:

-

4600r/min

-

Max.separation factor:

-

2725w2/g

-

Differential speed:

-

13.16.19( stepless adjustable)

-

Overflow diameter(mm):

-

80.5

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Toper

-

Voltage:

-

380V/400-450V

-

Power:

-

11kw

-

Weight:

-

950

-

Dimension(L*W*H):

-

1606x1000x605 mm

-

Description:

-

China waste oil centrifuge separator for sale

-

Material(drum):

-

SS304

-

Capacity:

-

0.5-1T/h

-

Drum length:

-

930mm

-

Drum inner diameter:

-

220mm

-

Drum rotation speed:

-

0-5000r/min( stepless adjustable)

-

Setting speed:

-

4600r/min

-

Max.separation factor:

-

2725w2/g

-

Differential speed:

-

13.16.19( stepless adjustable)

-

Overflow diameter(mm):

-

80.5

China waste oil centrifuge separator for sale

Product Description

Brief introduction of China waste oil centrifuge separator for sale

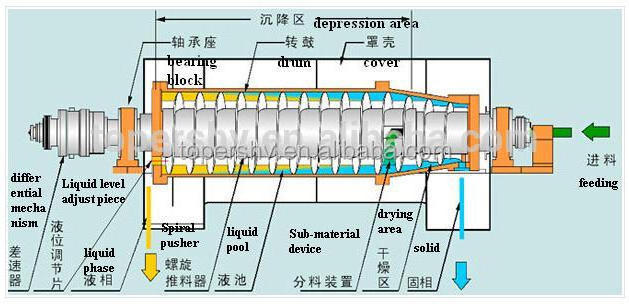

Decanter centrifuge uses the centrifugal sedimentation to separate the suspension, uses the spiral to unloading material. It is continuously charging, separating, discharging at full speed.

It is used in the suspension(in 0.0005~ 2mm, concentration 2-40%) solid-and-liquid separation, size classification, liquid clarification .

Especially , i t is suitable for the suspension separation that with difficult in filter cloth recycling, and the material with large concentration and big size range.

Working principle of China waste oil centrifuge separator for sale

There is spiral which is the feeding spiral which is has the same axis with the drum.The spiral and the drum rotate in different speed but in the same direction.The rotate difference is caused by the differential. The suspension enters the spiral through the feeding pump in the centre, when it starts to speed up the material goes into the drum.

Under the effect of the centrifuge force, the relatively heavy solidoid sediments into slag blanket on the surface of the drum wall, then the spiral push the slag blanket to the drum cone section for further dehydration, latter it will be discharged from the small section slag hole.While the relatively light liquicdoid forms the inner liquid cycle, and it will be discharged from the large end overflow gate.

Basic structure of China waste oil centrifuge separator for sale

Main features on design and structure:

(1) The overall design of the machine using the advanced models on the international market: the motor set at side, cover on the base flatted, this type of structure make the machine more convenient maintenance, low noise, vibration small, easy to install .

(2) Stainless steel outer cover, using a closed design, odor is not out when on the woking process, make the workplace more environmentally .

(3)Drum made of 304 stainless steel.

(4) The use of square steel pipe base, rather than the assembly welding, to make the appearance more beautiful, less internal frame welding stresses.

(5) The machine damping device using high modulus of elasticity drum vibration absorbing damping device, the vibration of the machine is smaller, greatly reducing the impact on the basis of vibration compared to previo

The main pieces of material and brand equipment standard instructions :

- The main standard parts are:

01. main and auxiliary bearings 02. inner seal 03. internal fastening screws

(1)Seiko Japan NSK Bearings brand, more conducive to stable device operation.

(2) internal seals used of Taiwan TTO.

(3) Internal use 304 stainless steel screws.

- Electrical control devices

Electrical control dual frequency control system, the inverter uses INVT products.

Other major components using joint venture, sole proprietorship or domestic famous brands.

- Control cabinet manufacturing standards

All control cabinet and switchgear for low voltage AC system in accordance with IEC439 technical requirements related to power system protection circuit installed to install and test, 380V power directly supplied electrical cabinets, cable entry for cable entry under control cabinet handle for spray plastic.

Main technical parameters:

|

Model |

Drum Dia. (mm) |

Drum length (mm) |

Length-Dia. Ratio |

Rotation speed(r/min) |

Separation factor(w2r/g) |

Capacity (m3/h) |

Motor power (Kw) |

Weight (kg) |

Dimension (mm) |

|

LW220x930 |

220 |

930 |

4.2 |

5000 |

2835 |

0.5-5 |

7.5 |

1200 |

2420x700x1010 |

|

LW300x1200 |

300 |

1200 |

4.0 |

4000 |

2550 |

1-5 |

7.5-11 |

1500 |

2680x830x1280 |

|

LW355x1600 |

355 |

1600 |

4.5 |

3800 |

2868 |

1-20 |

15-18.5 |

1850 |

3490x860x1200 |

|

LWS400X1200 |

400 |

1200 |

3.0 |

3650 |

3000 |

1-5 |

15-18.5 |

2500 |

2990x960x1205 |

|

LW400X1800 |

400 |

1800 |

4.5 |

3650 |

3000 |

2-25 |

15-22 |

2500 |

3890x1020x1205 |

|

LWS400X1800 |

400 |

1800 |

4..5 |

3650 |

3000 |

2-10 |

15-22 |

2500 |

3890x1020x1205 |

|

LW450x2000 |

450 |

2400 |

4.4 |

3450 |

3000 |

3-35 |

22-37 |

3000 |

4297X1080X1385 |

|

LWS450X2000 |

450 |

2600 |

4.4 |

3450 |

3000 |

3-35 |

22-37 |

3000 |

4297X1080X1385 |

|

LW500X2000 |

500 |

2000 |

4.0 |

3000 |

2500 |

5-45 |

30-37 |

3800 |

4330X1140X1470 |

|

LWS500X2000 |

500 |

2000 |

4.0 |

3000 |

2500 |

5-45 |

30-37 |

3800 |

4330X1140X1470 |

|

LW530X2280 |

530 |

2280 |

4.3 |

2900 |

2500 |

15-65 |

45-55 |

5000 |

4924X1170X1540 |

|

LWS530X2280 |

530 |

2280 |

4.3 |

2900 |

2500 |

15-65 |

45-55 |

5000 |

4924X1170X1540 |

|

LW580X2500 |

580 |

2500 |

4.3 |

2780 |

2500 |

20-80 |

55-75 |

6500 |

5205X1270X1540 |

|

LW650X2800 |

650 |

2800 |

4.3 |

2500 |

2270 |

20-110 |

75-90 |

7000 |

4300X1900X1350 |

|

LW760X3040 |

760 |

3040 |

4.0 |

2250 |

2150 |

30-150 |

90-132 |

8500 |

5000X2500X1500 |

Different type of the decanter centrifuge:

We provide you reliable and fast package and variety kinds of transportation way to insure you get the goods in time and safely.

1.We have professional person on line to p rovide you comprehensive.easy-understanding and detail information and technical data about the machine you interested;solve your confusions or questions about the machine

2.Advise you the most suitable type of machine according to your requirement for your reference

3.Arrange the schedule if you pay a visit to our factory.

4.Send our technical engineer to your country guide the installation,operation ,solve problems and so on if required.