2. It is resistant to ozone, UV resistance and other superior weather resistance, giving its long service life.

3. It has good adhesion, under normal conditions without primer. After curing the majority of building materials, such as glass, aluminum, steel and stone and other surfaces can obtain good adhesion.

4. It has a good compatibility with the silicone series of plastic, weathering adhesive and neutral silicone sealant.

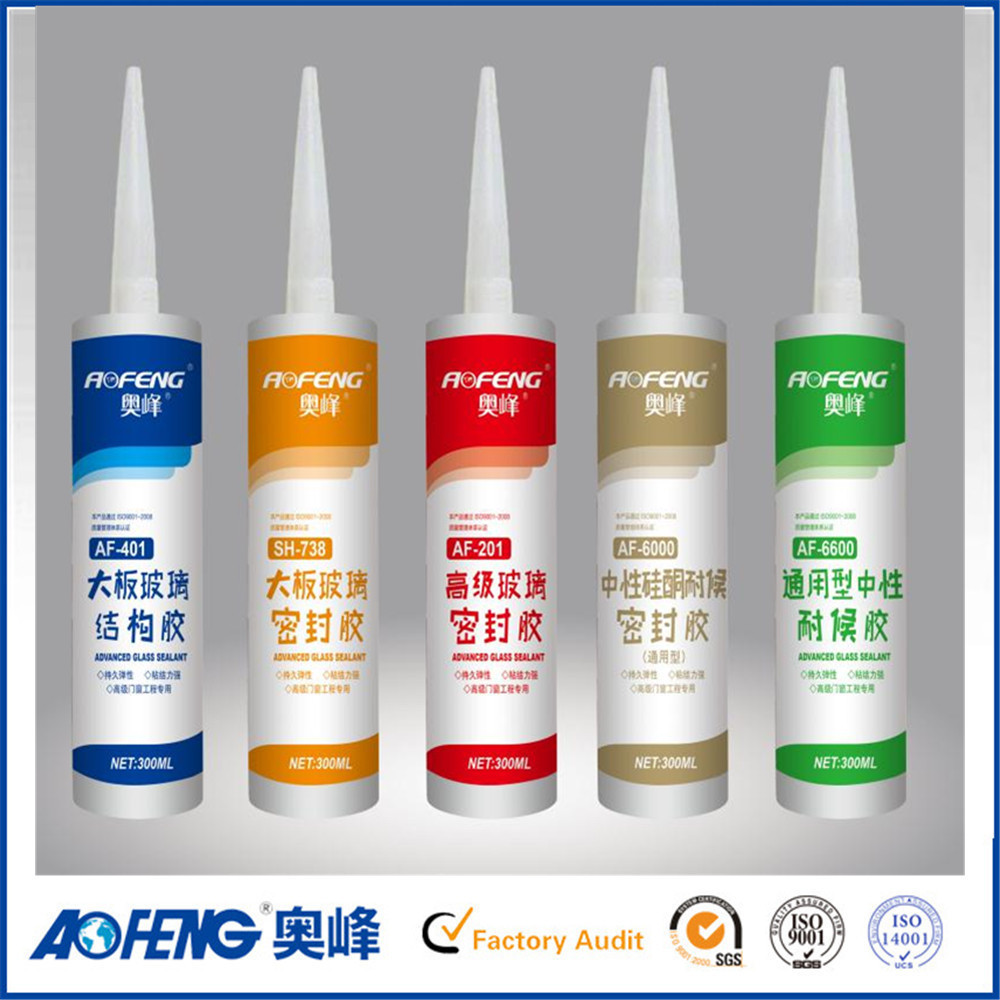

Product Features:

1. One-component, easy to use, in the 4 ℃ ~ 40 ℃ temperature range has good extrudability and thixotropy, with a

glue gun extrusion ok.2. Neutral curing, are not corrosive to metal, coated glass and other building materials, widely used.

glue gun extrusion ok.2. Neutral curing, are not corrosive to metal, coated glass and other building materials, widely used.

3.With 25 class of Displacement capacity, for the normal stretching and shear deformation of wall, the product can maintain the same performance, play an effective sealing effect.

4. Excellent resistance to climate aging, anti-aging, resistant to ultraviolet light, ozone resistance, water resistance, high and low temperature performance, after curing, at -30 ℃ low temperature will not become brittle, hardened or cracked, at + 90 ℃ high temperature will not be soft, degradation, and always maintain a good flexibility. Has excellent adhesion, after curing with most of the building materials to form a strong bond without the use of

primer.

5. With a good compatibility to other neutral silicone adhesive.