- Product Details

- {{item.text}}

Quick Details

-

Power:

-

3.0~22Kw

-

Weight:

-

1000

-

Dimension(L*W*H):

-

Standard

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Liquid Liquid Solid Separation

-

Name:

-

Centrifugal Decanter

-

Material:

-

Stainless Steel 304

-

Function:

-

Removing Impurities

-

Keyword:

-

Decanter centrifuge

-

Description:

-

Solid-liquid Separation Machine

-

Machine type:

-

Decanter Cantrifuge

-

Operation:

-

Automatic Continuous Operation

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

LPMIE

-

Voltage:

-

380V

-

Power:

-

3.0~22Kw

-

Weight:

-

1000

-

Dimension(L*W*H):

-

Standard

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Liquid Liquid Solid Separation

-

Name:

-

Centrifugal Decanter

-

Material:

-

Stainless Steel 304

-

Function:

-

Removing Impurities

-

Keyword:

-

Decanter centrifuge

-

Description:

-

Solid-liquid Separation Machine

-

Machine type:

-

Decanter Cantrifuge

-

Operation:

-

Automatic Continuous Operation

LW Series Food Industry Continuous Flow Automatic Discharge Decanter Centrifuge

3 Phase Decanter Centrifuge

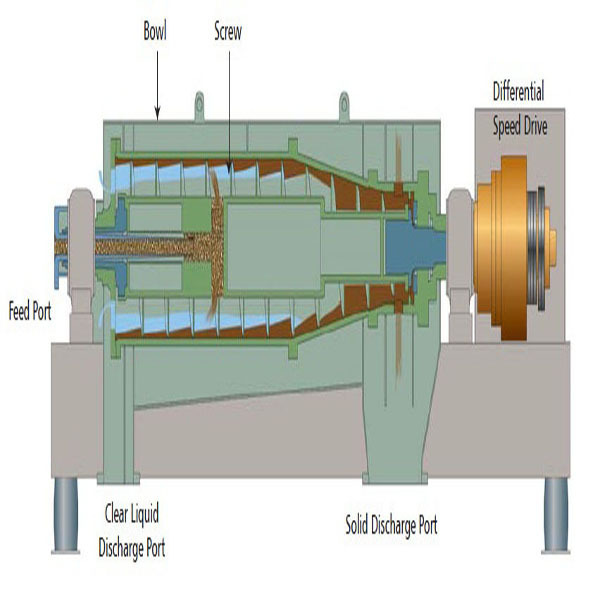

This kind of decanter as contra-flow type 3 phase decanter centrifuge, the whole centrifuge consist of bowl part, screw transporter, bearing seat, base seat, differential mechanism, base cover, main/assistant mort and electric control unit.

| Working Principle |

Working principle: suspension liquid feeding through pipeline, screw transporter outlet into bowl part, under high speed centrifugal force, solid phase settled on the surface of bowl wall, a certain differential mechanism occurs with the same rotating bowl, screw transporter delivery solid part to discharge hole, after separated, water phase will be taken out by centripetal pump, oil phase drain out from bowl.

The above speed discrepancy was occurs by differential mechanism, its shell part connected with bowl, main motor control rotating, differential mechanism output shaft connect with screw transporter, differential mechanism input shaft rotating controlled by sub motor, a certain gear ratio transferred to screw transporter, so that the solid part could be separated continuously, both main motor and sub motor start running controlled by double frequency inverter, different frequency control make equipment rotating in best way and get best separation results.

| Processing Drawing |

| Application Range |

Mainly Application:

- Separating and dewatering the industrial and domestic water.

- Wash, classification and dewatering for amylum.

- Dewatering for soybean, wheat.

- Dewatering for fish powder, fish meat.

- Dewatering for lees.

- Clarification for juice and dewatering for fruits.

- Separation and purification for animal and vegetable oil.

- Separation and purification for coal tar.

- Classification and dewatering for kaolin and graphite.

- Classification and dewatering for dyestuff and pigment.

- Float wash of extractive coal and dewatering of coal mud.

- Classification and dewatering for ore slurry.

| Main Features |

Main Features:

- the drum and scroll conveyor are made of stainless steel resisting corrosion

- the scroll conveyor was coated with wearable alloy or welded with alloy plate(optional)

- stepless speed regulation for the bowl

- step or stepless speed regulation for scroll’s differential speed.

- Safety protection: rotation rate detection over, vibration protection, motor overload and overheat protection, protection for scroll when zero differential speed occurs

- For the highly sticky materials, it can add the hydraulic differential gear to stabilize

| Equipment Photo |

LW355 x 1460 Decanter Centrifuge ( front view)

LW530 x 1800 Decanter Centrifuge ( front view)

LW355 x 1460 Decanter Centrifuge ( Side View)

LW355 x 1460 Decanter Centrifuge ( front view)

LW220 x 880 Decanter Centrifuge ( front view)

LW530 x 2120 Decanter Centrifuge ( side view)

| Technical Data |

Technical Parameters:

|

Models |

Bowl Dia. (mm) |

Bowl Speed (r/min) |

Centrifugal Force |

Motor Power(kw) |

Weight (kg) |

Dimension(mm) |

|

220x660 |

220 |

4800 |

2840 |

7.8-11 |

900 |

1650x1150x700 |

|

220x880 |

220 |

4300 |

2280 |

7.5-11 |

1000 |

1850x1200x750 |

|

300x1140 |

300 |

3750 |

2370 |

11-15 |

1500 |

2100x1300x650 |

|

355x1160 |

350 |

4000 |

3100 |

22 |

2020 |

3067x920x1060 |

|

355x1460 |

350 |

4000 |

3100 |

22 |

2200 |

3365x920x1060 |

|

400x1200 |

400 |

3500 |

2750 |

18.5-22 |

2500 |

2400x1650x900 |

|

420x1680 |

420 |

3600 |

3000 |

22 |

2430 |

3320x1000x1060 |

|

450x1350 |

450 |

3500 |

3080 |

30 |

2230 |

3750x1090x1250 |

|

450x1800 |

450 |

3500 |

3080 |

30-37 |

3500 |

4200x1090x1250 |

|

530x1800 |

530 |

3200 |

3040 |

45-55 |

3920 |

4565x1230x1350 |

|

530x2120 |

530 |

3200 |

3040 |

45-55 |

4200 |

4885x1230x1350 |

|

730x2400 |

730 |

2400 |

2350 |

110-132 |

9300 |

5500x3200x1450 |

|

1120x3300 |

1100 |

1400 |

1200 |

160-200 |

15700 |

7000x3600x1780 |

You may also interested in other type Centrifuge, Please visit the following website or picture as:

Tubular Centrifuge Peeler Centrifuge

Disc Ceentrifuge Decanter Centrifuge

Top Discharge Centrifuge Marine Oil Separator

For detialed technical specification of such equipment, please contact me in the following items:

1. Contact person name: Ms. Daisy Liu

2. Contact e-mail address: daisy (at) lpmie.net