|

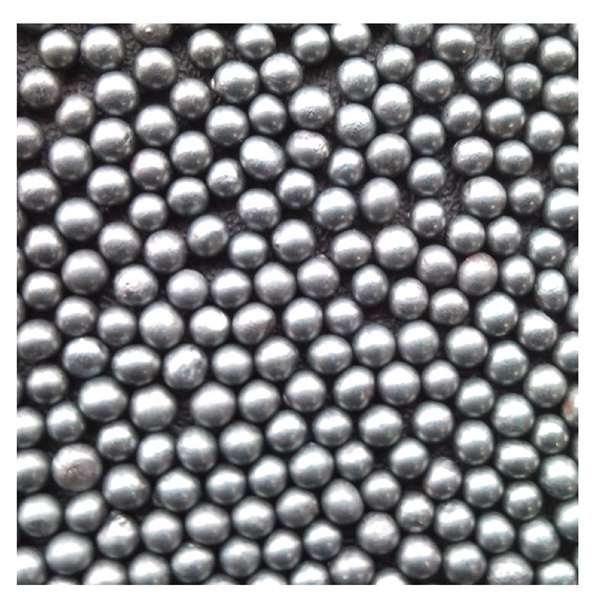

Steel Shot

|

They are widely used in industries. Different grain sizes are suitable for different purposes.

|

|

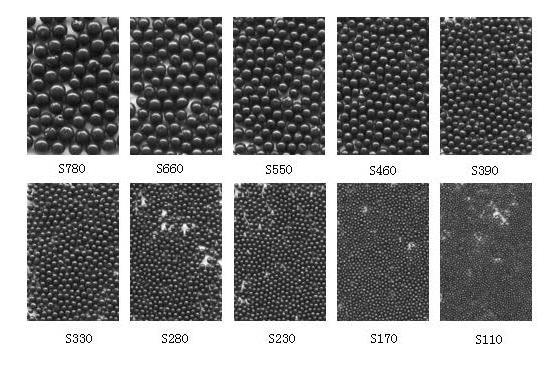

SS-2.5

SS-2.0

|

Sand and rusts removing of large-sized cast iron, cast steel, steel structures, large-sized forging and surface treatment of oxidized workpieces.

|

|

SS-1.7

SS-1.4

|

Sand-removing of large and medium sized castings, deoxidization of forgings, heat-treated pieces, steel plates, steel pipes, sections and steel structures, surface treatment before plating.

|

|

SS-1.2

SS-1.0

|

Sand-removing of small and medium sized castings, rust-removing and intensification of forgings, heat-treated pieces, steel plates, steel pipes, sections and steel structures, surface treatment before plating, cutting of rocks.

|

|

SS-0.8

SS-0.6

|

Sand-removing and deoxidization of small-sized castings, forgings, heat-treated pieces, aluminum-copper alloy castings, steel plates, steel pipes, sections and steel structures, surface intensification of springs and chains, cutting of rocks, grinding processing.

|

|

SS-0.5

SS-0.3

|

Sand-removing and rust-cleaning of alloy castings, thin plates, strip steel, and small-sized stainless steel castings, intensification of springs, surface treatment before plating, improving roughness, enhancing adhesiveness.

|