- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

37000 KG

-

Product name:

-

tire steel wire separator tyre bead cutting machine to grind tire into

-

Raw material:

-

Used Tire

-

Application:

-

Waste Tire Processing Machinery

-

Capacity:

-

200-1000kg/h

-

Usage:

-

rubber tile/reclaimed rubber/waterproof

-

Keyword:

-

Tire Shredder Rubber Crusher

-

Advantage:

-

Environmental Friendly

-

End product:

-

20 -100 Mesh Rubber Powder

-

Operation:

-

2-4 Persons

-

Power(W):

-

45kw

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Shuliy

-

Voltage:

-

220V/380V

-

Power (kW):

-

7.5 kW

-

Weight (KG):

-

37000 KG

-

Product name:

-

tire steel wire separator tyre bead cutting machine to grind tire into

-

Raw material:

-

Used Tire

-

Application:

-

Waste Tire Processing Machinery

-

Capacity:

-

200-1000kg/h

-

Usage:

-

rubber tile/reclaimed rubber/waterproof

-

Keyword:

-

Tire Shredder Rubber Crusher

-

Advantage:

-

Environmental Friendly

-

End product:

-

20 -100 Mesh Rubber Powder

-

Operation:

-

2-4 Persons

-

Power(W):

-

45kw

-

Certification:

-

CE ISO

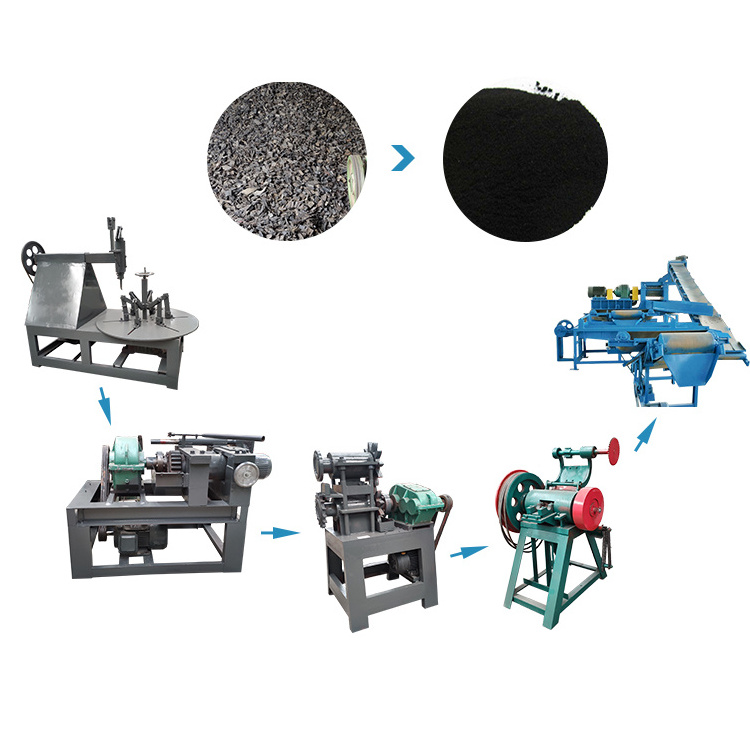

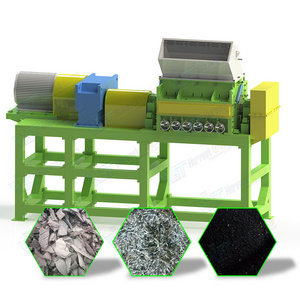

Rubber Powder Making Line

Detailed Information of Rubber Powder Making Line

Rubber Powder Making Line, as the kind of tire recycling equipment, is environmentally friendly.Due to the number of waste tires is gradually increasing every year, we produced the Rubber Powder Production Line in order to make full use of these tires, not only can relieve environmental pressure, but also create the economy value. This is the kind of “turn waste into wealth”.For our Rubber Powder Making Line, we have different solutions according to different tyre sizes, and it has high output, like 26mesh rubber powder, the capacity can reach 36T/day.

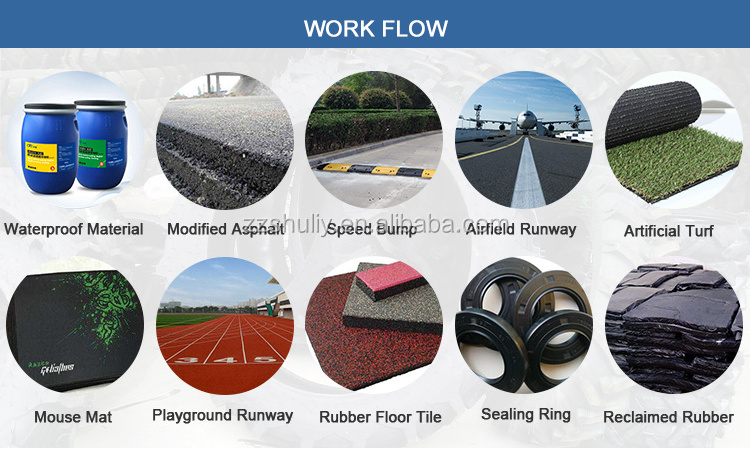

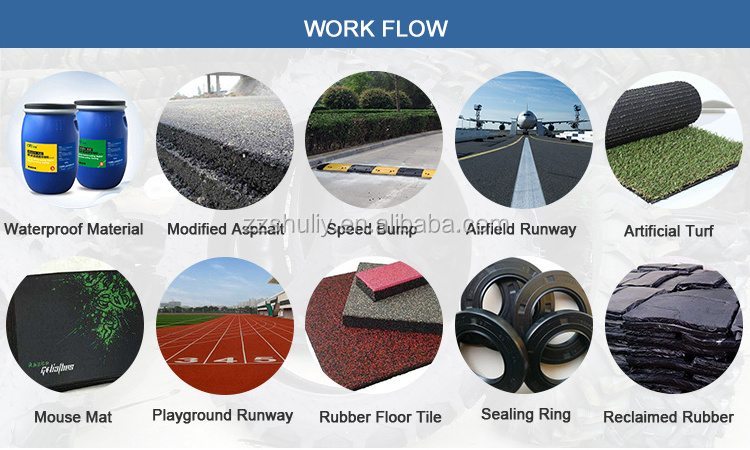

Application of Rubber Powder Making Line

The finished rubber granules and rubber powder can be widely used in stadium runway, school playground, modified asphalt and also can be made into rubber pipe, rubber overshoes, rubber conveyor belt, rubber floor tile and deceleration strip by high temperature and high-pressure desulfurization.

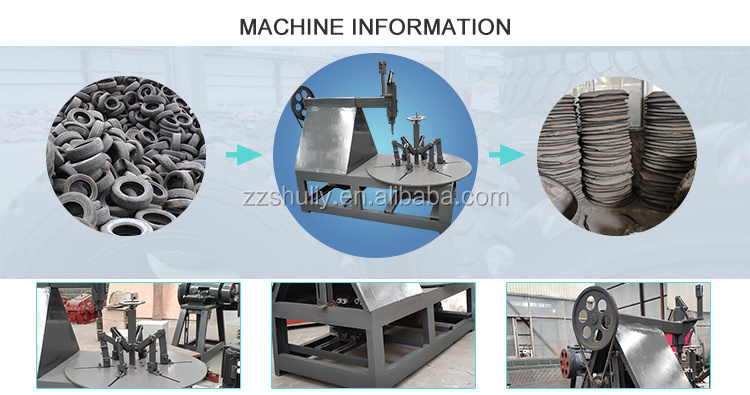

Machine Information of Rubber Powder Making Line

1.Tyre circular cutter

Place the tire on the disc platform, rotate the middle handwheel, the three-jaw card holder will firmly clamp the inner ring of the tire, start the power supply, rotate the working platform, and the cutter slowly cut into the tire until the side of the tire is cut.

2.Tyre wire separator

This machine is mainly used to separate the rubber on the steel ring of the tire from the bead ring to obtain a complete steel wire.

This machine cuts the tires whose steel wire has been removed to strip, and the width of the strip is adjustable. The two disc knives are made of special materials that are hard and durable and can be used for repeated grinding.

4.Rubber block cutter

The rubber tire block cutter machine cuts the long strips into pieces, and the cutters are alloy. The daily output is nearly 9-16 tons.

5.Rubber powder machine

The machine to grind tire into rubber powder is made of conveyor belt, vibrating screen , Magnetic separator.It is suitable for crushing rubber blocks into rubber powder and rubber particles.The roller and bearing are made of high wear-resistant material and have long service life.

|

Model |

SL350 |

SL400

|

SL450 |

SL560 |

SL560D |

|

Length of roll diameter(mm) |

300*500 |

400*600 |

450*760 |

560*800 510*800 |

560*800 |

|

Liner velocity of front roller (m/min) |

26.2 |

34.5 |

38.0 |

38.6 |

42.5 |

|

Roller speed ratio |

1:2.5 |

1:2.5 |

1:2.5 |

1:2.5 |

1:2.5 |

|

The biggest roller spacing(mm) |

8 |

8 |

8 |

8 |

8 |

|

Motor power(kw) |

30 |

45 |

55 |

75 |

132 |