As customer request and market demand ,we provide the better solution for the final product package ,

We have various kinds of options .Labeling machine have the PVC sleeve label ,BOPP hot glue label,Adhesive stick label ,Wet glue label ,and packing machine have the film shrink machine and carton box package.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

+/-1%, 1% (liquid Level)

-

Voltage:

-

220V / 380V /450V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ALPS

-

Dimension(L*W*H):

-

3.8*2.3*2.8

-

Weight:

-

5000 KG

-

Function:

-

Filling labeling packing

-

Filling material:

-

Carbonated drink / water

-

Material:

-

SUS304 / 316

-

Filling volume:

-

200-2000ml

-

Filling type:

-

Isobaric filling

-

Filling heads:

-

12/16/24/32 heads

-

Control:

-

PLC (SIEMENS)

-

Motor:

-

SEW (Germany)

-

Suitable bottle:

-

PET bottle / Glass bottle

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Beer, Milk, Water, Carbonated beverage

-

Filling Accuracy:

-

+/-1%, 1% (liquid Level)

-

Voltage:

-

220V / 380V /450V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ALPS

-

Dimension(L*W*H):

-

3.8*2.3*2.8

-

Weight:

-

5000 KG

-

Function:

-

Filling labeling packing

-

Filling material:

-

Carbonated drink / water

-

Material:

-

SUS304 / 316

-

Filling volume:

-

200-2000ml

-

Filling type:

-

Isobaric filling

-

Filling heads:

-

12/16/24/32 heads

-

Control:

-

PLC (SIEMENS)

-

Motor:

-

SEW (Germany)

-

Suitable bottle:

-

PET bottle / Glass bottle

Complete PET Bottle Beverage Isobaric Filling Machine Carbonated Soda Soft Drink Production Line

*We supply complete solution for the Carbonated beverage filling plant ,including Water treatment system / Carbonated beverage mixing system / Washing filling capping machine / Code sprayer / Pasteurizer tunnel / Automatic labeling machine / Automatic packing machine / Automatic Palletizer system

|

Technical parameter : soda drink filling line

|

|

|

|

|

|

|

||||||

|

Model

|

DCGF14-12-5

|

DCGF18-18-6

|

DCGF24-24-10

|

DCGF32-32-10

|

DCGF40-40-12

|

|

||||||

|

Capacity(for 500ml)

|

2000-3000

|

3000-5000

|

5000-7000

|

8000-10000

|

12000-15000

|

|

||||||

|

Suitable bottle shapes

|

PET circular

|

|

|

|

|

|

||||||

|

Bottle diameter(mm)

|

Dia50-Dia115mm

|

|

|

|

|

|

||||||

|

Bottle height (mm)

|

160-320mm

|

|

|

|

|

|

||||||

|

Filling type

|

Isobaric filling

|

|

|

|

|

|

||||||

|

Filling pressure

|

<0.4 Mpa

|

|

|

|

|

|

||||||

|

Rinsing water pressure

|

>0.06Mpa <0.2Mpa

|

|

|

|

|

|

||||||

|

Application

|

soda drink filling line

|

|

|

|

|

|

||||||

|

Total power (KW)

|

4.4kw

|

5.2kw

|

6.2kw

|

7.5kw

|

8.2kw

|

|

||||||

|

Overall dimensions

|

2.5*1.9m

|

2.8*1.9m

|

3.2*2.2m

|

3.4

*

2.5m

|

4.8*2.3m

|

|

||||||

|

Height

|

2.3m

|

2.5m

|

2.5m

|

2.5m

|

2.5m

|

|

||||||

|

Weight(kg)

|

3000kg

|

4500kg

|

6000kg

|

8500kg

|

10000kg

|

|

||||||

Different filling capacities

DCGF18-18-6 Bottle Carbonated beverage Filling Line Capacity:3000-5000 bottles per hour.

DCGF24-24-8 Bottle Carbonated beverage Filling Line Capacity:50000-7000 bottles per hour.

DCGF32-32-10 Bottle Carbonated beverage Filling Line Capacity:8000-10000 bottles per hour.

DCGF40-40-12 Bottle Carbonated beverage Filling Line Capacity:12000-15000 bottles per hour

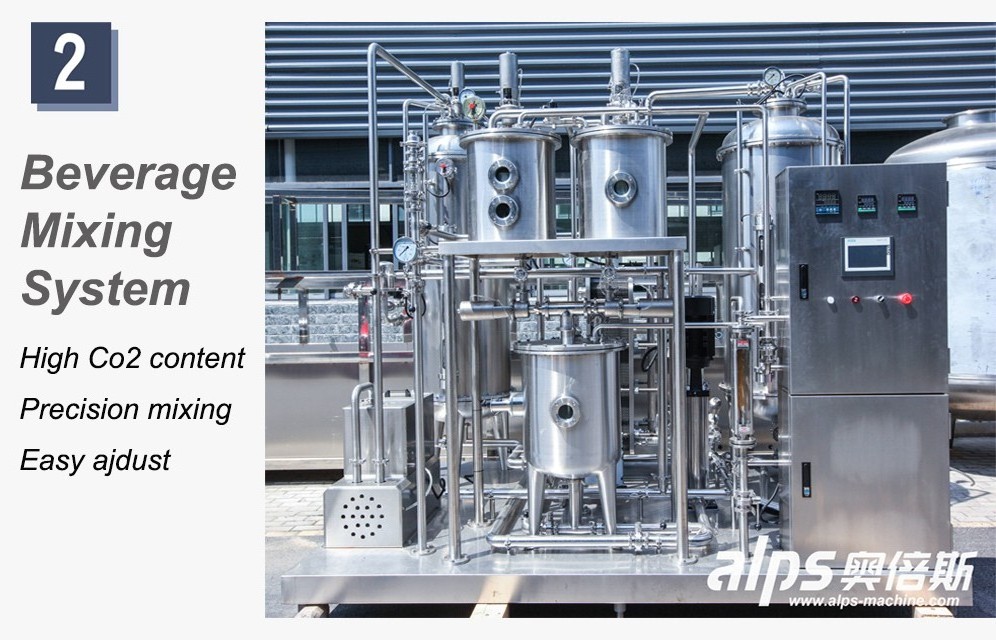

Carbonated beverage mixing system structure reasonable, =mix precision is high, CO2 mixes fully, has two times of cooling, two carbonation merits. Mainly is suitable for kinds of carbonated drink's mix processing, also may use in the paste drink, the fermentation drink and so on other soft drinks' mix processing.

Main Features

*Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

* Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

* The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

*High-speed large Isobaric filling valve, filling fast, filling accurate and no liquid lose.

*Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

*Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

|

Name

|

Brand

|

Area

|

|

PLC

|

Siemens

|

Germany

|

|

Inverter

|

Siemens

|

Germany

|

|

Contactor

|

Siemens

|

Germany

|

|

Touch screen

|

Siemens

|

Germany

|

|

Inverter

|

Siemens

|

Germany

|

|

Motor

|

ABB

|

Swiss

|

|

Pneumatic parts

|

FESTO

|

Germany

|

|

Electrical parts

|

Schneider

|

France

|

We design the factory layout based on customer factory sizes,whole line design is based on famous brand motors and automatic lubricant system ,and with less power consumption ,and save space .

This machine is a fully automatic, high intelligent, stable and reliable blowing machine, with simple structure, and low energy consumption. It is very popular and well used in food, beverages, cosmetics, pharmaceutical industry.

Pure Water line

Like mineral water,still water,flavoured water,oxygen water ...

Capacity :1000bph~20000bph

Fruit Juice Line

Like Fruit juice ,NFC juice , juice with pulp ...

Capacity:500bph~30000bph

Beer filling line

Like PET bottle beer ,Glass bottle beer ,Can beer ...

Capacity:500bph~20000bph

Different types of processing units, such as water jet cutter, plasma cutter, laser cutter, CNC machine from Taiwan chevalier & korea daewoo, ensure the precision of parts.

*International certification, National Certificate of equipment verification, and more than 30 invention patents

Verification Certificates of equipments: ISO9001:2001; CE Certificate , SGS , COC , TUV National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark registration,etc.

*The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechanical stability.

*Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

*The engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers' requirements to save space.

*Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

1.Q:Are you a factory or trading company?

A:We are a factory, professional water treatment system manufacturer and small bottle water filling & packing machinery with about 10 years experience. Factory covers an area of 12000 square. There have been more than 50 countries use our products.

2.Q:Where is your factory located? How can I visit there?

A:Our factory is located in Donglai town,Zhangjiagang city,Jiangsu province,China. about 2 hours away from PVG Airport . All clients are warmly welcome to visit us !

3.How about installation ?

We will send our engineers to your factory to install the machines and train your staff how to operate the machines. Customer pay air tickets go and back,accommodation and USD100 / day/person.

4.Q:How long is the warranty of your equipment?

A:2 years warranty after receipt check upon delivery.And we will comprehensively provide you all kinds of technical support services in after-sale service

5.Q:What is the features of our company?

A: We provide turnkey project for customers, including sale and after-sale service; complete production line equipment supply; bottle design; layout programs provide; or provide auxiliary materials purchasing agent supplier information; equipment overseas installation and commissioning; operator training; etc