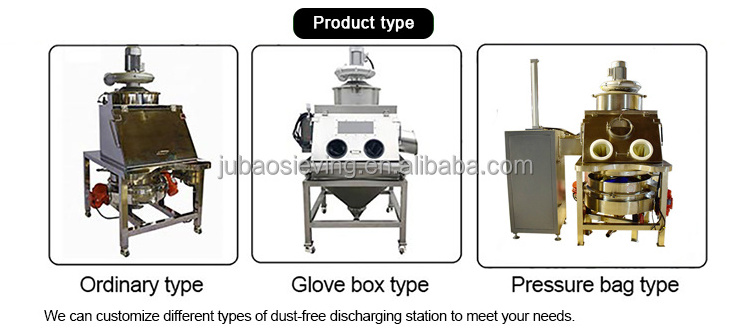

Advantages

1.

Avoid material dust flying everywhere

2. Long servicing life;

3. Sell well at home and broad;

4.

Reduce labor intensity;

5. Good weld;

6.

Widely used in powder, particle, fiber

materials.