- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LANPHAN

-

Product Name:

-

Solvent Recovery Machine

-

Total Volume:

-

28L-330L

-

Charging Volume:

-

20L-225L

-

Recovery Time:

-

about 4~5 hours

-

Heating Temperature:

-

50~210℃

-

Coolong Method:

-

air cooling

-

Environment Temperature:

-

5~30℃

-

Recovery Rate:

-

≥95%

-

Power:

-

220V/50HZ

Quick Details

-

Weight (KG):

-

122

-

Marketing Type:

-

Hot Product 2022

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

LANPHAN

-

Product Name:

-

Solvent Recovery Machine

-

Total Volume:

-

28L-330L

-

Charging Volume:

-

20L-225L

-

Recovery Time:

-

about 4~5 hours

-

Heating Temperature:

-

50~210℃

-

Coolong Method:

-

air cooling

-

Environment Temperature:

-

5~30℃

-

Recovery Rate:

-

≥95%

-

Power:

-

220V/50HZ

Solvent Recovery Machine

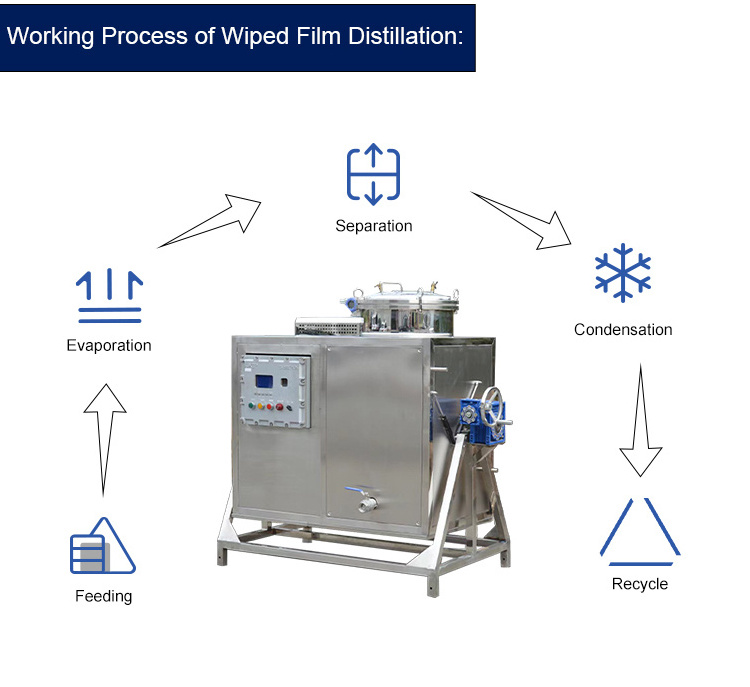

Solvent recovery machine is a special equipment to regenerate and recycle waste organic solvents. Discarded or colored waste solvents (such as diluent, EA, CH2Cl2, xylene and most of the organic solvents used for cleaning) are reduced to clean solvents through this equipment, and then put into production or experiments to achieve multiple use of solvents.

| Product Model | LPA-20 | LPA-30 | LPA-60 | LPA-200 |

| Total Volume | 28 L | 46 L | 80 L | 330 L |

| Charging Volume | 20 L | 32 L | 60 L | 225 L |

| Recovery Time | about 3 hours | about 4~5 hours | about 4~5 hours | about 4~5 hours |

| Heating Temperature | 50~210℃ | 50~210℃ | 50~210℃ | 50~210℃ |

| Coolong Method | air cooling | air cooling | air cooling | air cooling |

| Environment Temperature | 5~30℃ | 5~30℃ | 5~30℃ | 20~50℃ |

| Charging Method | Manual Charging | Manual Charging | Manual Charging | Manual Charging |

| Discharging Method | Dumping | Dumping | Dumping | Dumping |

| Recovery Rate | ≥95% | ≥95% | ≥95% | ≥95% |

| Power | 220V/50HZ | 220V/50HZ | 220V/50HZ | 3P/380V/50HZ |

| Dimension | 790×535×1240 | 825×638×1280 | 587×827×1480 | 2100×1130×1950 |

| Net Weight | 93 KG | 122 KG | 136 KG | 629 KG |

Waste or colored waste solvents (such as diluent, EA, CH2Cl2, xylene and most of the organic solvents used for cleaning) are reduced to cleaning solvents through this equipment, and then put into production or experiments to achieve multiple use of solvents.