Reverse Osmosis or (RO) can be described as a procedure whereby pure water and contaminants is divided via a semi-permeable membrane(s) with very fine pores. This method is a necessary technique employed in the majority of water purification systems.

Reverse Osmosis is considered to be a highly effective approach to eliminating water impurities, such as Toxic Heavy Metals i.e.Lead and Radium, Mercury, Chlorinated Pesticides, organic matters, Turbidity & Dissolved Solids, bacteria, virus.

RO system is widely used in water treatment, purification for tap water, well water, underground water, borehole salty water, brackish water and seawater, pure water and ultra-pure water production. Application area such as, food processing, bottled drinking water, home use drinking water, power stations, electronic industries, cosmetics production. It is a key equipment for pure water plant and ultrapure water equipment.

- Product Details

- {{item.text}}

Quick Details

-

Material:

-

stainless steel, 304 Stainless Steel

-

Weight:

-

500kg

-

Power:

-

1.5

-

Weight (KG):

-

500 kg

-

Product name:

-

water filter system machine

-

Capacity:

-

500L-50000L

-

Pump:

-

CNP

-

Working pressure:

-

1-6bar

-

RO membrane:

-

4040/8040

-

Stage:

-

5/6/7/8/9 Stage

-

Pressure tank:

-

3 Gallon Plastic Tank (3.2G Metal Tank / 4 Gallon Plastic Tank)

-

Filter:

-

6-stage Reverse Osmosis Filtration

-

Filter material:

-

PP Cotton+Activated Carbon+RO

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZYL

-

Material:

-

stainless steel, 304 Stainless Steel

-

Weight:

-

500kg

-

Power:

-

1.5

-

Weight (KG):

-

500 kg

-

Product name:

-

water filter system machine

-

Capacity:

-

500L-50000L

-

Pump:

-

CNP

-

Working pressure:

-

1-6bar

-

RO membrane:

-

4040/8040

-

Stage:

-

5/6/7/8/9 Stage

-

Pressure tank:

-

3 Gallon Plastic Tank (3.2G Metal Tank / 4 Gallon Plastic Tank)

-

Filter:

-

6-stage Reverse Osmosis Filtration

-

Filter material:

-

PP Cotton+Activated Carbon+RO

zhongyilong: A Trusted Name in filling packing Business

we provides the best filling packing euioment for business, home, and industry. 0ur business scope includes the preparation of laboratory purewater, the provision of household drinking water, small water plants/mineral water production busine and so on. We have always built relationships throughcuality and efhciency. Al of our products are made with the highest quality components to provide you with only the best filling packing equipment.Contact us for your Plant project production equipment solution!

Select us for your solution Tailor made, provide you complete turnkey solution zhongyilong’s expertise in liquid packaging ensures the perfect combination of process design and product-line engineering. With the established process design system of various liquid packaging fields such as beverages, dairy products, liquors, condiments, and daily chemical products, we can provide customized turnkey solution for your project considering different packaging forms and specific factory layouts. our company can provide a full set of production line equipment and has a very experienced team of overseas installation and commissioning, private machinery look forward to working with you win-win cooperation。

Product Description

hot sell 500Lwater treatment machinery equipment reverse osmosis pure water machine commercial alkaline water machine in china

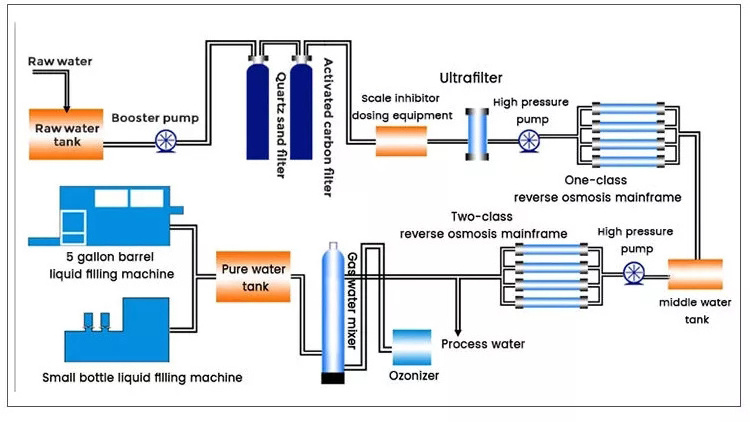

Description of reverse osmosis water treatment plant

Water treatment wording process:

Raw water pump→ Quartz sand filter→ activated carbon filter→ Water softener→security filter → high pressure pump→Reverse osmosis system→UV/Ozone generator→ pure water tank

Raw water pump→ Quartz sand filter→ activated carbon filter→ Water softener→security filter → high pressure pump→Reverse osmosis system→UV/Ozone generator→ pure water tank

Product specification:

1. Raw water pump-- provide the pressure to quartz sand filter/active carbon filter.The flow part of the pump body is stamped and welded by corrosion-resistant stainless steel, and the shaft seal adopts cemented carbide and fluorine rubber mechanical seals, making the pump suitable for mildly corrosive media.

2. Quartz Sand filter--get rid of turbidity,suspended matter, organic matter, colloid, etc.

3. Active Carbon filter--Remove the color, free chloride, organic matter, harmful matter, etc.

4. Softener--exchange "ions" of calcium and magnesium with the most common and easiest method.

5. Cartridge filter--prevent large particles into RO membrane, accuracy is 5um.

6. High pressure pump--Provide the high pressure to RO membrane.The power pillar for the operation of the whole set of equipment adopts the well-known domestic brand Nanfang Pump Industry, which has lasting and stable performance and long durability.

7. RO reverse osmosis membrane-- main part of the plant. Reverse osmosis water production: 1m3/h,desalination rate:96~99%, System water utilization:≥ 60%.Choose the highest standard selection component in the industry-DOW imported membrane to ensure the stability of the water quality of the mixed water and the maintenance cost of the equipment.

8. UV/ozone generator-- kill bacteria in the water .

9.EDI-- Use the selectivity permeation effect on anion and cation by the anion and cation exchange membrane, and exchange effect. on ion by ion exchange resin, to get high purity water.

Specification

|

Product type

|

Productivity

(L/H)

|

Standard rated power(Kw)

|

RO Membrane

|

Material

|

Weight

(kg)

|

|

RO-500L

|

500L

|

380V/50HZ

1.5Kw

|

4040 RO

2pcs of filter cartridges

|

SUS304

|

185

|

|

RO-1000L

|

1000L

|

380V/50HZ

1.65Kw

|

4040 RO

4pcs of filter cartridges

|

SUS304

|

450

|

|

RO-2000L

|

2000L

|

380V/50HZ

2.95Kw

|

4040 RO

8pcs of filter cartridges

|

SUS304

|

560

|

|

RO-3000L

|

3000L

|

380V/50HZ

5.1Kw

|

4040 RO

12pcs of filter cartridges

|

SUS304

|

680

|

|

RO-4000L

|

4000L

|

380V/50HZ

7Kw

|

8040 RO

4pcs of filter cartridges

|

SUS304

|

850

|

|

RO-5000L

|

5000L

|

380V/50HZ

8Kw

|

8040 RO

5pcs of filter cartridges

|

SUS304

|

980

|

|

S/N

|

Commodity name

|

Description/Application

|

Remark

|

|

1

|

Raw water tank

|

Store water, buffering pressure, overcome instability of supplying water by pipe, ensure to supply water stably and continuously for whole system

|

Customer provide for themselves, because big size will result in expensive freight.

|

|

2

|

Raw water pump or called booster pump

|

Provide needed pressure for every pretreatment filter

|

We can provide CNP pumps or Grundfos pumps

|

|

3

|

Mechanical filter or called quartz sand filter or sand filter

|

We use fiber glass or stainless steel vessel as housing, fill quarts sand, it can filter big particles impurities, suspended substances, colloids etc.

|

We use China brand or WAVE CYBER brand

|

|

4

|

Activated carbon filter

|

We use fiber glass or stainless steel vessel as housing, fill activated carbon, remove color, odor, residual chlorine and organics substances.

|

We use China brand or WAVE CYBER brand

|

|

5

|

Water softener, demineralizer, or called Na+ exchanger

|

Adopt cation resin to soften water, cation resin will absorb Ca2+, Mg2+(main elements for composing scale), reduce hardness of raw water, System can make resin intelligently regenerate, recycling

|

|

|

6

|

Antiscalant dosing system or PH regulating system

|

Dosing antiscalant into feed water, prevent the ro membranes from blocking, prolong the lifetime of RO membranes. Regulating PH to suitable range.

|

Italy SEKO dosing pump or German Prominent

|

|

7

|

Security filter or pp filter, or called PP sediment filter

|

prevent large particles, bacteria, viruses into RO membrane, accuracy is 5µm

|

Stainless steel housing or PVC housing

|

|

8

|

High pressure pump

|

Provide needed working pressure for RO system, ensure production capacity of pure water.

|

CNP pump, Grundfos optional

|

|

9

|

RO(reverse osmosis) system

|

Can remove particles, colloids, organic impurities, heavy metal ions, bacteria, virus, heat source etc. harmful substances and 99% dissolved salts.

|

RO membranes USA Filmtec Dow

|

|

10

|

CIP cleaning system

|

Cleaning RO membranes with chemicals

|

CNP pumps

|

|

11

|

Sterilizer device

|

UV sterilizer or ozone generator

|

BNP ozone machine, USA Hanovia UV bulb

|

Application

Application Area

1)Food, beverage, drinking water, bottled drinking water, sachet/pouch packing pure drinking water treatment

2)Chemical industry, industry pure water treatment

3)Electronic industry, semiconductor industry ultrapure water treatment

4)Electroplating and leather industry waste water treatment

5)Brackish water desalination, sea water desalination, metallurgy and light industry pure water treatment

6)Cosmetic products, car battery, liquid fertilizer production pure water treatment

7)Edible cube ice, tube ice etc.

8)School, hotel, hospital, laboratory, surface treatment, hydraulic test, industrial boiler, power station boiler, high pressure

boiler water treatment

2)Chemical industry, industry pure water treatment

3)Electronic industry, semiconductor industry ultrapure water treatment

4)Electroplating and leather industry waste water treatment

5)Brackish water desalination, sea water desalination, metallurgy and light industry pure water treatment

6)Cosmetic products, car battery, liquid fertilizer production pure water treatment

7)Edible cube ice, tube ice etc.

8)School, hotel, hospital, laboratory, surface treatment, hydraulic test, industrial boiler, power station boiler, high pressure

boiler water treatment

Related Products

About us

FAQ

Q: Are you a factory? How many workers do you have?

●Yes, we are factories.

Q. How to ensure the safety of your funds and timely delivery?

● Guarantee the on-time delivery and quality of the equipment you want to purchase through Alibaba's guarantee service.

Q. How to ensure quality?

● In order to ensure the accuracy of each part, we have equipped a variety of professional processing equipment and accumulated professional processing methods over the years.

● Each component before assembly shall be strictly controlled by the inspector.

● Each assembly is in the charge of a master with more than 5 years of work experience

● After all equipment is completed, we will connect all machines and run the whole production line for at least 12 hours to ensure stable operation of the customer's factory

Q. After sales service of the machine?

● After the production is completed, we will debug the production line, take photos and videos and send them to customers via email or instant tools

● After commissioning, we will pack and ship the equipment in standard export packaging.

● According to the customer's requirements, we can arrange engineers to go to the customer's factory

for installation and training.

Q. How to ensure the safety of your funds and timely delivery?

● Guarantee the on-time delivery and quality of the equipment you want to purchase through Alibaba's guarantee service.

Q. How to ensure quality?

● In order to ensure the accuracy of each part, we have equipped a variety of professional processing equipment and accumulated professional processing methods over the years.

● Each component before assembly shall be strictly controlled by the inspector.

● Each assembly is in the charge of a master with more than 5 years of work experience

● After all equipment is completed, we will connect all machines and run the whole production line for at least 12 hours to ensure stable operation of the customer's factory

Q. After sales service of the machine?

● After the production is completed, we will debug the production line, take photos and videos and send them to customers via email or instant tools

● After commissioning, we will pack and ship the equipment in standard export packaging.

● According to the customer's requirements, we can arrange engineers to go to the customer's factory

for installation and training.

Hot Searches