- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

201-177-9

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Hinah

-

Model Number:

-

HNPCP

-

Product Name:

-

Powder coating powder

-

Application:

-

Surface coating

-

Type:

-

Powder

-

Material:

-

Thermosetting resin

-

MOQ:

-

200kg

-

Packing:

-

Plastic Bag

-

Color:

-

Customized

-

Service:

-

2 years warranty after purchase

Quick Details

-

CAS No.:

-

9003-01-4

-

Other Names:

-

metal powder coating

-

MF:

-

Mixture

-

EINECS No.:

-

201-177-9

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Hinah

-

Model Number:

-

HNPCP

-

Product Name:

-

Powder coating powder

-

Application:

-

Surface coating

-

Type:

-

Powder

-

Material:

-

Thermosetting resin

-

MOQ:

-

200kg

-

Packing:

-

Plastic Bag

-

Color:

-

Customized

-

Service:

-

2 years warranty after purchase

Products Feature

The company has a complete range of products, which are widely used in transportation facilities, aluminum profiles, metal cabinets, hardware tools, household appliances, storage facilities, sports products, metal castings, engineering machinery, building materials, logistics equipment, oil and gas pipelines and many other fields.

We are continuously seeking improvements and innovation for our products and services, while we constantly strive to find new and better ways to meet our customers’ needs and exceed their expectations. For us, your satisfaction is what matters the most that is why we will provide the best value through continuously improving our processes and cost structure.

|

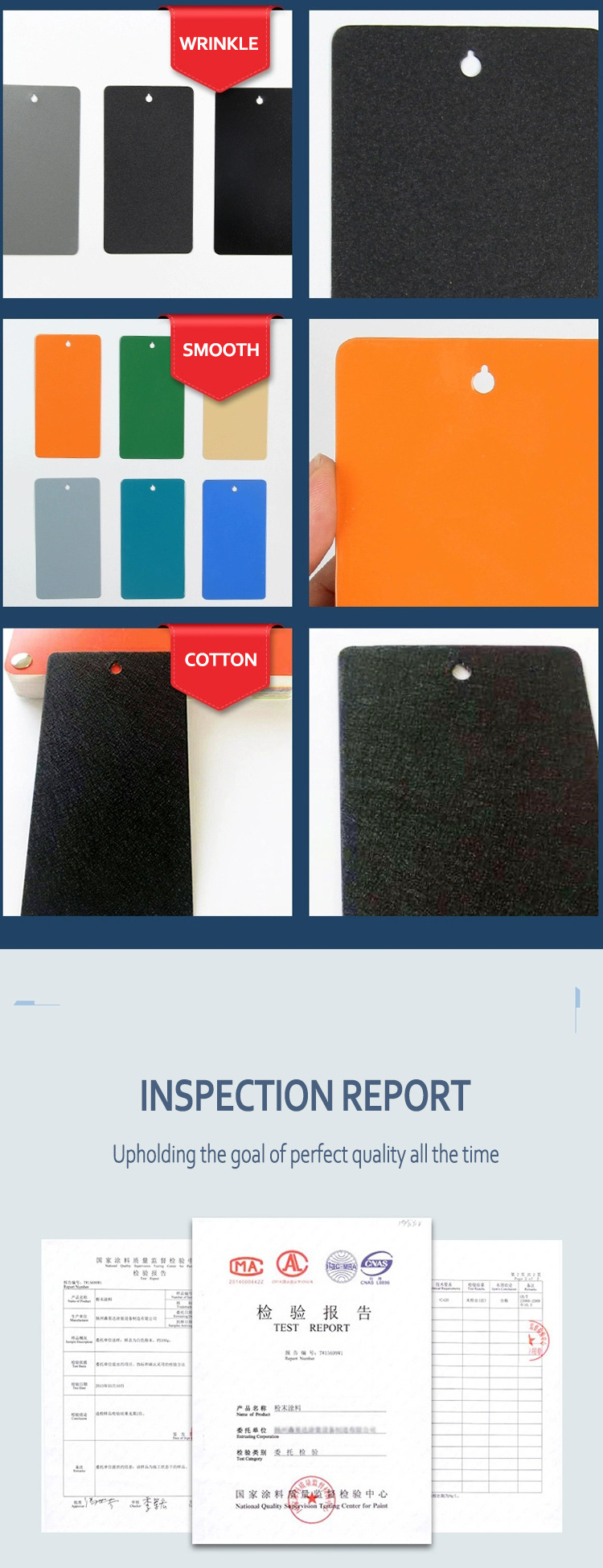

Coating Performance

|

|

|

|

|

||||

|

Test Items

|

Inspection Standards

|

|

Test Indicators

|

|

||||

|

|

|

|

High Light

|

Glazed/ Matte /Low Light

|

||||

|

Impact Resistance

|

ISO6272

|

GB/T1732-1993

|

50kg/cm

|

40kg/cm

|

||||

|

Cupping Test

|

ISO1520

|

GB/T9753-1988

|

8mm

|

7mm

|

||||

|

The Ddhesion (Grid Method)

|

ISO2409

|

GB/T9286-1998

|

0

|

|

||||

|

Bending

|

ISO1519

|

GB/T6742-1986

|

2mm

|

3mm

|

||||

|

Pencil Hardness

|

ASTMD3363

|

GB/T6739-1996

|

1H-2H

|

|

||||

|

Salt Spray Test

|

ISO7253

|

GB/T1771-1991

|

>500 hours

|

|

||||

|

Damp Heat Test

|

ISO6270

|

GB/T1740-1979

|

>1000 hours

|

|

||||

|

Heat Resistance

|

110°C/24 hours(white)

|

|

Good gloss retention, E≤0.3-0.4

|

|

||||

|

Florida Weathering Exposure

|

ISO2810

|

South 45 °,12mons

|

Gloss retention≥50%

|

|

||||

|

Artificial Accelerated Aging

|

60°C/8hours + 50°C/4hours ondensing, cycle for 500 hours

|

|

Gloss retention≥50%

Color stability:E≤0.35

|

|

||||

|

|

|

|

|

|

||||

|

Annotate

|

1.The above experiment uses 0.8mm steel with degreasing and rusting, and the coating thickness are 50-70 microns.

|

|

|

|

||||

|

|

2.The above coating performance may be lower as shiny and slightly lower.

|

|

|

|

||||

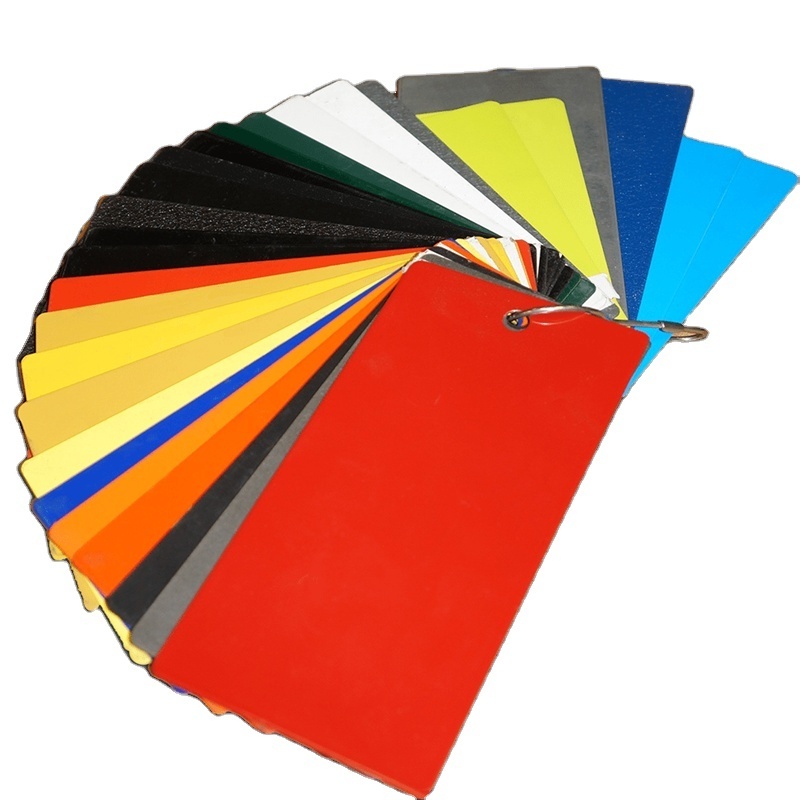

Color Model

Application

|

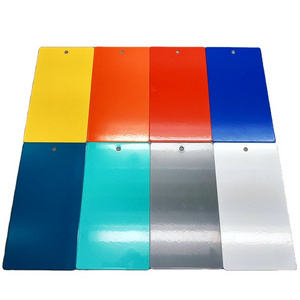

Available Powder Types

|

Available Colors

|

|

1. Epoxy powder coating

|

1. RAL Colors

|

|

2. Polyester Powder Coating

|

2. Pantone Colors

|

|

3. Epoxy-Polyester Powder Coating (Hybrid)

|

3. Customer color matching

|

|

4. Polyurethane Powder Coating

|

Available finish

|

|

5. Heat transfer printing powder coating

|

1. Smooth

|

|

Available gloss level

|

2. Rough (Sand texture)

|

|

1. High gloss( Above 80%)

|

3. Wrinkle (fine texture)

|

|

2. Flat gloss (50%-80%)

|

4. Antique (hammer tone)

|

|

3. Semi gloss(5%-50%)

|

5. Metallic

|

|

4. Matt ( below 5%)

|

6. Other special effect (artistic)

|

Hot Searches