- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

5.5KW

-

Dimension(L*W*H):

-

1740x810x1830mm

-

Weight (T):

-

6

-

Machine Type:

-

Hydraulic Press

-

Product name:

-

Ironworker Machine

-

Function:

-

Hydraulic Pounching

-

Usage:

-

Metal Sheet Punching Cutting Bending

-

Ram Stroke:

-

80mm

-

Feature:

-

Efficient

-

Material:

-

Steel Material

-

Application:

-

Metal Sheet Stamping

-

Model:

-

Deep Punching Machine

-

Machine type:

-

Hydraulic Prsee Work

Quick Details

-

Nominal Force (kN):

-

600

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

Durmapress

-

Voltage:

-

5.5KW

-

Dimension(L*W*H):

-

1740x810x1830mm

-

Weight (T):

-

6

-

Machine Type:

-

Hydraulic Press

-

Product name:

-

Ironworker Machine

-

Function:

-

Hydraulic Pounching

-

Usage:

-

Metal Sheet Punching Cutting Bending

-

Ram Stroke:

-

80mm

-

Feature:

-

Efficient

-

Material:

-

Steel Material

-

Application:

-

Metal Sheet Stamping

-

Model:

-

Deep Punching Machine

-

Machine type:

-

Hydraulic Prsee Work

Product Description

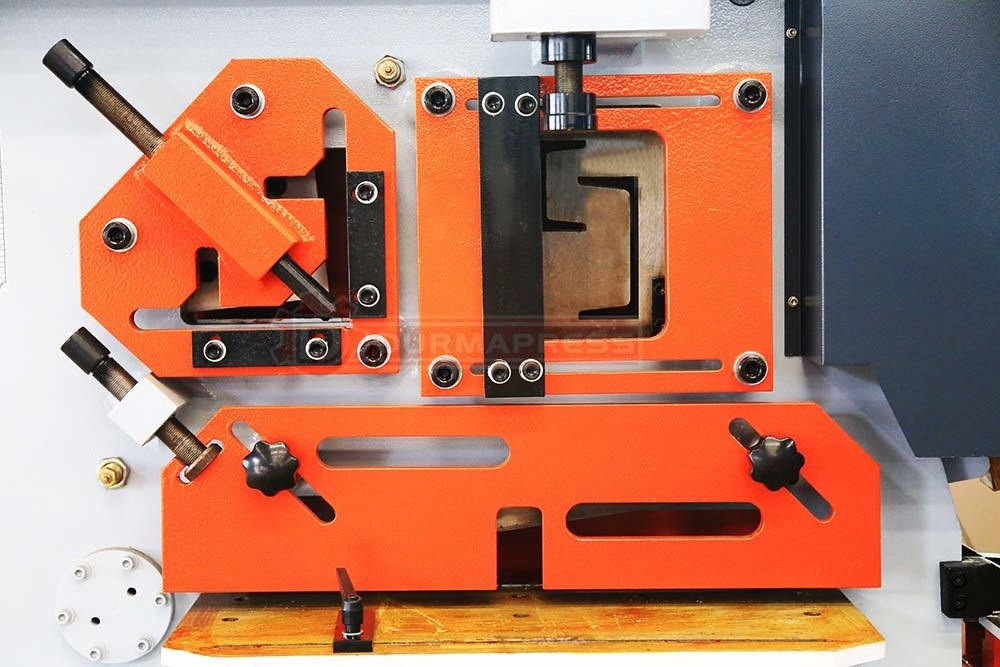

QC35Y Series Hydraulic Iron Worker

The machine design is exquisite and the structure is stable.Hydraulic transmission and mechianical conventional pressing are adopted.There are five stations, in which a is an independent station and BCDE is a combined station. The stroke of punching and shearing is adjustable.Different cutters can be selected to cut,punch,cut,chamfer and die shear flat steel, square steel ,round steel bar,angel steel,channel steel ,I-beam,Z-beam and other common soild steel materials.The worktable is equipped with T-groove and ruler,which is convenient for free installation and adjustment of tooling and die.Double foot switch,free and independent operation,double efficiency.

Detailed Images

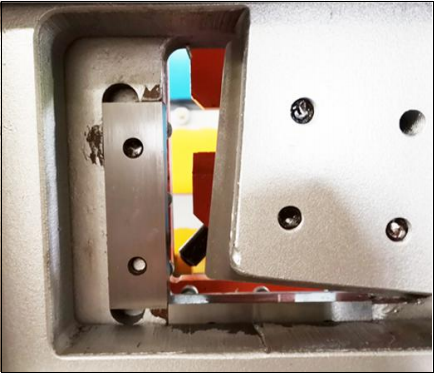

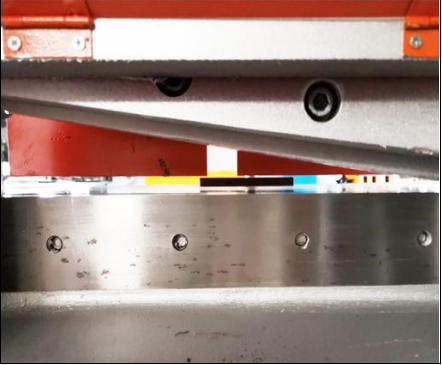

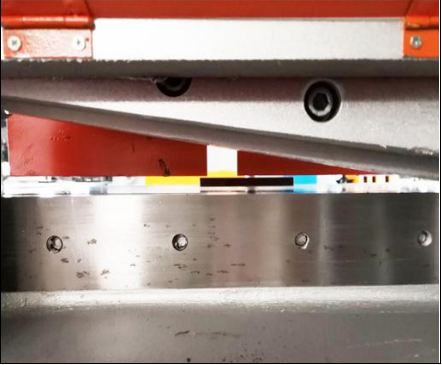

Cutting Station

The cutting position of punchine and shearing is convenient for cutting various sizes of secetion steel,and the adjustable pressing device is convenient for cutting other special secetions.

A : Flat Cutting

* Machine can cut small flat sheets , this function can be used as shearing machine .

* lt share the same working

position with round

C: Angle Cutting

steel whose length is smaller than

its Max. capacity

* Hydraulic Angle steel fixing device is

optional.

Notching

Punching Die size can be customized , You can tell us your Request , and we will make design and offer you

accurations

|

NO.

|

Item

|

Manufacturer

|

Remarks

|

|

1

|

Electrics

|

Schneider - France

|

Standard

|

|

2

|

Main Motor

|

Siemens - Beide

|

|

|

3

|

Oil pump

|

SUNNY- USA

|

|

|

4

|

Valve block

|

Rexroth - Germany

|

|

|

5

|

Pedal switch

|

KACON - South Korea

|

|

|

6

|

Wind-cooler for oil

|

China

|

|

|

7

|

Sealing ring

|

Parker-USA

|

|

|

8

|

Oil pipe connector

|

High - pressure hose-Germany

|

|

|

9

|

Safety guard

|

Durmapress Self-Made

|

|

|

10

|

Manual stopper positioning

|

Durmapress Self-Made

|

Optional

|

|

11

|

Electric stopper positioning

|

Durmapress Self-Made

|

|

|

12

|

Automatic holding system ( Manual & Automatic)

|

Durmapress Self-Made

|

|

|

13

|

Infrared ray positioning ( Punching position )

|

China

|

|

|

14

|

Tandem (punching part and shearing part can be operated separately at the same time)

|

Durmapress Self-Made

|

|

Standard Components :

* A set of punch and die(round hole)

* A set of angle steel blade

* A set of shearing plate blade

* A set of notching blade

* 2 independent hydraulic piston rods and foot-pedal allows two people operating at the same time

* More efficient stroke-control functions of piston rod Central lubricating systeMotor-driven rear stopper

* Lighting devices for work

* A set of angle steel blade

* A set of shearing plate blade

* A set of notching blade

* 2 independent hydraulic piston rods and foot-pedal allows two people operating at the same time

* More efficient stroke-control functions of piston rod Central lubricating systeMotor-driven rear stopper

* Lighting devices for work

* 5 independent work-positions

Notes :

The above moulds will be installed in the machine , safety guards are also fitted as standard on all working

stations . For other dies and blades , customers need to order and pay additionally

stations . For other dies and blades , customers need to order and pay additionally

|

Type

|

Q35Y-16

|

Q35Y-20

|

Q35Y-25

|

Q35Y-30

|

Q35Y-40

|

|

Punching pressure(Ton)

|

60

|

90

|

120

|

160

|

200

|

|

Max.shearing thickness(mm)

|

16

|

20

|

25

|

30

|

40

|

|

plate strength(N/mm2)

|

<=450

|

<=450

|

<=450

|

<=450

|

<=450

|

|

angle of shearing(degree)

|

7°

|

8°

|

8°

|

8°

|

8°

|

|

shearing size of one stroke(mm)

|

16X250 8X400

|

20X330

10X480

|

25X330

16X600

|

30X335 20X600

|

40X335

30X600

|

|

ram strock(mm)

|

80

|

80

|

80

|

80

|

100

|

|

number of stockes(cpm)

|

11-20

|

12-20

|

8-18

|

6-16

|

6-16

|

|

throat depth(mm)

|

300

|

355

|

400

|

600

|

530

|

|

punching thickness(mm)

|

16

|

20

|

25

|

28

|

35

|

|

max.punching diameter(mm)

|

25

|

30

|

35

|

35

|

40

|

|

power of main motor(kw)

|

5.5

|

7.5

|

11

|

15

|

18.5

|

|

overall dimensions(L*W*H)(mm)

|

1740X810X1830

|

1950X900X1950

|

2355X960X 2090

|

2800X1050X2450

|

2900X1100X2500

|

|

weight machine (KG)

|

2100

|

2800

|

4300

|

6800

|

9800

|

Features:

The Hydraulic Ironworker adopts hydraulic transmission. It is the latest product of the domestic multi-functional combined punching and shearing machine. It can cut, punch, die cut flat steel, square steel, round steel, angle steel, channel steel, and I-beam. Equipped with shear stop device. It is a machine tool that integrates multiple functions such as metal shearing, punching, plate shearing, bending, etc. It has the advantages of simple operation, low energy consumption, and low maintenance cost.

The structure includes:

* Punching station

* Section cutting station

* Angle Cutting station

* Shearing station

* Notching station

The structure includes:

* Punching station

* Section cutting station

* Angle Cutting station

* Shearing station

* Notching station

FAQ

Q: How to get a accurate quotation from us ?

A:Please provide us the details of material , max thickness and max width .

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% T/T ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the video directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant.

Right and left, backside all with safetyguard guarantees operations safety.

A:Please provide us the details of material , max thickness and max width .

Q:Can you do OEM service ?

A:Yes, we can. your design is accepted , your own logo can be used on the machine.

Q:What's the shipping cost from china to your country ?

A:We can send machine to your port or door address by sea or airplane. please kindly tell us your nearest port or address with postcode. we have reliable shipping agent to insure the safe convenient and time delivery.

Q:Do you accept LC payment ?

A:Yes, normally our payment is 30%+70% T/T ,LC payment is also acceptable

Q:How to operate this machine ?

A:Video line of our factory or we send you the video directly.

Q:What about commissioning service ?

A: We can offer commissioning service , the buyer need to afford plane tickets.

Q:Do you offer teaching & training ?

A:Training at supplier's plant.

Right and left, backside all with safetyguard guarantees operations safety.

Hot Searches