- Product Details

- {{item.text}}

Quick Details

-

Bending Precision (Deg):

-

0.01

-

Place of Origin:

-

Anhui, China

-

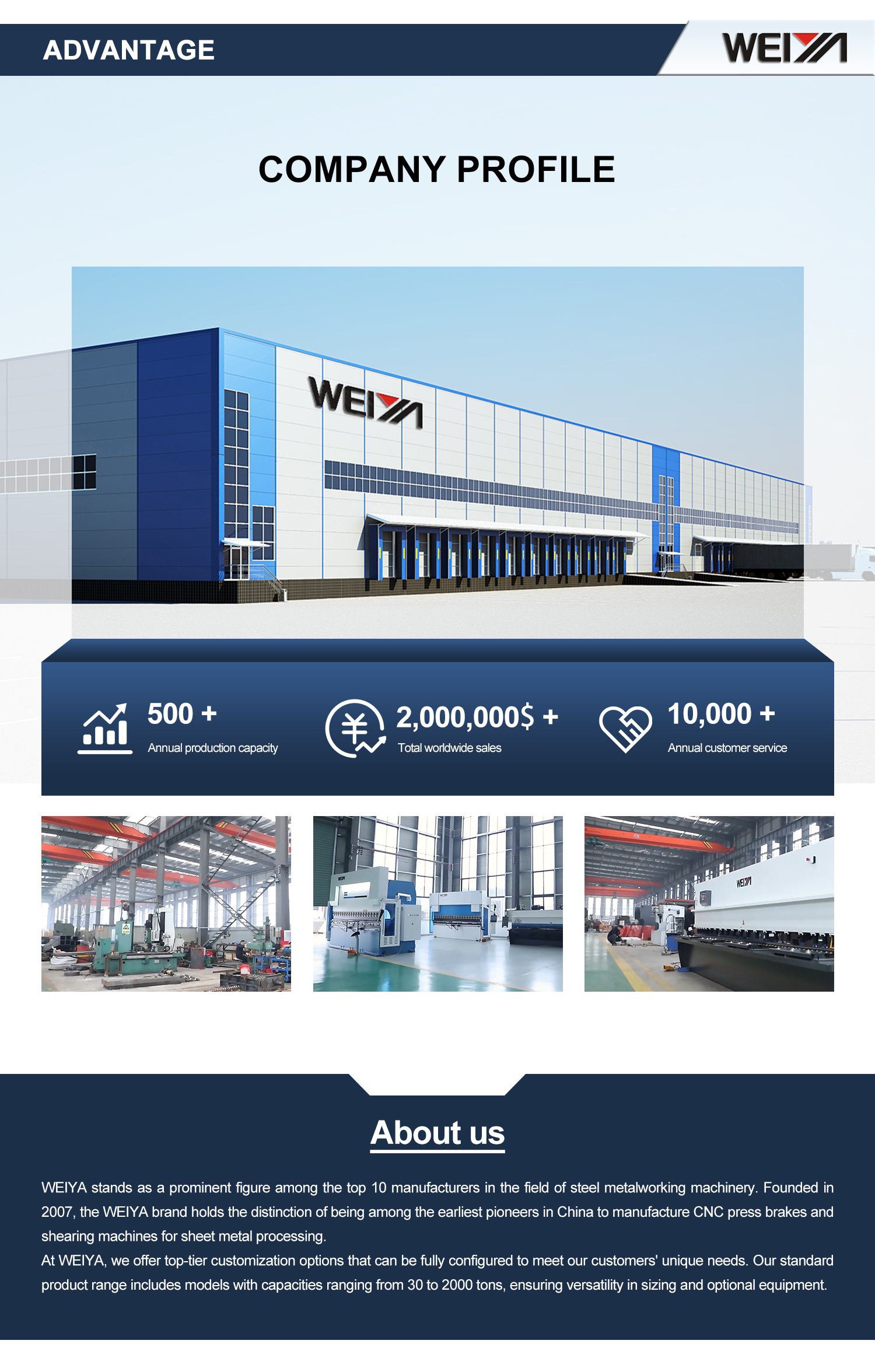

Brand Name:

-

WEIYA

-

Power (kW):

-

11

-

Weight (KG):

-

4500

-

Marketing Type:

-

New Product 2024

-

Material/Metal Processed:

-

ALLOY, Brass / Copper, Carbon steel, Stainless steel, Aluminum

-

Maxi. Diameter thickness:

-

89.5

-

Product name:

-

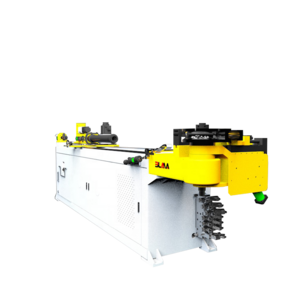

Pipe Profile Bending Machine

-

Voltage:

-

110V/220V/380V/415V/440V/customized

-

Control:

-

PLC---Delta

-

Application:

-

Pipes Processing

-

Usage:

-

Pipe Tube Bending

-

Motor power:

-

18.5KW

-

PLC:

-

Japan Mitsubishi

Quick Details

-

Machine Type:

-

Tube Bending Machine

-

Bending Radius (mm):

-

11 - 80, R510

-

Max. Bending Angle (Deg):

-

30

-

Bending Precision (Deg):

-

0.01

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

WEIYA

-

Power (kW):

-

11

-

Weight (KG):

-

4500

-

Marketing Type:

-

New Product 2024

-

Material/Metal Processed:

-

ALLOY, Brass / Copper, Carbon steel, Stainless steel, Aluminum

-

Maxi. Diameter thickness:

-

89.5

-

Product name:

-

Pipe Profile Bending Machine

-

Voltage:

-

110V/220V/380V/415V/440V/customized

-

Control:

-

PLC---Delta

-

Application:

-

Pipes Processing

-

Usage:

-

Pipe Tube Bending

-

Motor power:

-

18.5KW

-

PLC:

-

Japan Mitsubishi

Product Description

CNC Pipe Bending Machine

The WEIYA CNC pipe bending machine boasts automatic error detection, promptly displaying faults on-screen for easy

troubleshooting. Material inputs are streamlined via the touch screen interface. For varying materials, compensation data, speed,and release gap can be adjusted at each bending step. Additionally, the machine allows for programming five action sequences and ten running speeds for each bend, optimizing efficiency and minimizing pipe interference. Servo motors drive the bending control and corner feeding, ensuring high precision and efficiency, making it ideal for intricate pipe fittings with numerous angles and stringent precision requirements.

troubleshooting. Material inputs are streamlined via the touch screen interface. For varying materials, compensation data, speed,and release gap can be adjusted at each bending step. Additionally, the machine allows for programming five action sequences and ten running speeds for each bend, optimizing efficiency and minimizing pipe interference. Servo motors drive the bending control and corner feeding, ensuring high precision and efficiency, making it ideal for intricate pipe fittings with numerous angles and stringent precision requirements.

Specification

|

Model

|

WY-50CNC-2/3A-1S

|

WY-75CNC-2/3A-1S

|

WY-89CNC-2/3A-1S

|

|

CNC/Full Automatic 2/3A

|

hydraulic/electric bending 1s:1stack

|

hydraulic/electric bending 1s:1stack

|

hydraulic/electric bending 1s:1stack

|

|

Max Bending Capacity

|

50.5(2.5'')*4mm

|

75(2.5'')*4mm

|

89(2.5'')*4mm

|

|

Bending Degree

|

0-190°

|

0-190°

|

0-190°

|

|

Bending Radius

|

30-300mm(for machine)

|

30-300mm(for machine)

|

30-300mm(for machine)

|

|

Min Bending Radius

|

R≥1.4D(for pipe)

|

R≥1.4D(for pipe)

|

R≥1.4D(for pipe)

|

|

Mandrel Length

|

3800mm(can be customized)

|

3800mm(can be customized)

|

3800mm(can be customized)

|

|

Max.Bending Speed

|

80°/s

|

80°/s

|

80°/s

|

|

Max.Rotating Speed

|

180°/s

|

180°/s

|

180°/s

|

|

Max.Feeding Speed

|

800mm/s

|

800mm/s

|

800mm/s

|

|

Bending Accuracy

|

±0.1°/±0.05°

|

±0.1°/±0.05°

|

±0.1°/±0.05°

|

|

Rotating Accuracy

|

±0.05°

|

±0.05°

|

±0.05°

|

|

Feeding Accuracy

|

±0.05mm

|

±0.05mm

|

±0.05

|

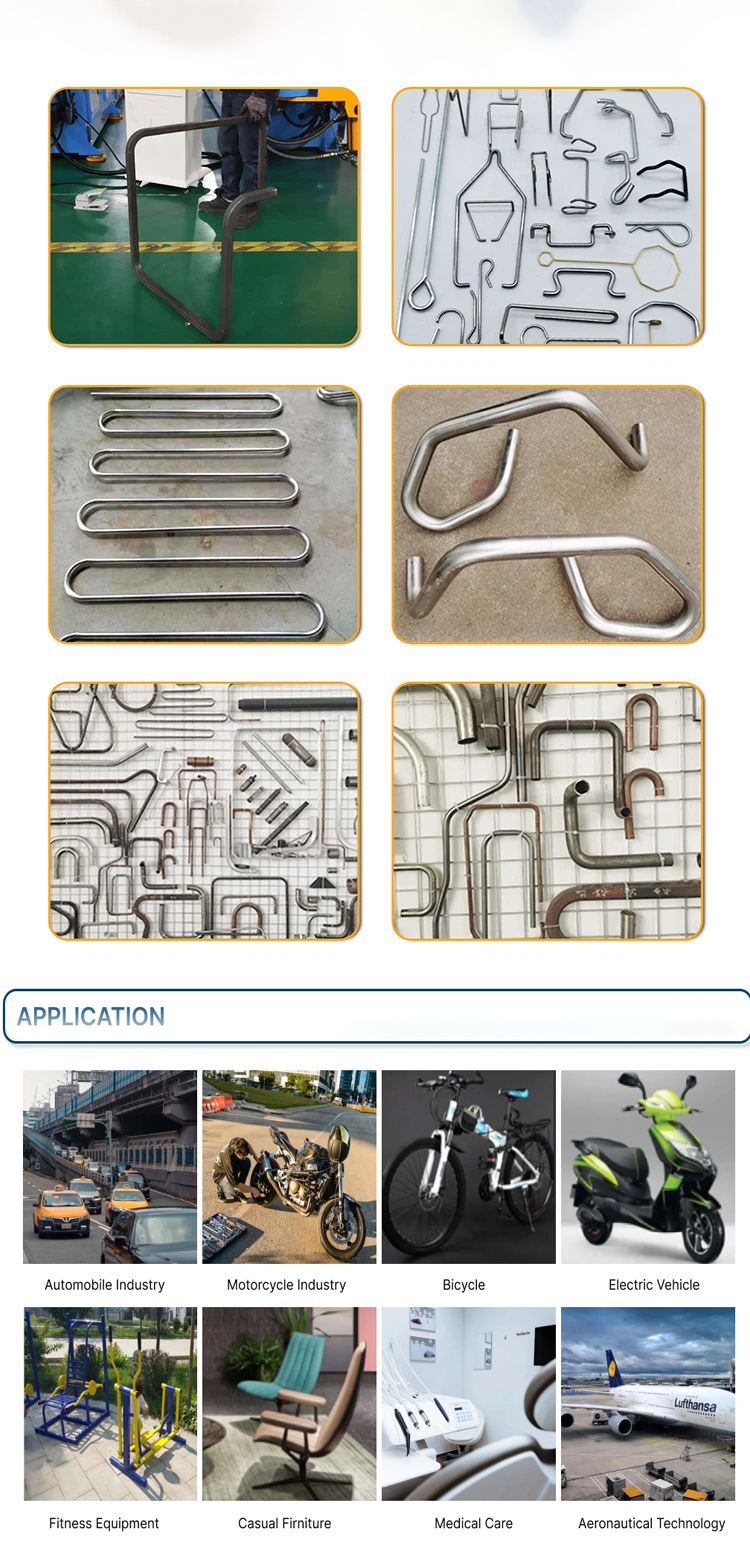

Bending Sample

Contact Us

Hot Searches