- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

1500*1100*950

-

Weight:

-

450 kg

-

Product name:

-

catfish food extruder for poultry

-

Capacity:

-

100-150kg/h

-

Raw material:

-

corn flour, wheat flour, soyabean flour, fish meal, bone meal

-

Function:

-

Producing Animal Feeds Pellets

-

Material:

-

carbon steel

-

Screw diameter (mm):

-

60mm

-

Electric Part:

-

china brand

-

Package:

-

woodcase

-

Products pellet size:

-

1.0-10mm

Quick Details

-

Max. Capacity:

-

100kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FLD

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

1500*1100*950

-

Weight:

-

450 kg

-

Product name:

-

catfish food extruder for poultry

-

Capacity:

-

100-150kg/h

-

Raw material:

-

corn flour, wheat flour, soyabean flour, fish meal, bone meal

-

Function:

-

Producing Animal Feeds Pellets

-

Material:

-

carbon steel

-

Screw diameter (mm):

-

60mm

-

Electric Part:

-

china brand

-

Package:

-

woodcase

-

Products pellet size:

-

1.0-10mm

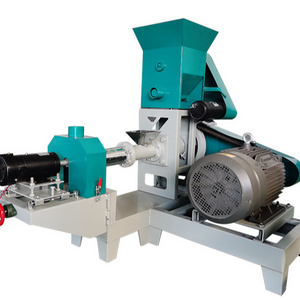

Fish food extruder machine low consumption fish feed pellet making machine 2mm catfish food extruder for poultry

1.Fish food extruder machine Application:

Fish feed extruder can be used to produce dog food, cat food, meanwhile it can produce fish pellets; the pellets size can be from 1.5mm to 15mm by adjusting the molds from extruder.

Raw materials of Fish food extruder machine:

The raw material is: Flour,corn meal,soybean meal,maize meal ,meat meal,bone meal,fish meal etc.

Fitness: about 60-80mesh which were crushed and mixed.

Moisture content: about 20%-25%.

2.Fish food extruder machine Model:

|

Model |

Power |

Capacity |

Feeding power |

Cutting power |

|

DGP40 |

5.5kw |

30-40KG/H |

0.4KW |

0.4KW |

|

DGP50 |

11KW |

60-80KG/H |

0.4KW |

0.4KW |

|

DGP60 |

15KW |

120-150KG/H |

0.4KW |

0.4KW |

|

DGP70 |

18.5KW |

180-250KG/H |

0.4KW |

0.4KW |

|

DGP80 |

22KW |

300-350KG/H |

0.4KW |

0.6KW |

|

DGP90 |

37KW |

400-500KG/H |

1.1KW |

1.5KW |

|

DGP120 |

55KW |

500-600KG/H |

1.1KW |

1.5KW |

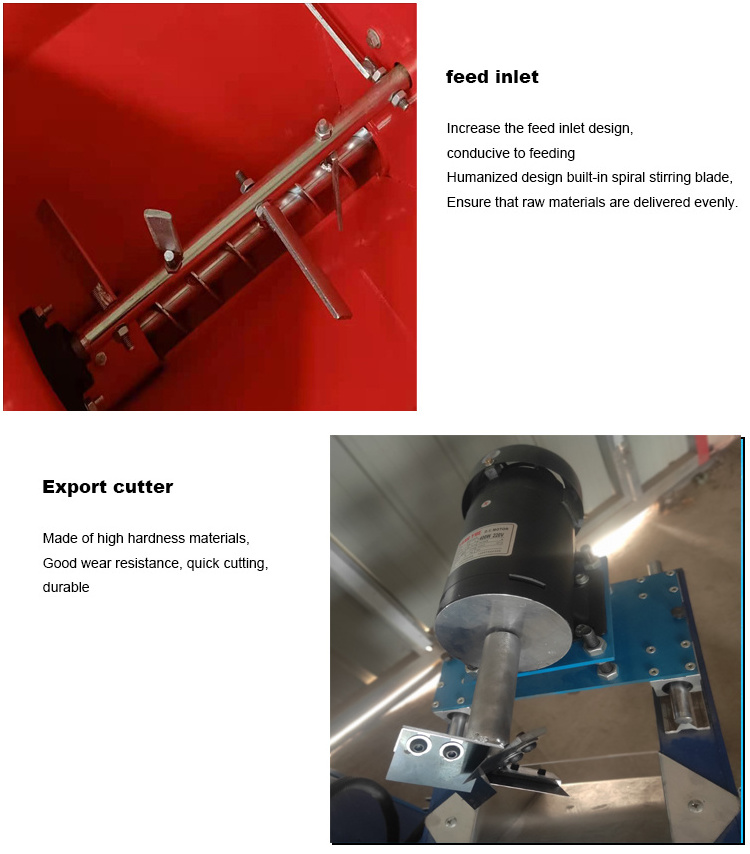

3.Produts details of Fish food extruder machine:

5.Final Pellet

Round Shape and other shapes

Diameter:0.9-15mm by replace the moulds

1).The fish feed pellets can float on water for over 20 hours.And sinking and floating aqua-feed pellets both can be made just by adjusting the feed formulation.

2). Pellet diameter is 0.9mm-15mm by changing the mold.The cutter can cutting the pellets into different length.

3)The feeding speed,cutting speed,temperature all can be adjusted.

4).The machine also can make feed for pet like dog,cat with different shapes and we can customized the shape for you.

1. 1 year guaranteed time with 24 hours service.

2. Free training, Guidance Installation and Debugging. If needed, engineers can be sent to your factory for installation and commissioning, training.

3. English manual and video for installation & operation.

4. Any problem in operation or others about the machine, you can contact with me and we will give solution in 24-48 hours.

If you are interested in our low consumption fish feed pellet making machine 2mm catfish food extruder for poultry,Please leave message to us!

1. What’s the difference between dry type extruder and wet type extruder?

The difference is the wet type need a steam boiler while the dry type doesn’t. The dry type is cheaper than wet type, and the feed pellets made by wet type extruder is much smooth and with better quality.

2. How long does the floating fish pellet float on the water surface?

The feed pellets can float on the water surface for over 20 hours.

3. Does the fish pellet machine can only make feed pellets for fish?

No. It’s not only can make high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc., but also can make pellets for chicken,cat, dog, etc.

4. Do you supply the whole fish feed production line?

Yes. We can supply a fish feed product line include crusher, mixer, fish feed pellet machine, feed pellet dryer, fish feed pellet cooler, oil spray machine and packing machine. The capacity is from 60-5000kg/h.

5. Is there a formula of making fish feed pellet?

We can offer free formula to our customers.