- Product Details

- {{item.text}}

Quick Details

-

Output Speed:

-

1.7~1200rpm, 5-371 RPM

-

Weight (KG):

-

36 KG

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

EPT

-

Certification:

-

ISO9001-2008

-

Mount Position:

-

Foot Mounted

-

Housing material:

-

High-strength cast iron HT250

-

Gear material:

-

20CrMnTi

-

Input Power:

-

0.12-200KW

-

Noise(Max):

-

60-70dB

-

Gear Surface hardness:

-

HRC58°-62°

-

Input/Output shaft hardness:

-

HB220-250

Quick Details

-

Gearing Arrangement:

-

Helical

-

Output Torque:

-

470000Nm, 3.5-21700N.m

-

Input Speed:

-

750-1500rpm

-

Output Speed:

-

1.7~1200rpm, 5-371 RPM

-

Weight (KG):

-

36 KG

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

EPT

-

Certification:

-

ISO9001-2008

-

Mount Position:

-

Foot Mounted

-

Housing material:

-

High-strength cast iron HT250

-

Gear material:

-

20CrMnTi

-

Input Power:

-

0.12-200KW

-

Noise(Max):

-

60-70dB

-

Gear Surface hardness:

-

HRC58°-62°

-

Input/Output shaft hardness:

-

HB220-250

Product Description

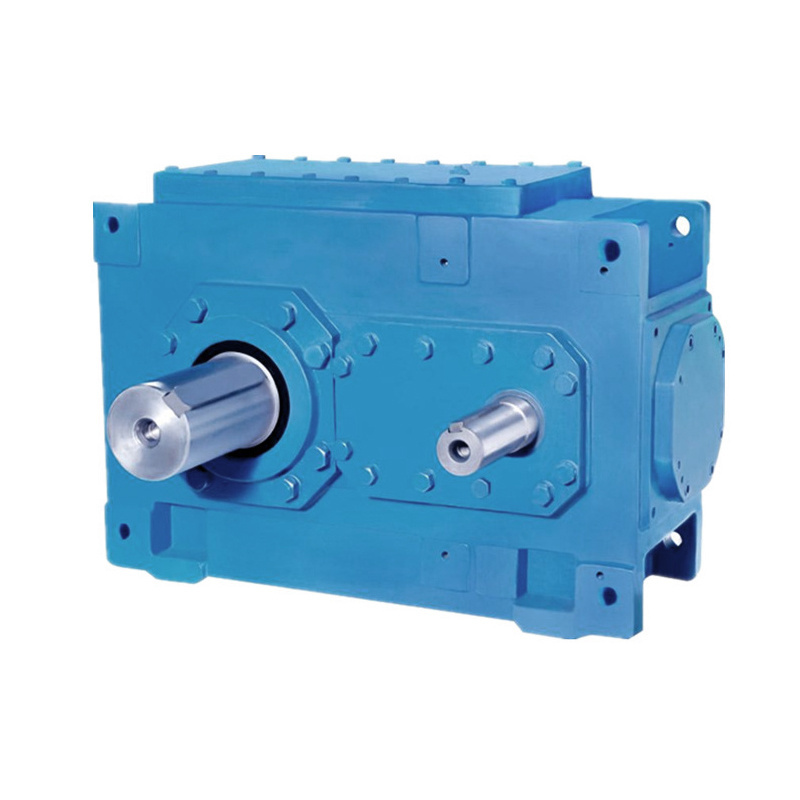

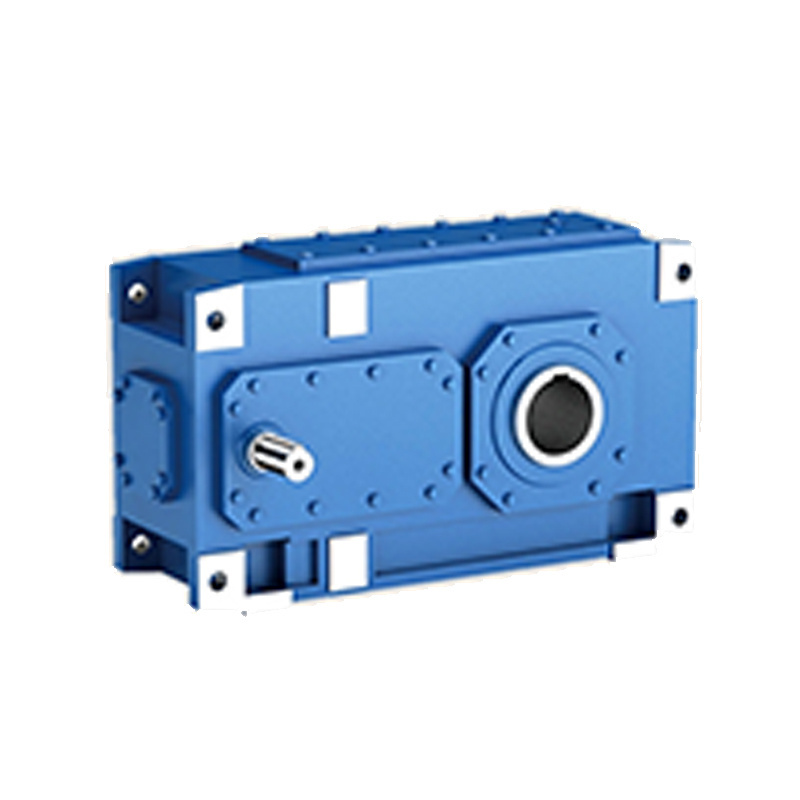

90 Degree Bevel Gear Reducer diesel engine with gear box Parallel Shaft Gear Reducer gearbox transmission

SLB series high power speed reducer has the features of high versatility,good combination and heavy loading capability, along with other merits such as easy to attain various transmission ratios, high efficiency, low vibration and high permissible axis radial load.

Specifications:

1) Output speed: 1.7~1200r/min

2) Output torque: up to 47,000N.m

3) Motor power: 2.52~5366kW

4) Mounted form: foot-mounted ,flange-mounted, axis mounted, shrink mounted

1) Output speed: 1.7~1200r/min

2) Output torque: up to 47,000N.m

3) Motor power: 2.52~5366kW

4) Mounted form: foot-mounted ,flange-mounted, axis mounted, shrink mounted

|

Housing material

|

High-strength cast iron HT250

|

|

Gear material

|

20CrMnTi

|

|

Input Power

|

0.12-200KW

|

|

Output Torque

|

3.5-21700N.m

|

|

Output Speed

|

5-371 RPM

|

|

Gear Accuracy

|

7 to 6 level

|

|

Gear Surface hardness

|

HRC58°-62°

|

|

Input/Output shaft hardness

|

HB220-250

|

|

Noise(Max)

|

60-70dB

|

|

Tem.rise(Max)

|

40°C

|

|

Tem.rise(Oil Max)

|

50°C

|

|

Vibration

|

≤20um

|

|

Backlash

|

≤20Arcmin

|

|

Effeciency

|

Single stage 98%, Double-stage:96%, Three-stage:94%

|

|

Mounting Position

|

Foot / Flange Mounting

|

|

Motor

|

IP55,F Class

|

Design

--Gear units are a completely new design. Outsanding innovations are

--More sizes with a reduced variety of parts

--Higher operational reliabilty combined with increased power capacity

--Flanged output shafts to facilitate assembly of gear units in confined spaces ( on request )

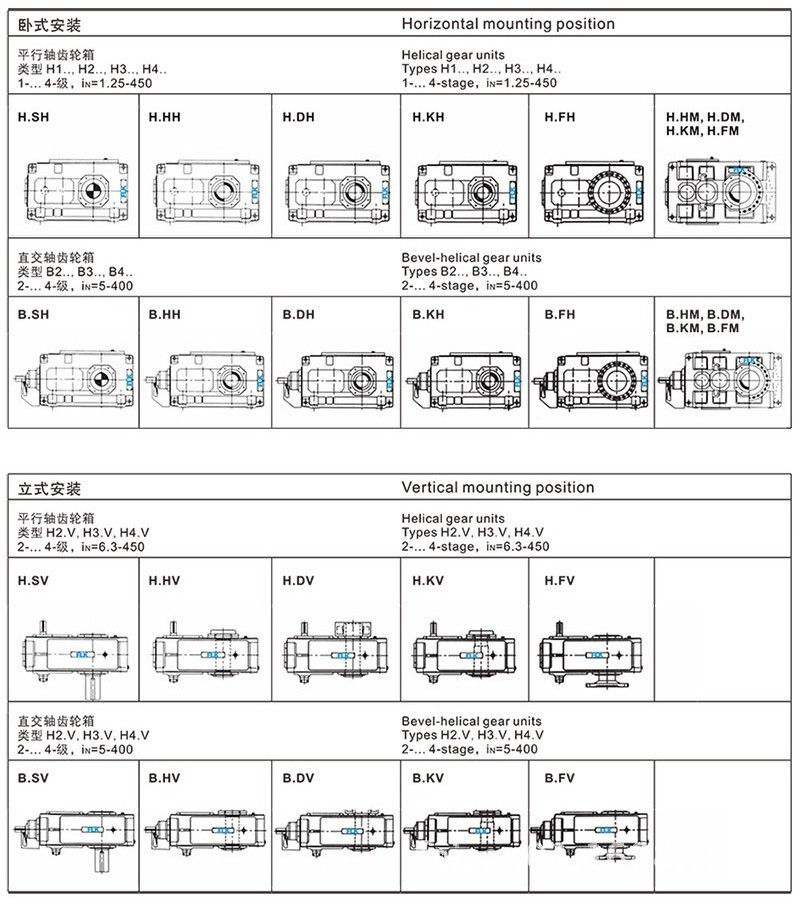

Mounting position

--Gear units can be supplied for either horizontal or vertical installation

--Other arrangements are also possible on request

--Motor bell housings , Torque supports are part of our standard productrange

Noise behaviour

--New concepts were applied to clearly improve the noise emission of the gear units

--Designing noise-absorbing housings

--Achieving exceptionally large contact ratios

Thermal conduction

gear units not only have a high efficiency but also a favourable thermal conduction

--Through enlarged housing surface areas ,

--because large fans incorporating a new type of air conduction fan cowl are being used .

--The selection of gear units is based on a lower maximum oil temperature . By that , the operational

reliability will be increased and the cost of maintenance reduced due to longer oil change intervals .

Storing

gear units have been designed according to a new unit construction principle

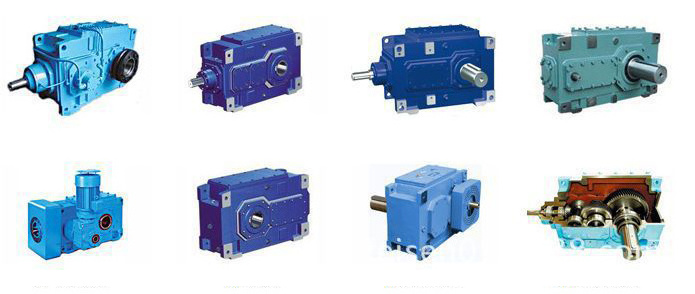

Related Products

Hot Searches