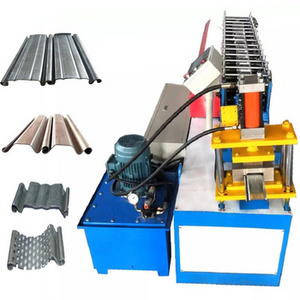

Rolling Shutter Door Making Machine load parts, decoiler loading frame we can offer different type can choose. standard type are

manual,also can choose electric loading frame or hydraulic loading frame.

This loading frame decoiler also can use in other type machine, c

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wadley

-

Voltage:

-

380 V or customized

-

Weight:

-

2500 kg

-

Product name:

-

Shutter Door Slat Forming Machine Hydraulic Door Side Roll Former

-

Application:

-

Building Construction

-

Raw material:

-

Galvanized Coil

-

Main frame:

-

350mm/400mm H-Beam

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 Mov

-

Shaft material:

-

High Grade No.45 Forged

-

Control system:

-

PLC

-

Roller stations:

-

16 Stations

-

Decoiler:

-

5T Manual Decoiler

Quick Details

-

Type:

-

Shutter Door Roll Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wadley

-

Voltage:

-

380 V or customized

-

Weight:

-

2500 kg

-

Product name:

-

Shutter Door Slat Forming Machine Hydraulic Door Side Roll Former

-

Application:

-

Building Construction

-

Raw material:

-

Galvanized Coil

-

Main frame:

-

350mm/400mm H-Beam

-

Roller material:

-

45#steel Chrome Plated

-

Cutting blade material:

-

Cr 12 Mov

-

Shaft material:

-

High Grade No.45 Forged

-

Control system:

-

PLC

-

Roller stations:

-

16 Stations

-

Decoiler:

-

5T Manual Decoiler

Product Description

Rolling shutter door machine adopts cold-formed steel door and window material made of color-coated plate and stainless steel plate, which has the characteristics of good sealing performance, beautiful appearance and long service life; composite rolling door uses cold-formed steel, which is a new type of material for fireproof doors. A large number of cold-formed steels are also used in various keels and decorative strips for decoration in the construction industry. There are many types and specifications of cross-sections required. The materials used include galvanized sheets, color-coated sheets, stainless steel and aluminum alloys

|

NO.

|

Item

|

Data

|

|

1

|

Raw material width

|

800-1200 mm

|

|

2

|

Sheet effective width

|

600-1000 mm

|

|

3

|

Raw material

|

Color steel sheet , Stainless steel or galvanized steel sheet

|

|

4

|

Material thickness

|

0.3-0.8 mm or customized

|

|

5

|

Forming roller material

|

45# steel plated with chrome

|

|

6

|

Shaft diameter

|

40 mm

|

|

7

|

Forming roll station

|

8-16 steps

|

|

8

|

Main motor power

|

3 KW 4 KW 5.5 KW(according to type)

|

|

9

|

Hydraulic power

|

4 KW (according to type)

|

|

10

|

Control system

|

PLC control

|

Details Images

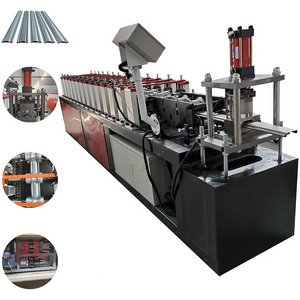

Decoiler

Machine frame

Rolling Shutter Door Making Machine adopts welded steel frame structure, it make sure roof sheet machine can operation more stable

AC frequency conversion motor reducer drive, chain transmission, roller surfaces polishing,

hard plating, heat treatment and chrome coating.

AC frequency conversion motor reducer drive, chain transmission, roller surfaces polishing,

hard plating, heat treatment and chrome coating.

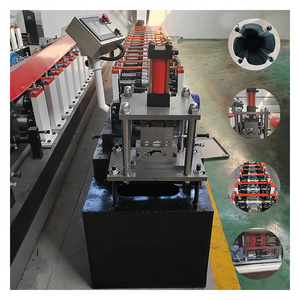

Forming roller

Rolling Shutter Door Making Machine forming roll quality will decide roof sheet shapes, we can according to your local roof shape

customized different type rollers

Roller chrome coated thickness: 0.05 mm

Roller material: Forging Steel 45# heat treatment. hydraulic station.

customized different type rollers

Roller chrome coated thickness: 0.05 mm

Roller material: Forging Steel 45# heat treatment. hydraulic station.

PLC control part

Rolling Shutter Door Making Machine control parts have different types, standard type are button control, through press buttons to

realize different function.

PLC touch screen type can setting data on the screen, its price is little higher, but is more intelligent and automatic.

realize different function.

PLC touch screen type can setting data on the screen, its price is little higher, but is more intelligent and automatic.

Successful Project

Customer feedback

Company Introduction

Henan Wadley CNC Machinery Co., Ltd.

Henan Wadley CNC Machinery Co.,Ltd. is a manufacture specializing in custom cold roll forming equipment and automatic production lines,we can manufacture hundred types roll forming machines and all kinds of architecture profliles. Engineers and technicians are rich in experience of designing developing and manufacturing of machines to provied customers with customized designs.Our products and sold to many countries and regions around the world.and we have established long-term cooperative relationships with customers.

Main products: the company operates various types of products with various specifications, including cold bending forming equipment and other mechanical equipment, such as tile pressing machine, machine tool, tapping machine, slotting machine, boring machine, air hammer, gear hobbing machine, nail making machine, marking machine, etc. Wide range of products, welcome to inquiry.

Henan Wadley CNC Machinery Co.,Ltd. is a manufacture specializing in custom cold roll forming equipment and automatic production lines,we can manufacture hundred types roll forming machines and all kinds of architecture profliles. Engineers and technicians are rich in experience of designing developing and manufacturing of machines to provied customers with customized designs.Our products and sold to many countries and regions around the world.and we have established long-term cooperative relationships with customers.

Main products: the company operates various types of products with various specifications, including cold bending forming equipment and other mechanical equipment, such as tile pressing machine, machine tool, tapping machine, slotting machine, boring machine, air hammer, gear hobbing machine, nail making machine, marking machine, etc. Wide range of products, welcome to inquiry.

FAQ

Q1. What are the main key points for selecting right machines?

A1: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price not the final point.Good quality is for long-term business cooperation.

Q2. Can you provide OEM service for roll forming machine?

A2: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q3. What’s your standard trade terms ?

A2: We can provide the technical offer with FOB,CFR,CIF,Door to Door and so on. Please kindly tell the detailed port name

for competitive ocean freight.

Q4. How about the quality control?

A4: Our company adopts 6S system to control every part with passed ISO9001:2000, CE,TUV/BV(Alibaba) Certificate.

Q5. How about the after-sale service?

A5: We provide 18 months free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.

A1: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price not the final point.Good quality is for long-term business cooperation.

Q2. Can you provide OEM service for roll forming machine?

A2: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q3. What’s your standard trade terms ?

A2: We can provide the technical offer with FOB,CFR,CIF,Door to Door and so on. Please kindly tell the detailed port name

for competitive ocean freight.

Q4. How about the quality control?

A4: Our company adopts 6S system to control every part with passed ISO9001:2000, CE,TUV/BV(Alibaba) Certificate.

Q5. How about the after-sale service?

A5: We provide 18 months free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.

Hot Searches